Replacement:

After the

old

seat has been removed,

clean carbon or metal burrs from the seat insert

recess. Use a valve seat insert driver and a hammer to

install the inserts.

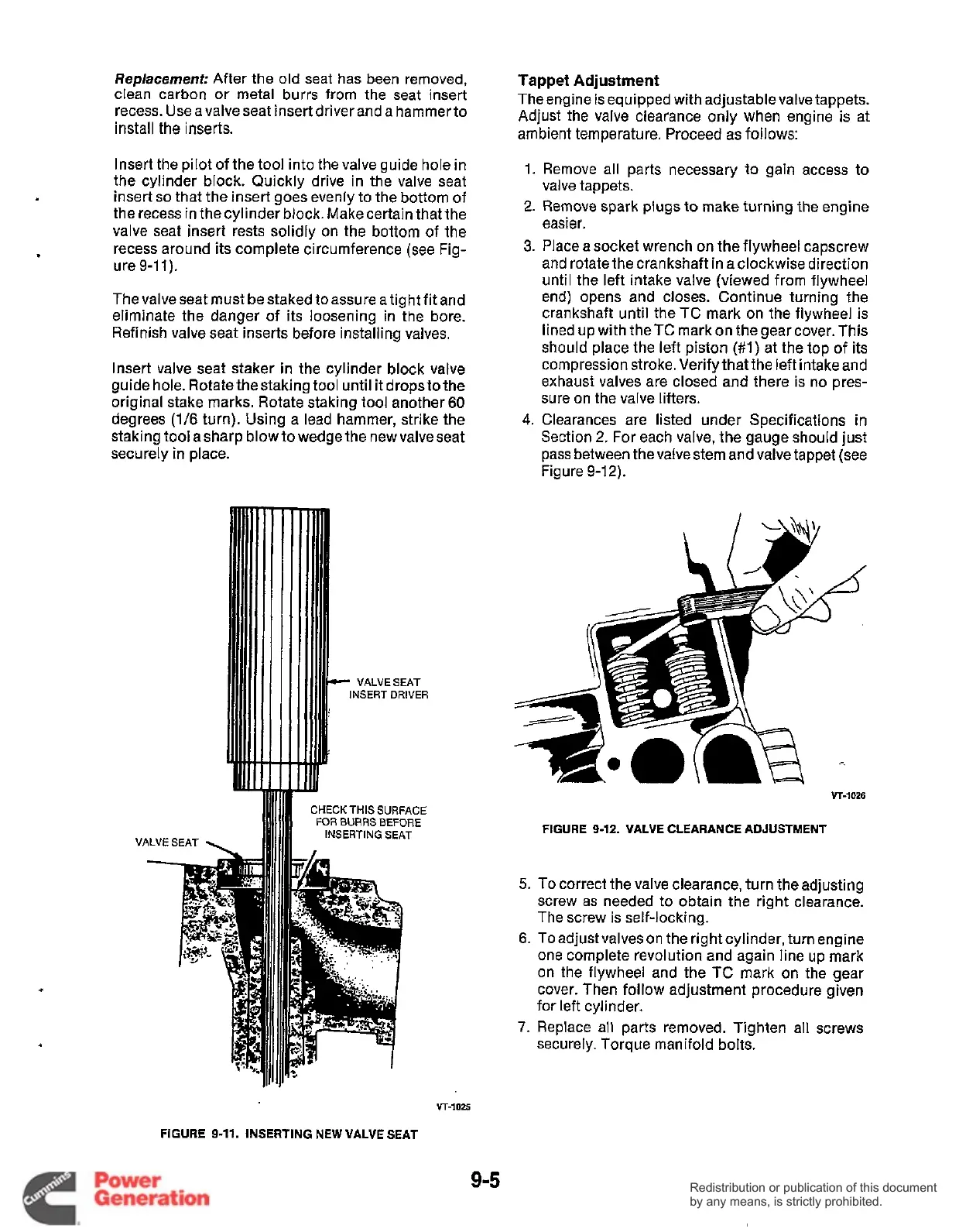

Insert the pilot of the tool into the valve guide hole in

the cylinder block. Quickly drive in the valve seat

insert

so

that the insert goes evenly to the bottom

of

the recess in the cylinder block. Make certain that the

valve seat insert rests solidly on the bottom of the

recess around its complete circumference (see Fig-

ure

9-1

1).

Thevalveseat must bestaked toassureatightfitand

eliminate the danger of its loosening in the bore.

Refinish valve seat inserts before installing valves.

Insert valve seat staker in the cylinder block valve

guide hole. Rotate thestaking tool until

it

dropsto the

original stake marks. Rotate staking tool another

60

degrees

(1/6

turn). Using a lead hammer, strike the

staking tool asharp blow to wedge the new valve seat

securely in place.

Tappet Adjustment

The engine is equipped with adjustable valve tappets.

Adjust the valve clearance only when engine is at

ambient temperature. Proceed as follows:

1.

Remove all parts necessary to gain access to

valve tappets.

2.

Remove spark

plugs

to make turning the engine

easier.

3.

Place a socket wrench

on

the flywheel capscrew

and rotate the crankshaft in aclockwise direction

until the left intake valve (viewed from flywheel

end) opens and closes. Continue turning the

crankshaft until the

TC

mark on the flywheel is

lined up with theTC mark on thegear cover. This

should place the left piston

(#1)

at the top of its

compression stroke. Verify that the left intake and

exhaust valves are closed and there is no pres-

sure on the valve lifters.

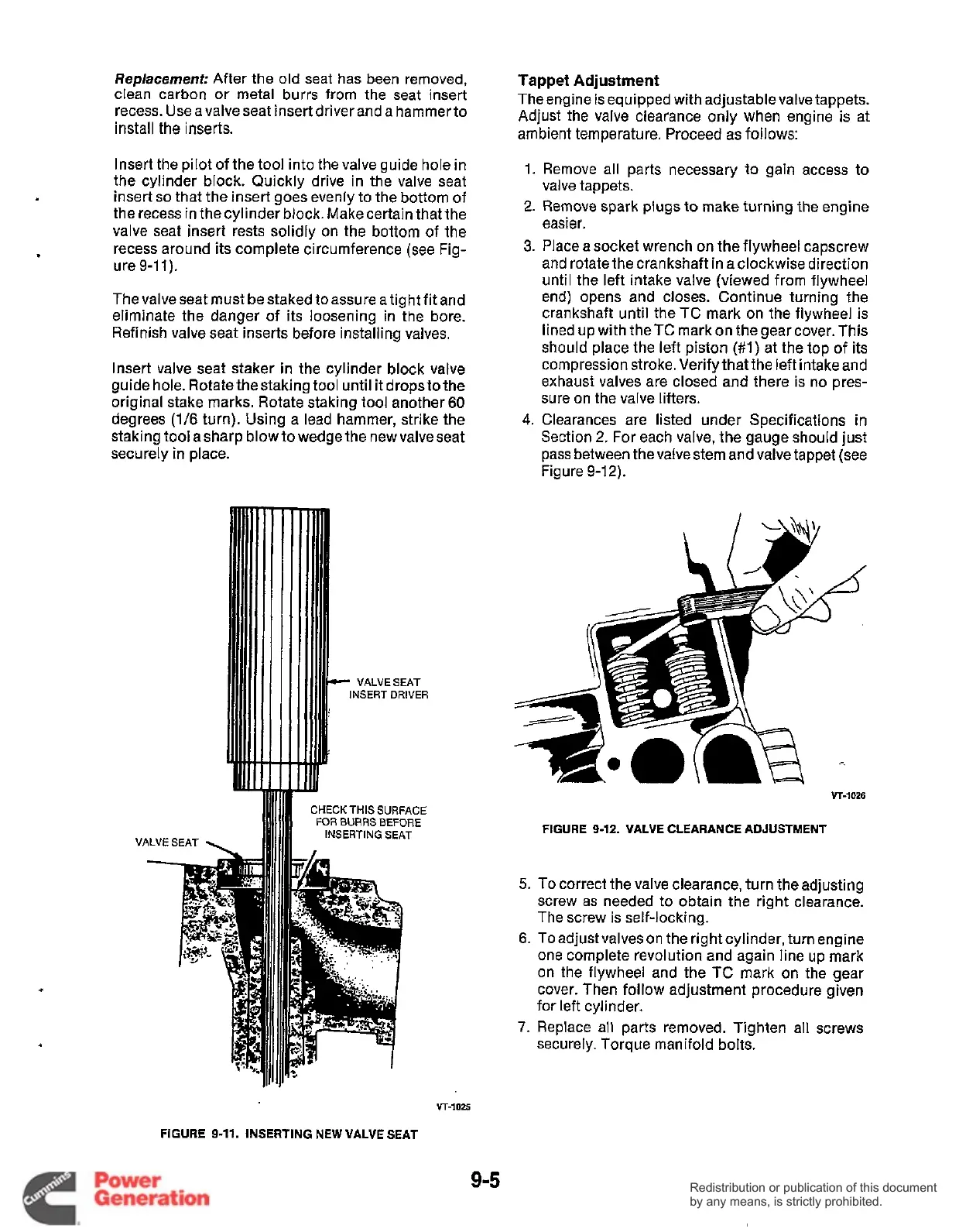

4.

Clearances are listed under Specifications in

Section

2.

For each valve, the gauge should just

pass between the valve stem and valve tappet (see

Figure

9-12).

VT-1026

CHECK

THIS

SURFACE

FOR

BURRS BEFORE

INSERTING

SEAT

FIGURE

9-12.

VALVE CLEARANCE ADJUSTMENT

5.

To correct the valve clearance, turn the adjusting

screw as needed to obtain the right clearance.

The screw is self-locking.

6.

To adjust valves on the right cylinder, turn engine

one complete revolution and again line up mark

on the flywheel and the

TC

mark on the gear

cover. Then follow adjustment procedure given

for left cylinder.

7.

Replace all parts removed. Tighten all screws

securely. Torque manifold bolts.

VT-1025

FIGURE

9-11.

INSERTING NEW VALVE SEAT

9-5

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...