.

5.

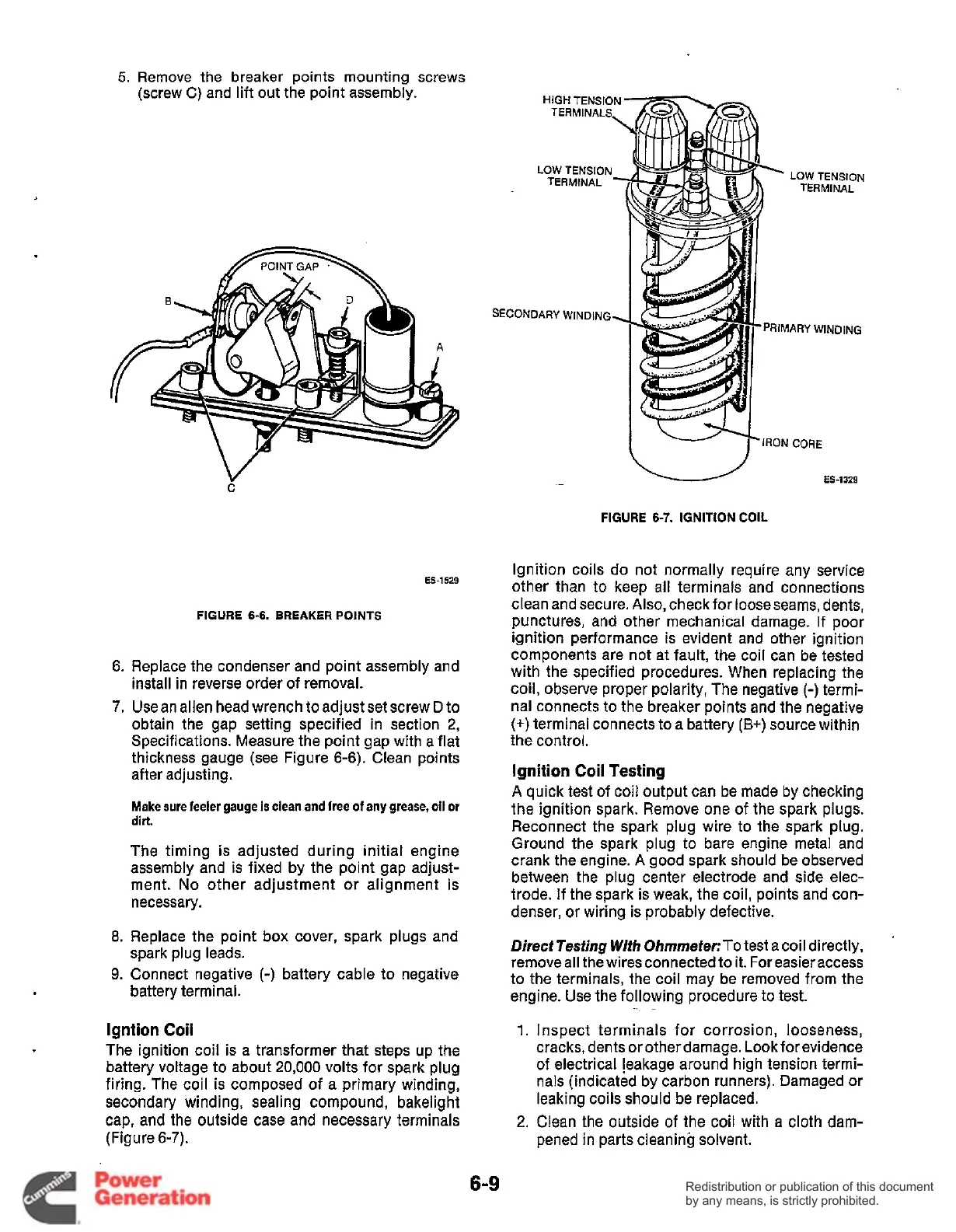

Remove the breaker

points

mounting screws

(screw C) and lift out the point assembly.

C

6.

7.

8.

ES-1529

FIGURE

6-6.

BREAKER POINTS

Replace the condenser and point assembly and

install in reverse order of removal.

Use an allen head wrench to adjust set screw

D

to

obtain the gap setting specified in section

2,

Specifications. Measure the point gap with a flat

thickness gauge (see Figure

6-6).

Clean points

after adjusting.

Make sure feeler gauge

is

clean and free

of

any grease,

oil

or

dirt.

The timing is adjusted during initial engine

assembly and is fixed by the point gap adjust-

ment.

No

other adjustment

or

alignment is

necessary.

Replace the point box cover, spark plugs and

spark plug leads.

9.

Connect negative

(-)

battery cable to negative

battery terminal.

lgntion

Coil

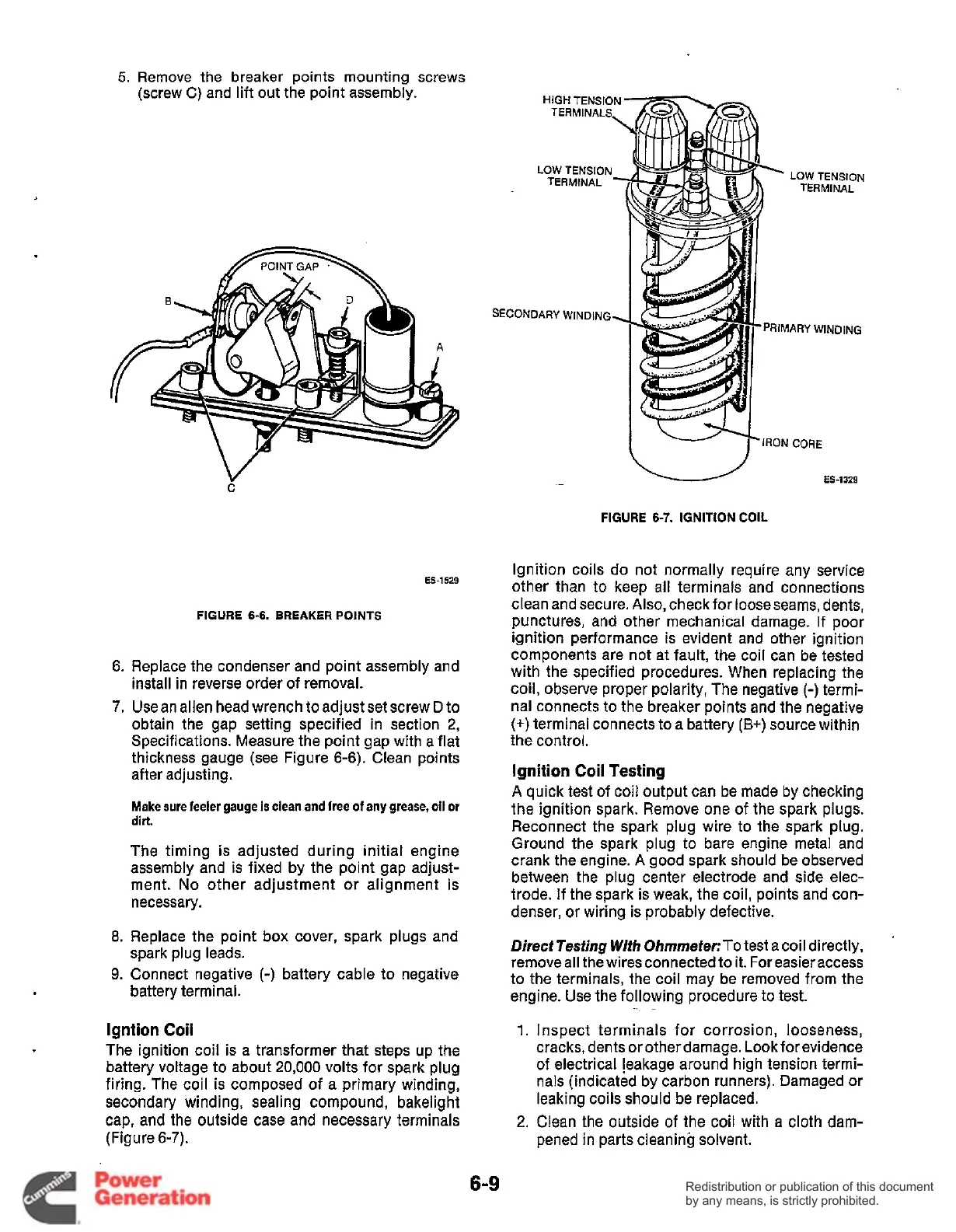

The ignition coil is a transformer that steps up the

battery voltage to about

20,000

volts for spark plug

firing. The coil

is

composed of a primary winding,

secondary winding, sealing compound, bakelight

cap, and the outside case and necessary terminals

(Figure

6-7).

SECONDARY

WINDING

PRIMARY

WINDING

-

ES-1329

FIGURE 6-7.

IGNITION

COIL

Ignition coils do not normally require any service

other than to keep all terminals and connections

clean and secure.

Also,

check for looseseams, dents,

punctures, and other mechanical damage. If poor

ignition performance

is

evident and other ignition

components are not at fault, the coil can be tested

with the specified procedures. When replacing the

coil, observe proper polarity, The negative

(-)

termi-

nal connects

to

the breaker points and the negative

(+)

terminal connects to a battery

(B+)

source within

the control.

Ignition

Coil

Testing

A

quick test

of

coil output can be made by checking

the ignition spark. Remove one of the spark plugs.

Reconnect the spark plug wire to the spark plug.

Ground the spark plug to bare engine metal and

crank the engine.

A

good spark should be observed

between the plug center electrode and side elec-

trode.

If

the spark is weak, the coil, points and con-

denser,

or

wiring is probably defective.

Direct

Testing

With

OhmmetecTo

test a coil directly,

remove all the wires connected to

it.

For easier access

to the terminals, the coil may be removed from the

engine. Use the following procedure to test.

1.

Inspect terminals for corrosion, looseness,

cracks, dents

or

other damage. Look forevidence

of electrical leakage around high tension termi-

nals (indicated by carbon runners). Damaged

or

leaking coils should be replaced.

2.

Clean the outside

of

the coil with a cloth dam-

pened in parts cleaning solvent.

6-9

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...