.

Remove

the

piston pin retainer from each side and

push the pin out.

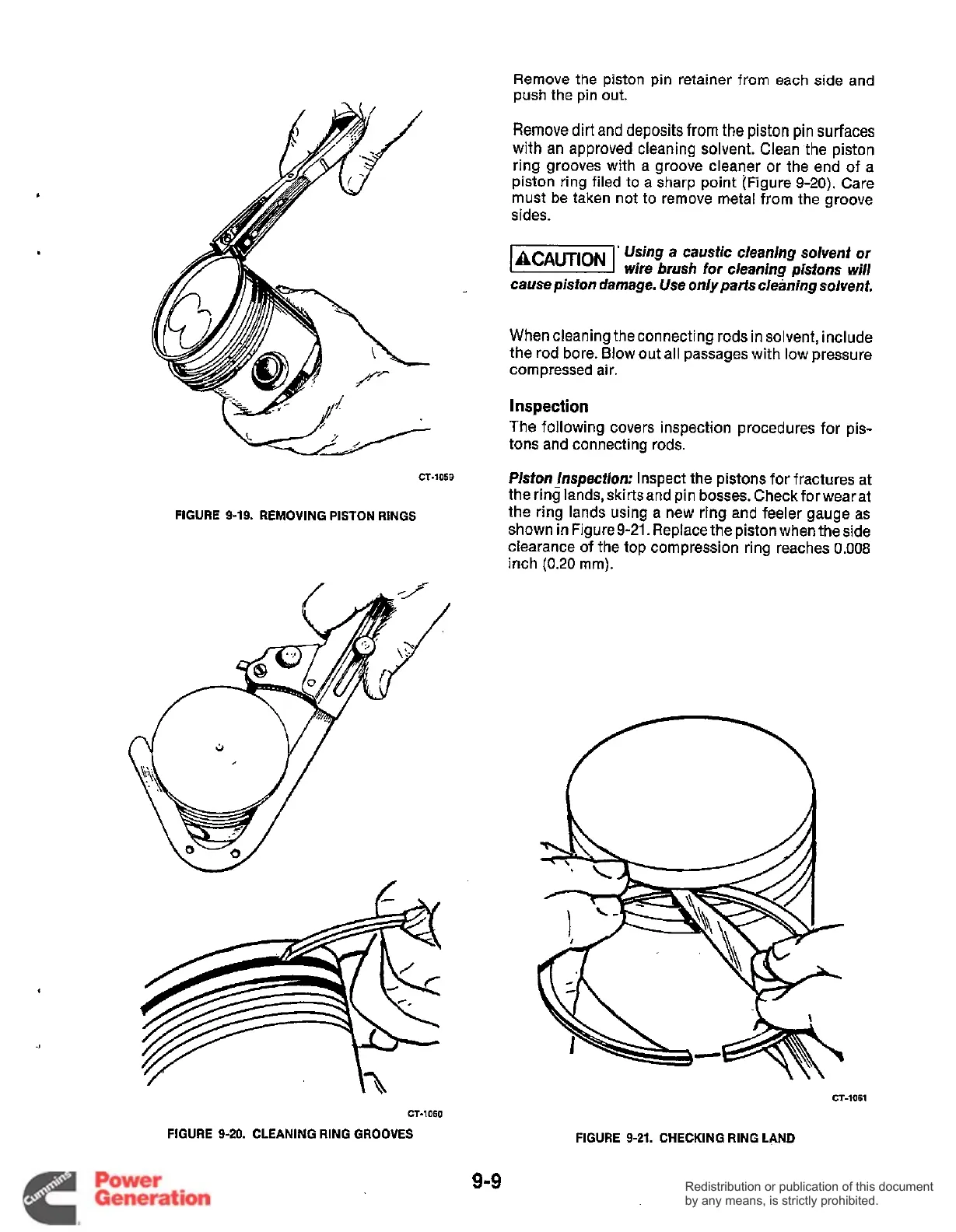

Remove dirt and deposits

from

the piston pin surfaces

with an approved cleaning solvent. Clean the piston

ring grooves with a groove cleaner or the end of a

piston ring filed to a sharp point (Figure

9-20).

Care

must be taken not to remove metal from the groove

sides.

I

Using a caustic cleaning solvent

or

lZE%Eil

wire

brush

for

cleaning pistons wii/

cause piston damage. Use only parts cleaning solvent.

When cleaning the connecting rods in solvent, include

the rod bore. Blow out all passages with low pressure

compressed air.

Inspection

The following covers inspection procedures for pis-

tons and connecting rods.

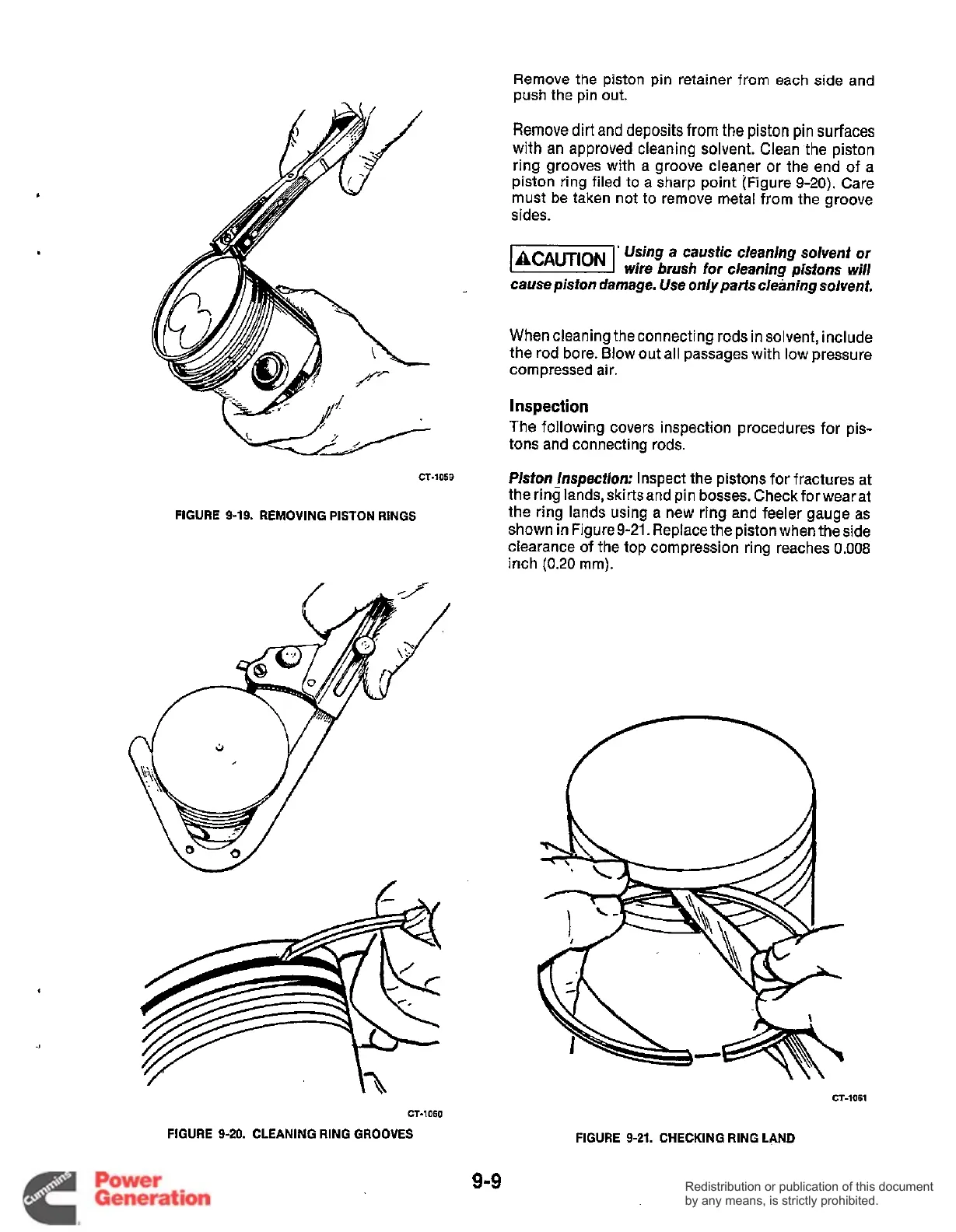

Piston Inspection:

Inspect the pistons for fractures at

the ring lands, skirtsand pin bosses. Check forwearat

the ring lands using a new ring and feeler gauge as

shown in Figure9-21. Replace the piston when the side

clearance of the top compression ring reaches

0.008

inch

(0.20

mm).

Cl-1059

FIGURE 9-19. REMOVING PISTON RINGS

CT-1060

FIGURE 9-20. CLEANING RING GROOVES

CT-1061

FIGURE 9-21. CHECKING RING

LAND

9-9

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...