3.

To measure resistance in the primary circuit,

connect one ohmmeter lead to the positive

(+)

terminal and the other to the negative

(-)

terminal

on the coil. The resistance should be between

3.87

and

4.73

ohms.

A

high resistance value indi-

cates an open circuit or poor connection inside

the coil, and the coil should be replaced.

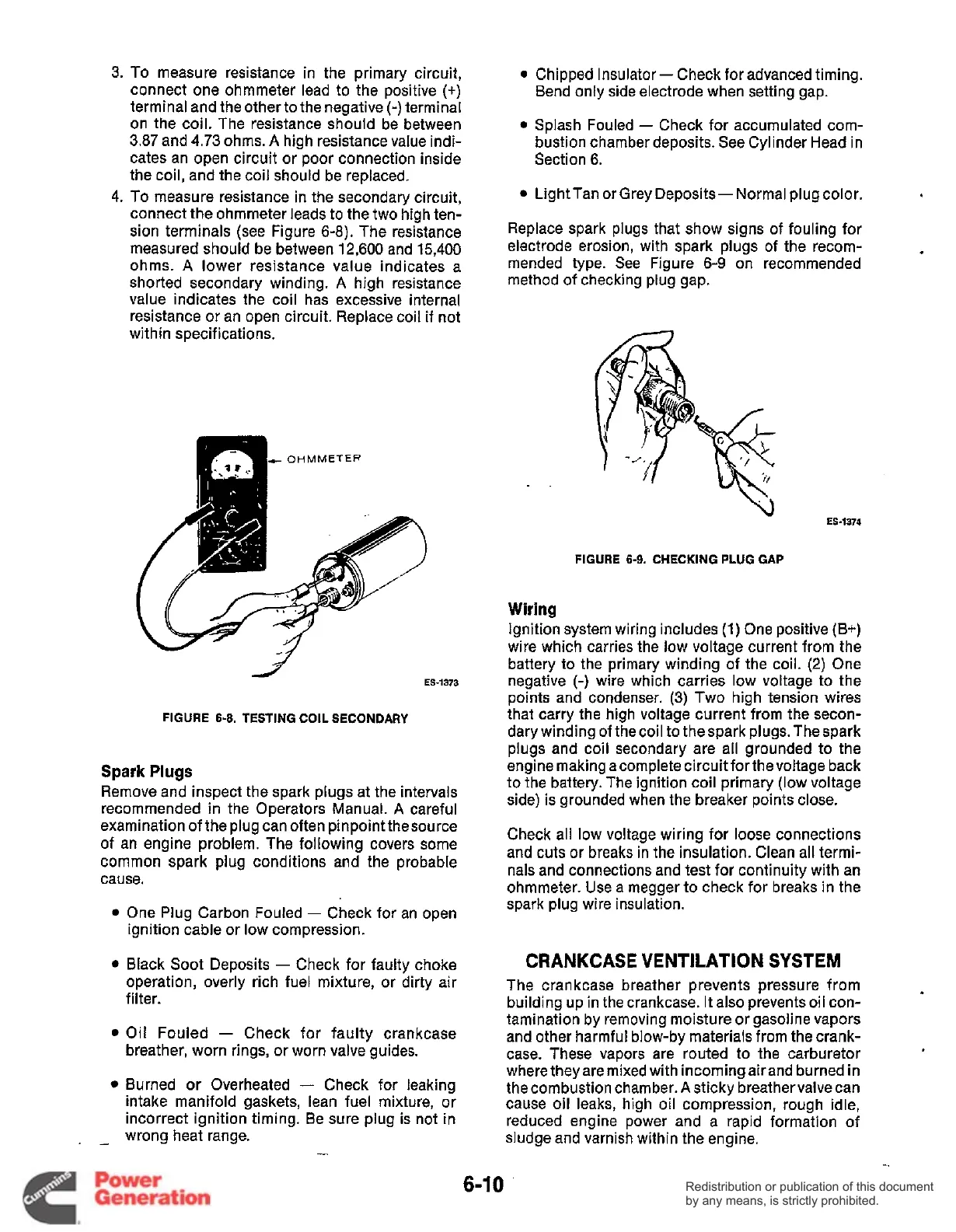

4.

To

measure resistance in the secondary circuit,

connect the ohmmeter leads to the two high ten-

sion terminals (see Figure

6-8).

The resistance

measured should be between

12,600

and 15,400

ohms.

A

lower resistance value indicates a

shorted secondary winding.

A

high resistance

value indicates the coil has excessive internal

resistance or an open circuit. Replace coil if not

within specifications.

-

OHMMETER

-

OHMMETER

Chipped Insulator

-

Check for advanced timing.

Bend only side electrode when setting gap.

Splash Fouled

-

Check for accumulated com-

bustion chamber deposits. See Cylinder Head in

Section

6.

LightTan or Grey Deposits- Normal plug color.

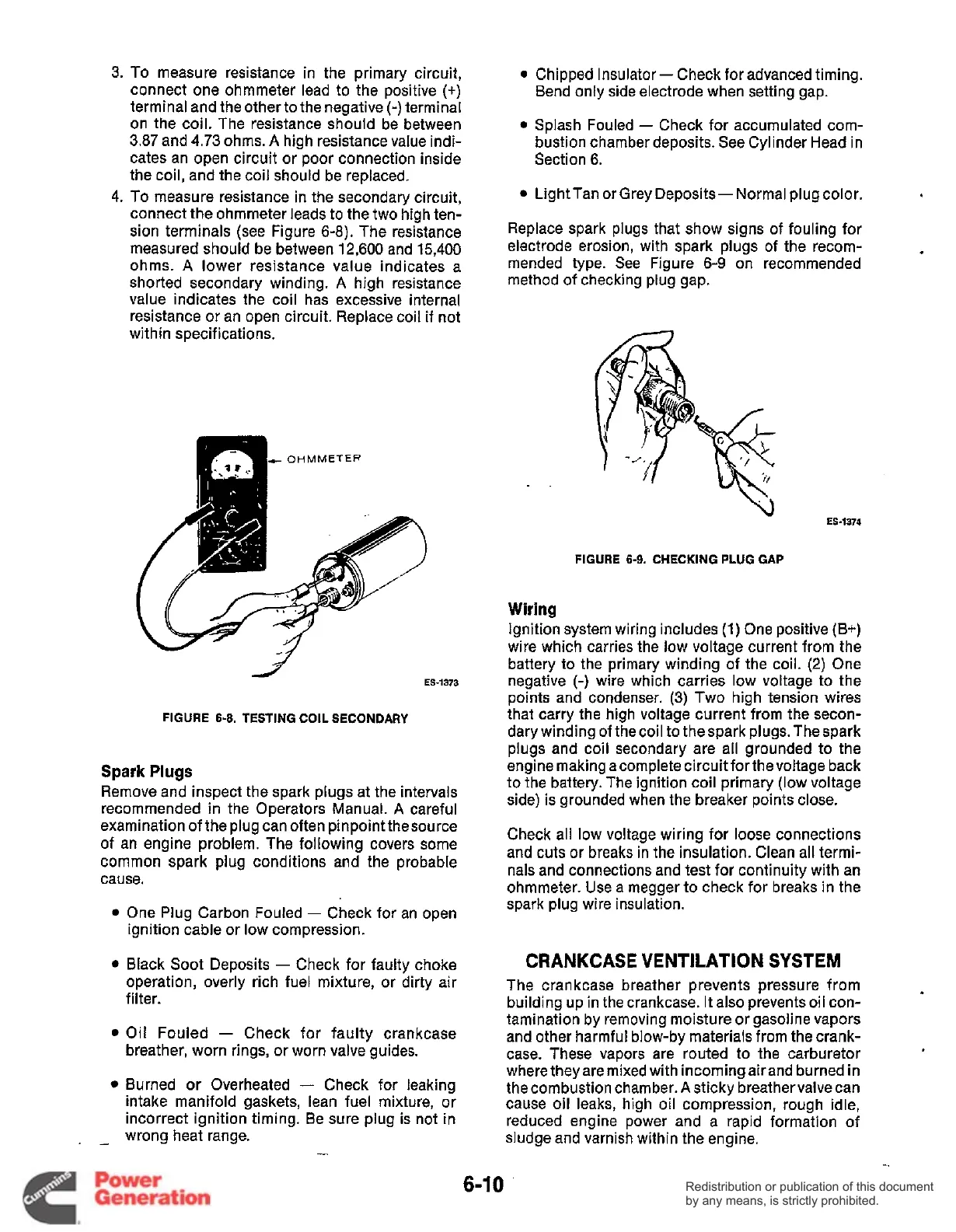

Replace spark plugs that show signs of fouling for

electrode erosion, with spark plugs of the recom-

mended type. See Figure

6-9

on

recommended

method of checking plug gap.

ES-1374

FIGURE

6-9.

CHECKING PLUG GAP

Wiring

Ignition system wiring includes (1) One positive

(e+)

wire which carries the low voltage current from the

battery to the primary winding of the coil.

(2)

One

negative

(-)

wire which carries low voltage to the

points and condenser.

(3)

Two high tension wires

that carry the high voltage current from the secon-

dary winding of the coil to the spark plugs. The spark

plugs and coil secondary are all grounded to the

ES-1373

FIGURE

6-8.

TESTING COIL SECONDARY

enghe making a completecircuit foFthevoltage back

to the battery. The ignition coil primary (low voltage

Spark

Plugs

recommended in the Operators Manual.

A

careful

Remove

and

inspect

the

spark Plugs

at

the

intervals

side) is grounded when the breaker points close.

examination of the plug can often pinpointthesource

of an engine problem. The following covers some

common

spark

plug

conditions

and

the

probable

cause.

One Plug Carbon Fouled

-

Check for an open

Check

all

low

voltage

wiring

for

loose

connections

and cuts or breaks in the insulation. Clean all termi-

nals and connections and test for continuity with an

ohmmeter. Use a megger

to

check for breaks in the

spark plug wire insulation.

ignition cable or low compression.

Black Soot Deposits

-

Check for faulty choke

operation, overly rich fuel mixture, or dirty air

filter.

Oil Fouled

-

Check for faulty crankcase

breather, worn rings, or worn valve guides.

Burned or Overheated

-

Check for leaking

intake manifold gaskets, lean fuel mixture, or

incorrect ignition timing. Be sure plug is not in

-

wrong heat range.

CRANKCASE VENTILATION SYSTEM

The crankcase breather prevents pressure from

building up in the crankcase. It also prevents oil con-

tamination by removing moisture or gasoline vapors

and other harmful blow-by materials from the crank-

case. These vapors are routed to the carburetor

where they are mixed with incoming airand burned in

the combustion chamber.

A

sticky breather valve can

cause oil leaks, high oil compression, rough idle,

reduced engine power and a rapid formation of

sludge and varnish within the engine.

6-1

0

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...