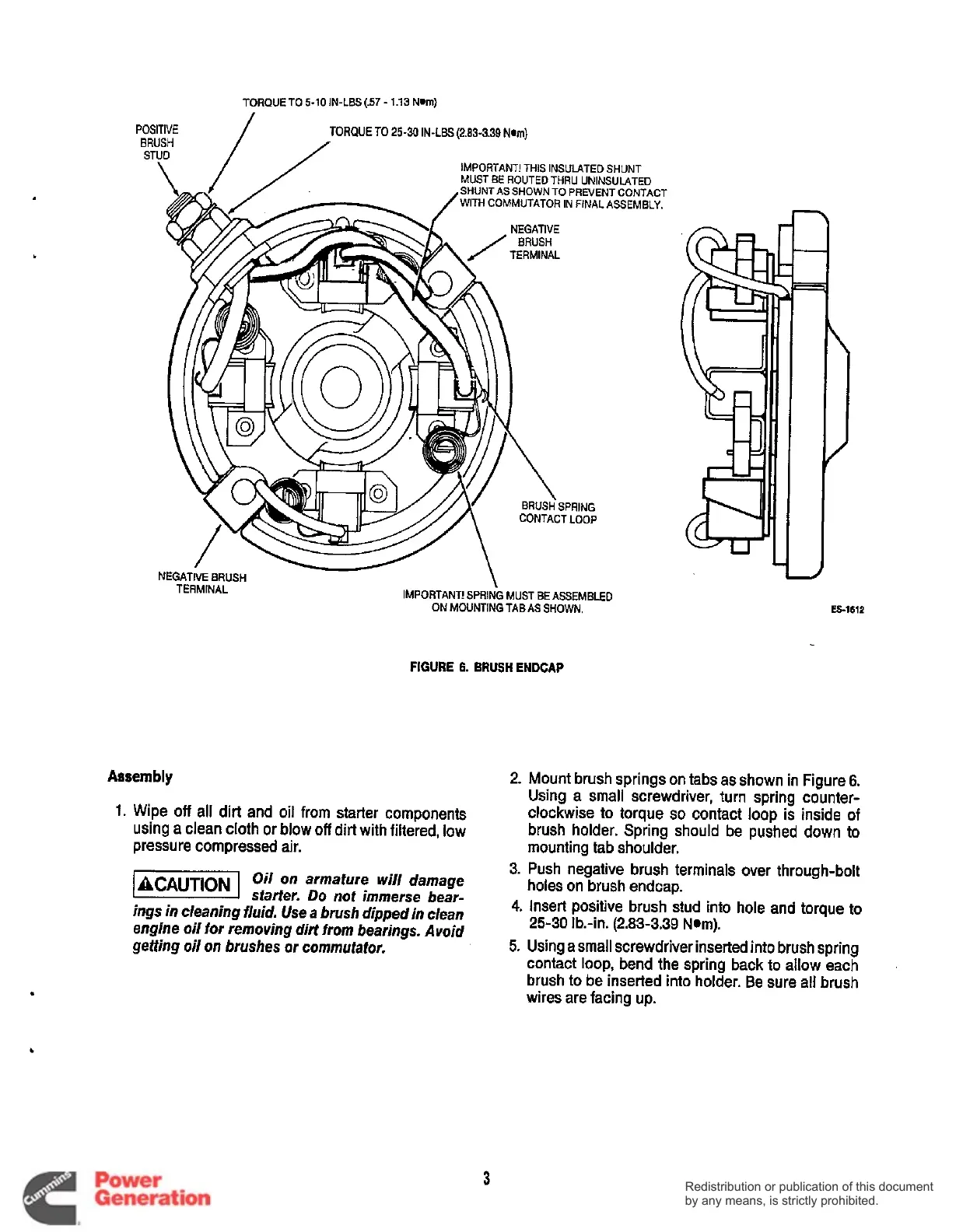

TORQUE TO

5-10

IN-LBS

(.57

-

1.13

Nm)

FIGURE

6.

BRUSH

ENDCAP

Assembly

1.

Wipe

off

all

dirt

and oil from starter components

using a clean cloth or blow

off

dirt with filtered, low

pressure compressed air.

-1

Oil on armature wi// damage

starter.

Do

not immerse bear-

ings in cleaning fluid. Use a brush dipped in clean

engine oil for removing dirt from bearings. Avoid

geffing oil on brushes or commutator.

Es-1612

2.

Mount brush springs on tabs as shown in Figure

6.

Using a small screwdriver, turn spring counter-

clockwise

to

torque

so

contact loop is inside

of

brush holder. Spring should be pushed down

to

mounting tab shoulder.

3.

Push negative brush terminals over through-bolt

holes on brush endcap.

4.

Insert positive brush stud into hole and torque to

25-30

Ib.-in.

(2.83-3.39

Nom).

5.

Using asmall screwdriver inserted into brush spring

contact loop, bend the spring back

to

allow each

brush to be inserted into holder. Be sure all brush

wires are facing up.

3

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.