4.

Check the frequency and voltage first with a load

applied and then with no load applied. The fre-

quency and voltage should stay within the limits

shown in Table 6-1.

TABLE

6-1.

VOLTAGE AND SPEED

CHARTS

VOLTAGE CHART

FOR

CHECKING

1

PHASE

Maximum 132

Minimum 108

GOVERNOR

REGULATION

2

WIRE

No-Load Voltage

Full-Load Voltage

SPEED CHART

FOR

CHECKING

GOVERNOR

REGULATION

Maximum No-Load Speed (Rpm) 1890

Hertz (Frequency) 63

Minimum Full-Load Speed 1770

(Rpm) Hertz 57

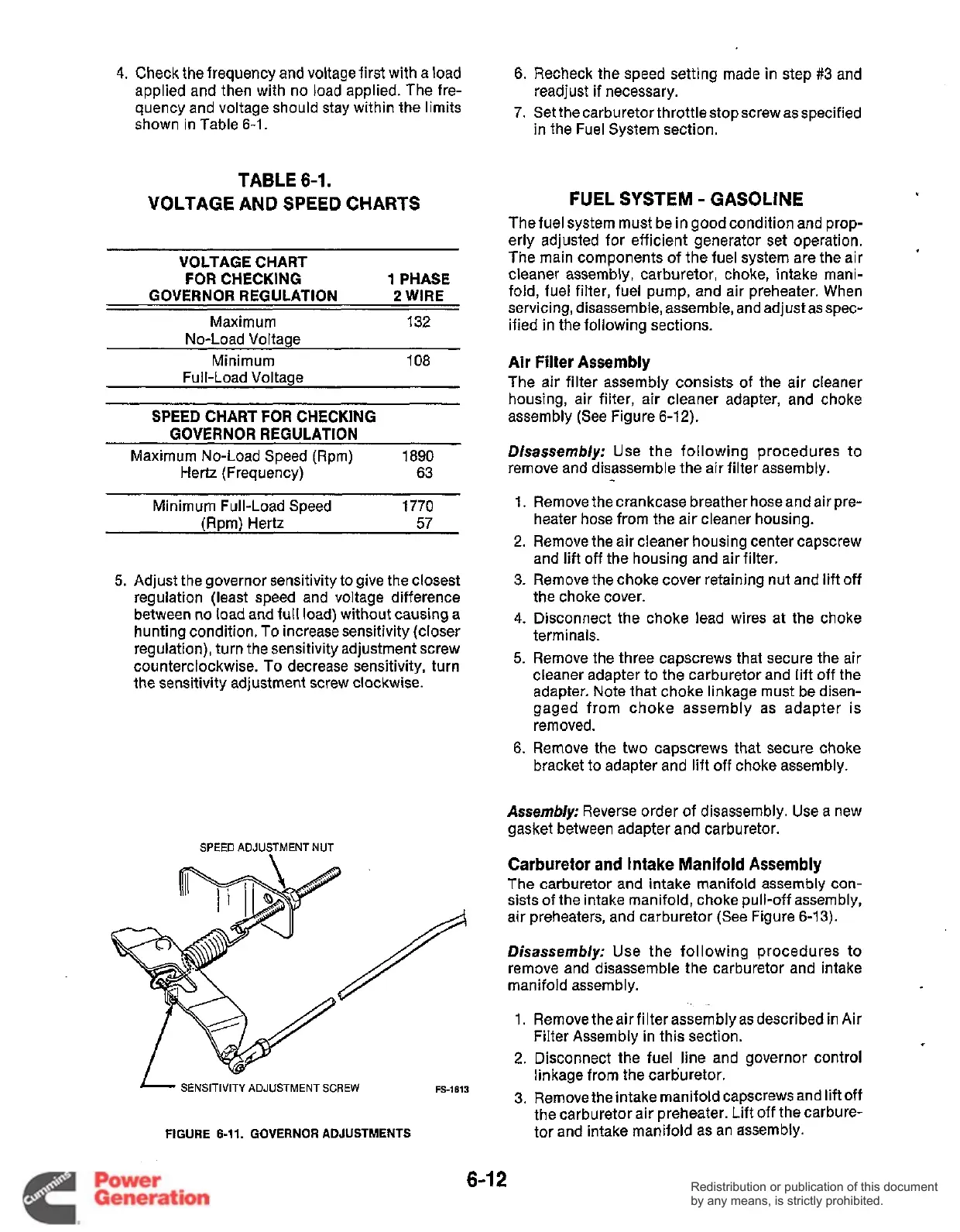

5.

Adjust the governor sensitivity to give the closest

regulation (least speed and voltage difference

between

no

load and full load) without causing a

hunting condition.

To

increase sensitivity (closer

regulation), turn the sensitivity adjustment screw

counterclockwise. To decrease sensitivity, turn

the sensitivity adjustment screw clockwise.

SPEED ADJUSTMENT NUT

-

SENSITIVITY

ADJUSTMENT

SCREW

FS-1613

FIGURE

6-11.

GOVERNOR ADJUSTMENTS

6.

Recheck the speed setting made in step

#3

and

7. Set thecarburetor throttlestop screw as specified

readjust if necessary.

in the Fuel System section.

FUEL

SYSTEM

-

GASOLINE

The fuel system must be in good condition and prop-

erly adjusted for efficient generator set operation.

The main components of the fuel system are the air

cleaner assembly, carburetor, choke, intake mani-

fold, fuel filter, fuel pump, and air preheater. When

servicing, disassemble, assemble, and adjust as spec-

ified in the following sections.

Air Filter Assembly

The air filter assembly consists of the air cleaner

housing, air filter, air cleaner adapter, and choke

assembly (See Figure 6-12).

Disassembly:

Use the following procedures to

remove and disassemble the air filter assembly.

1. Remove the crankcase breather hose and air pre-

heater hose from the air cleaner housing.

2. Remove the air cleaner housing center capscrew

and lift off the housing and air filter.

3. Remove the choke cover retaining nut and lift off

the choke cover.

4.

Disconnect the choke lead wires at the choke

terminals.

5.

Remove the three capscrews that secure the air

cleaner adapter to the carburetor and lift off the

adapter. Note that choke linkage must be disen-

gaged from choke assembly as adapter is

removed.

6. Remove the two capscrews that secure choke

bracket to adapter and lift off choke assembly.

-

Asseddy:

Reverse order of disassembly. Use

a

new

gasket between adapter and carburetor.

Carburetor and Intake Manifold Assembly

The carburetor and intake manifold assembly con-

sists of the intake manifold, choke pull-off assembly,

air preheaters, and carburetor (See Figure 6-13).

Disassembly:

Use the following procedures to

remove and disassemble the carburetor and intake

manifold assembly.

1. Removetheair filterassembly asdescribed in Air

Filter Assembly in this section.

2. Disconnect the fuel line and governor control

linkage from the carburetor.

3. Remove the intake manifold capscrews and lift off

the carburetor air preheater. Lift off the carbure-

tor and intake manifold as an assembly.

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.