.

carbon deposits. Carbon prevents heat dissipation.

Clean metal is a good heat conductor but carbon insu-

lates and retains heat. This increases combustion

chamber temperatures which causes warping and

burning.

Unburned carbon residue gums valve stems and

causes them to stick in the guide. Deposits of hard

carbon with sharp points projecting become white hot

and cause pre-ignition and “pinging”.

ValveSfemSeakAvalvestem seal is used on theintake

valve guides. This seal must be replaced each time the

valve is removed.

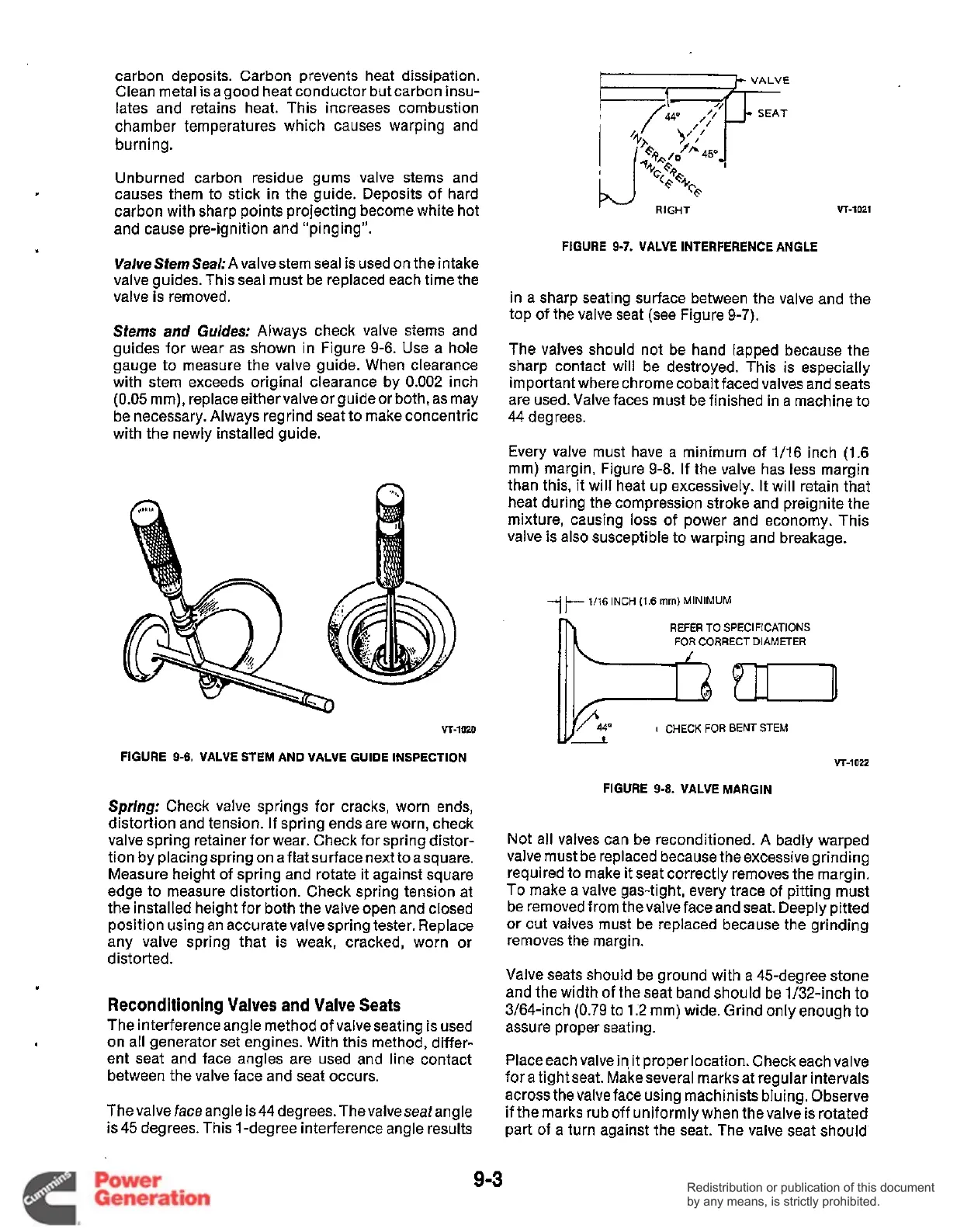

Stems

and Guides: Always check valve stems and

guides for wear as shown in Figure 9-6. Use a hole

gauge to measure the valve guide. When clearance

with stem exceeds original clearance by

0.002

inch

(0.05

mm), replaceeithervalveorguideorboth, asmay

be necessary. Always regrind seat to make concentric

with the newly installed guide.

VT-1020

FIGURE

9-6.

VALVE

STEM

AND VALVE GUIDE INSPECTION

Spring:

Check valve springs for cracks, worn ends,

distortion and tension. If spring ends are worn, check

valve spring retainer for wear. Check for spring distor-

tion by placing spring on aflat surface next to asquare.

Measure height of spring and rotate

it

against square

edge

to

measure distortion. Check spring tension at

the installed height for both the valve open and closed

position using an accurate valve spring tester. Replace

any valve spring that is weak, cracked, worn or

distorted.

Reconditioning Valves and Valve Seats

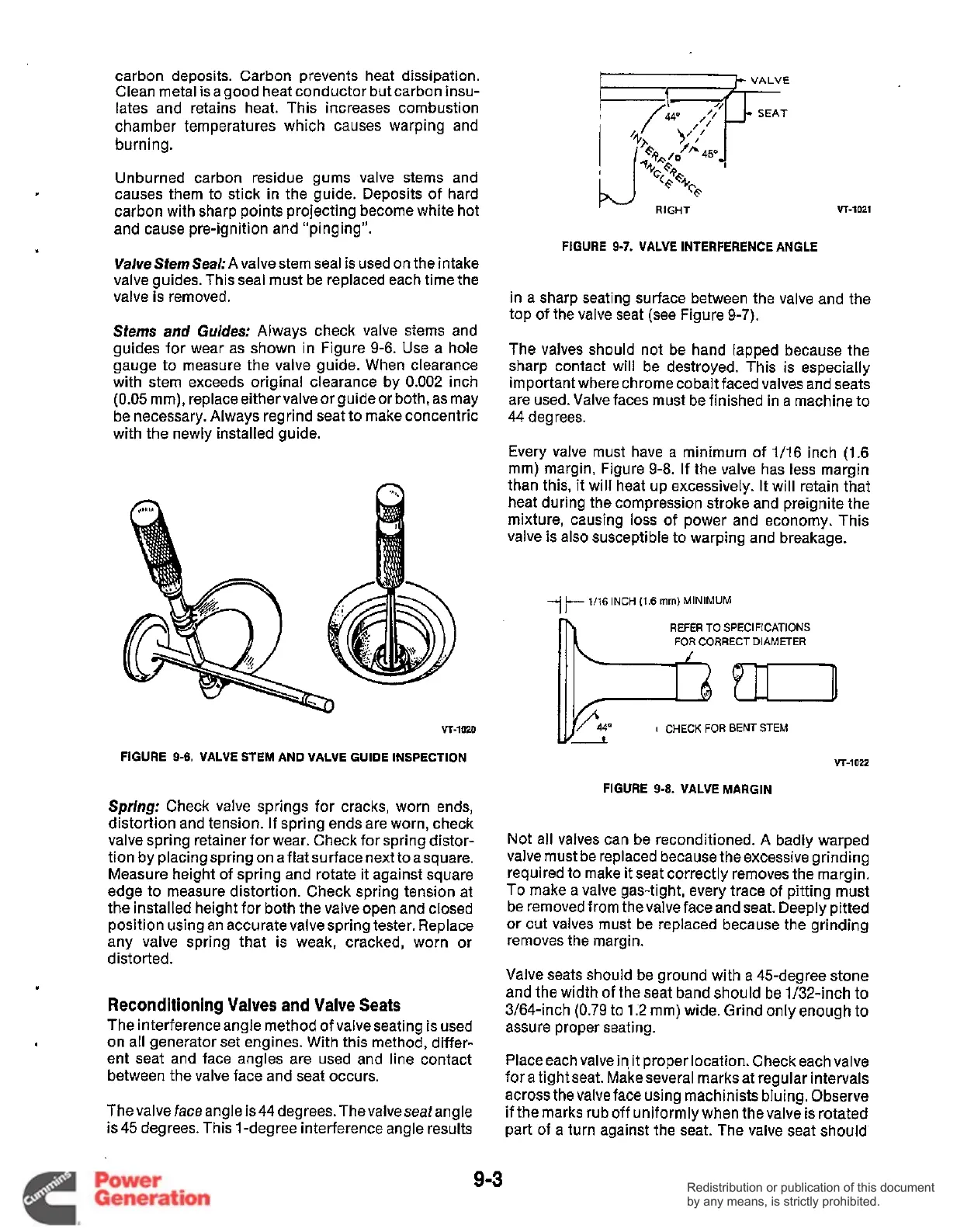

The interference angle method of valveseating is used

on all generator set engines. With this method, differ-

ent seat and face angles are used and line contact

between the valve face and seat occurs.

Thevalve faceangle is44

degrees.Theva1veseafangle

is

45 degrees. This l-degree interference angle results

VALVE

+Ad

FIGURE 9-7. VALVE INTERFERENCE ANGLE

in a sharp seating surface between the valve and the

top

of

the valve seat (see Figure

9-7).

The valves should not be hand lapped because the

sharp contact will be destroyed. This is especially

important where chrome cobalt faced valves and seats

are used. Valve faces must be finished in a machine to

44 degrees.

Every valve must have a minimum

of

1/16 inch (1.6

mm) margin, Figure 9-8. If the valve has less margin

than this, it will heat up excessively.

It

will retain that

heat during the compression stroke and preignite the

mixture, causing loss of power and economy. This

valve is also susceptible to warping and breakage.

7

1/16 INCH

(1.6

mm)

MINIMUM

REFER

TO

SPECIFICATIONS

FOR

CORRECT

DIAMETER

VT-1022

FIGURE

9-8.

VALVE MARGIN

Not all valves can be reconditioned.

A

badly warped

valve must be replaced because theexcessive grinding

required to make it seat correctly removes the margin.

To

make a valve gas-tight, every trace of pitting must

be removed from the valve face and seat. Deeply pitted

or cut valves must be replaced because the grinding

removes the margin.

Valve seats should be ground with a 45-degree stone

and the width

of

the seat band should be 1/32-inch

to

3/64-inch

(0.79

to

1.2

mm) wide. Grind onlyenough

to

assure proper seating.

Place each valve in,

it

proper location. Check each valve

fora tight seat. Makeseveral rnarksat regular intervals

across the valve face using machinists bluing. Observe

if

the marks rub

off

uniformly when the valve is rotated

part of a turn against the seat. The valve seat should

9-3

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...