5-12

CHAPTER 5 Periodic Inspection

5-2-1 R6YXH250, R6YXH350, R6YXH400

The following steps describe procedures and precautions when replacing the

harmonic drives of the R6YXH250, R6YXH350 and R6YXH400. (The illustra-

tions show the R6YXH250). For the bolt tightening torques in this work, refer

to Table 5-2.

1. X-axis

1) Prepare the following tools and items.

• Harmonic grease 4B No.2

• Waste cloth (rag)

• Phillips-head screwdriver

• Hex wrench set

• Screw Lock (thread sealant)

• Ratchet handle

• Hexagonal socket set

• Extension bar

• Torque-limiting wrench

• Replacement parts (See table below.)

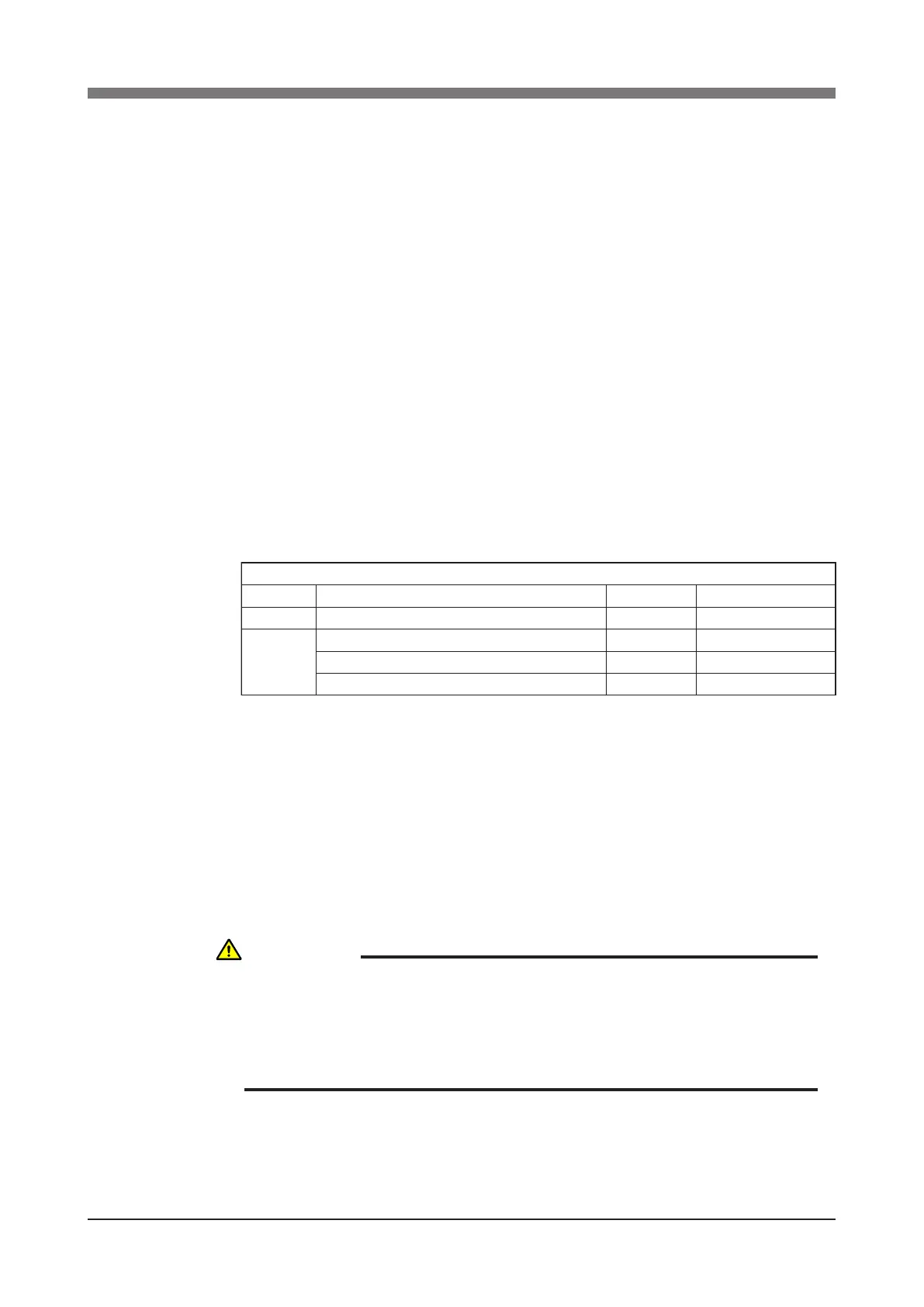

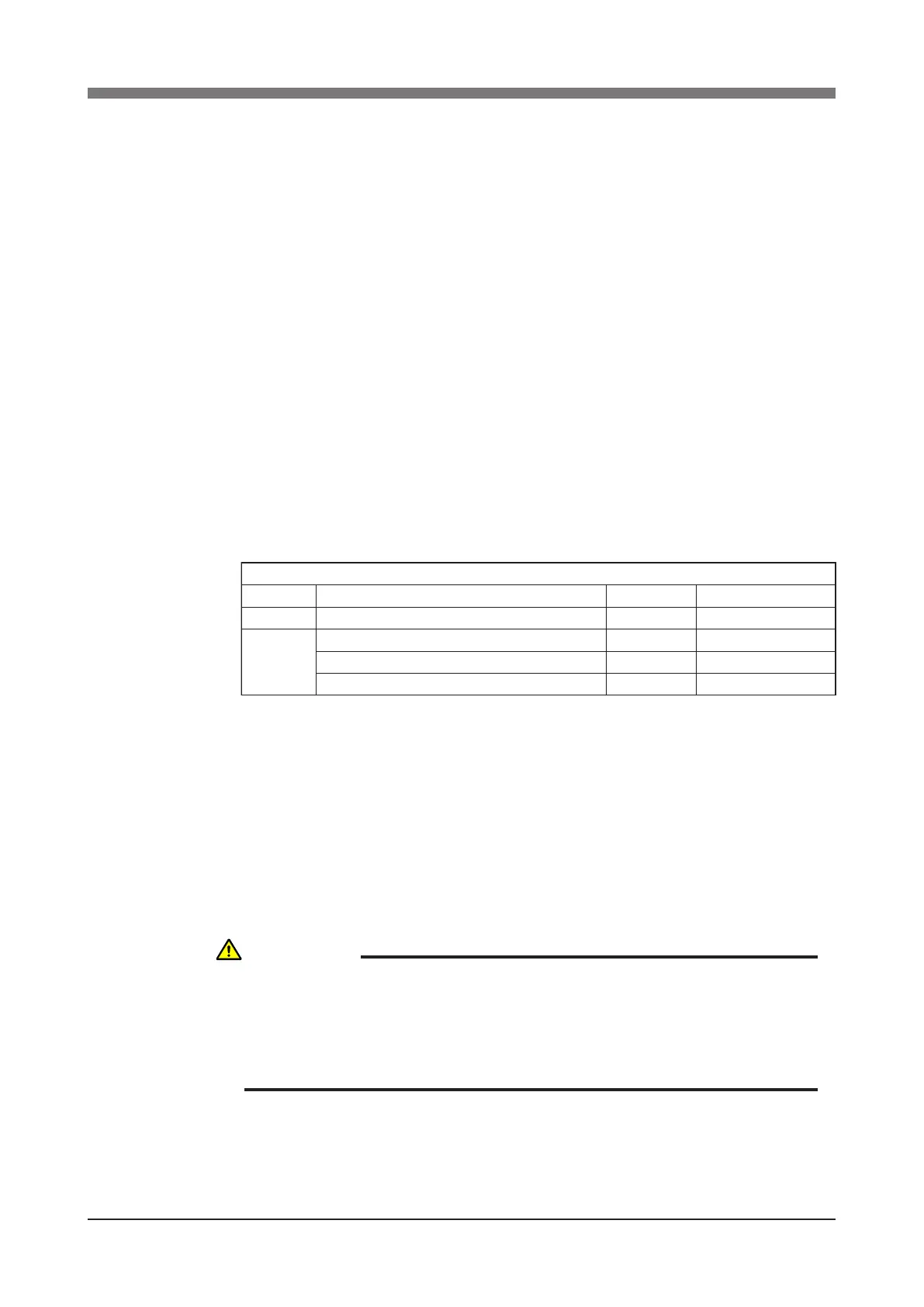

Replacement parts

Parts name

Type No .

OMRON Parts No.

Note

Harmonic drive

SHF-20-50

KN3-M2110-001

S71(JIS)

KN3-M2159-000

Top of harmonic drive

O-ring

Cross section diameter: 1.50mm x Inner diameter: 49.00mm

KN3-M2143-000

For motor

Cross section diameter: 0.99mm x Inner diameter:53.28mm

KN3-M2144-000

Supplied with harmonic drive

2) Turn off the controller.

3) Place a sign indicating that the robot is being inspected, to keep others from

operating the controller switch.

4) Enter the safeguard enclosure.

5) Remove the base (robot pedestal) front and rear covers.

Refer to "7 Removing the Robot Covers" in Chapter 4 for removing the

covers.

WARNING

WHEN YOU REMOVE THE X-AXIS ARM INSTALLATION BOLTS

(M3×40L, 8 PIECES) IN THE NEXT STEP, THE X-AXIS ARM MAY COME

OFF CAUSING A HAZARDOUS SITUATION. BE ESPECIALLY CAREFUL

TO KEEP THE ARM FROM FALLING WHEN A HEAVY TOOL IS

ATTACHED TO THE ARM TIP.

Loading...

Loading...