6-2-6

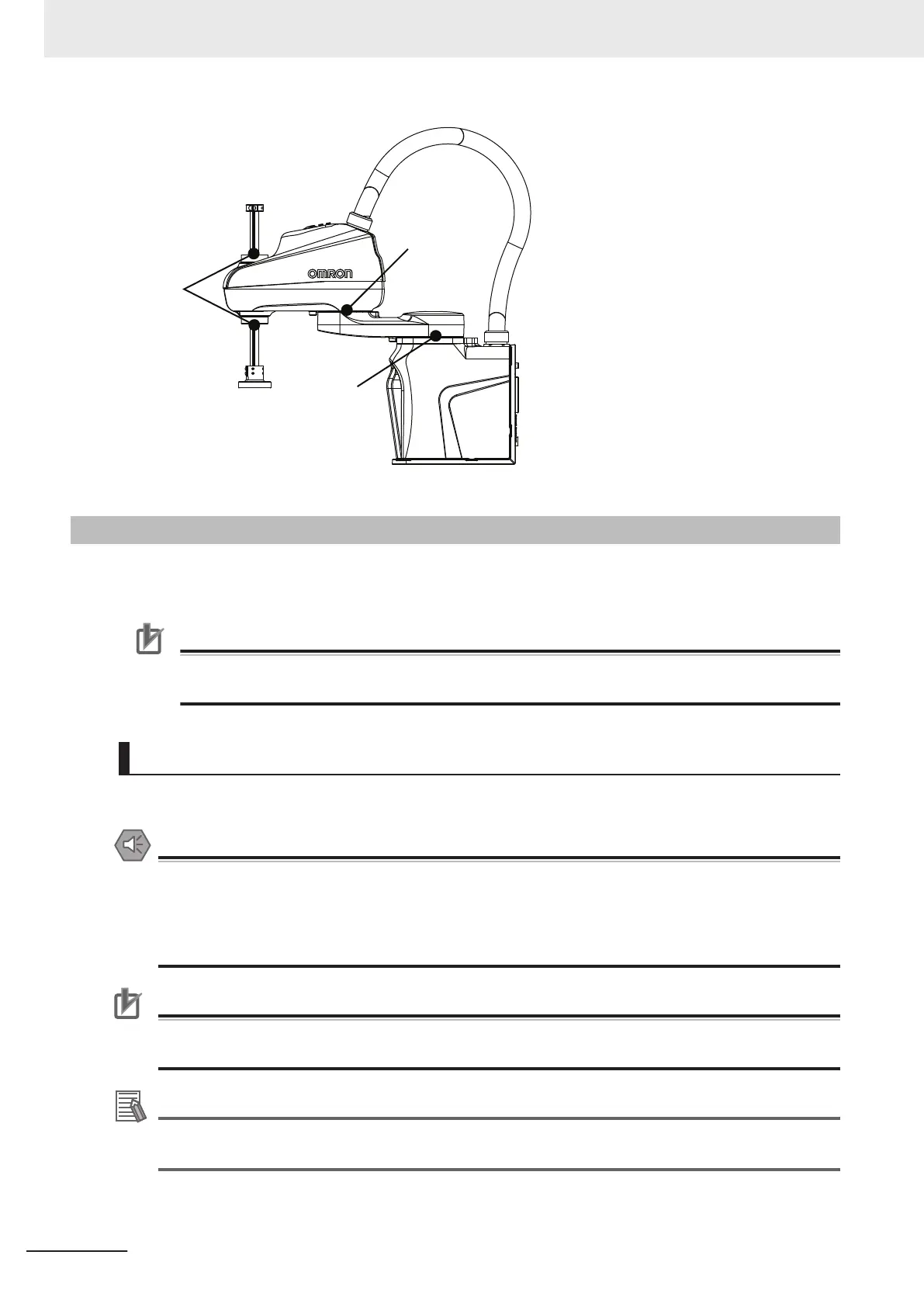

Lubricating Joint 3

The joint 3 quill needs to be lubricated on a periodic basis of 3 months or 150 km of linear travel,

whichever comes first.

Precautions for Correct Use

Only use the recommended grease on the joint 3 quill. Use THK AFF Grease (part number

20950-000). Refer to the provided Safety Data Sheet for proper handling.

Joint 3 Lubrication Procedure

Use the following procedure to lubricate joint 3.

Precautions for Safe Use

The braking mechanism operates passively. If 24 VDC Control Power is removed from the system,

the brake mechanism will automatically activate. 24 VDC Control Power must be supplied to re-

lease the brake. To prevent possible damage to the equipment, remove any payload from the end-

of-arm tooling, make sure that Joint 3 is supported while releasing the brake, and verify that the

end-of-arm tooling or other installed equipment is clear of all obstructions.

Precautions for Correct Use

Avoid rotating the quill / Joint 4 when the brake is released. This could result in an out-of-range

condition and may prevent program execution.

Additional Information

Ensure there are no z-axis motion restrictions. The full operating stroke is required during this lubri-

cation procedure.

6 Maintenance

6-6

i4L Robots User's Manual (I658)

Loading...

Loading...