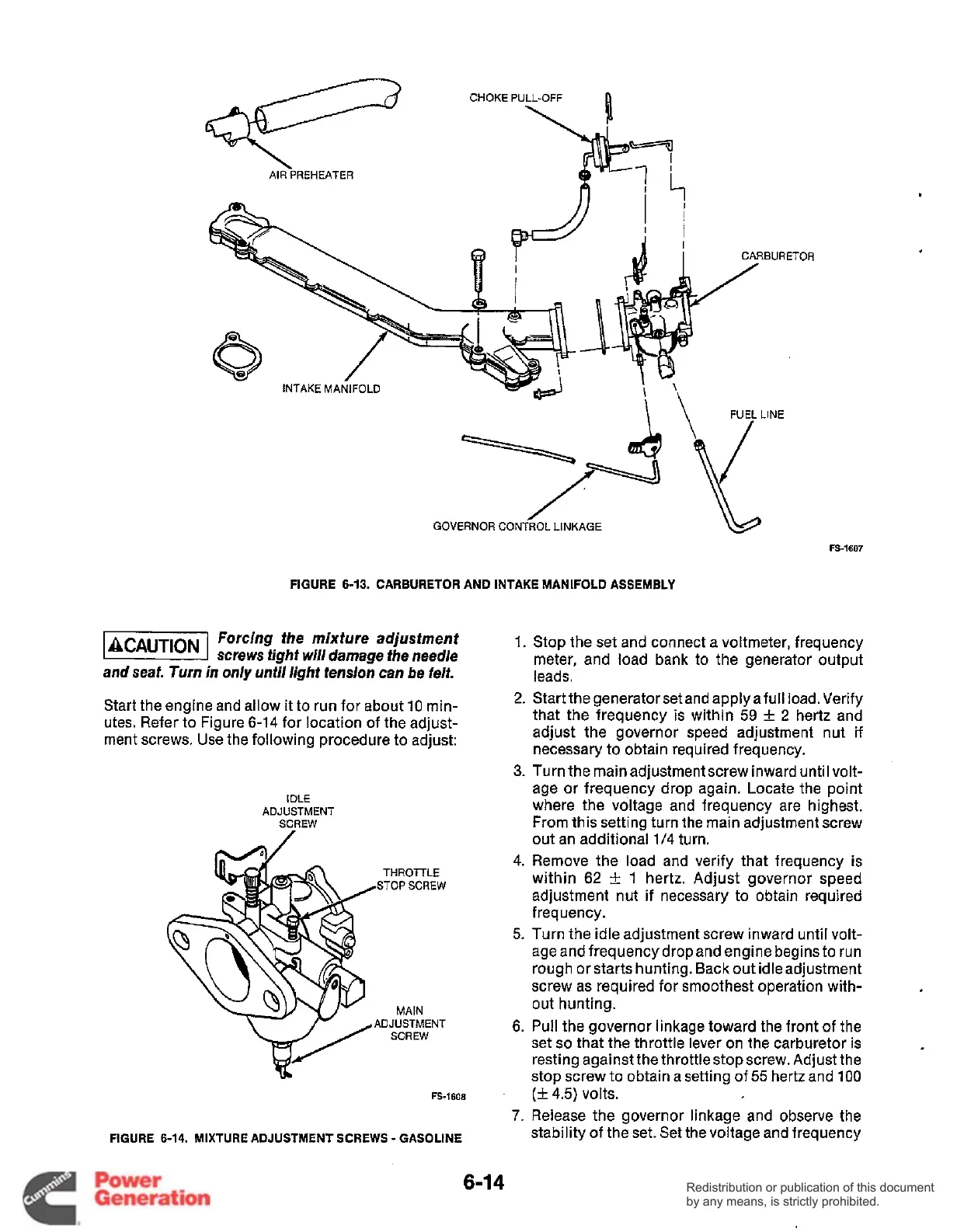

CHOKE PULL-OFF

n

AIR~PREHEATER

db-1

\\\

\

91

i

INTAKE MANIFOLD

\\

FUEL LINE

\,a

‘1

GOVERNOR CONTROL LINKAGE

FS-1607

FIGURE 6-13.

CARBURETOR

AND

INTAKE

MANIFOLD

ASSEMBLY

Forcing the mixture adjustment

@%&%I

screws fight

wi//

damage the needle

and seat. Turn in only

until

light tension can be felt.

1.

Stop the set and connect a voltmeter, frequency

meter, and load bank to the generator output

leads.

2.

Start the generator set and applyafull load. Verify

that the frequency

is

within

59

k

2

hertz and

adjust the governor speed adjustment nut if

necessary to obtain required frequency.

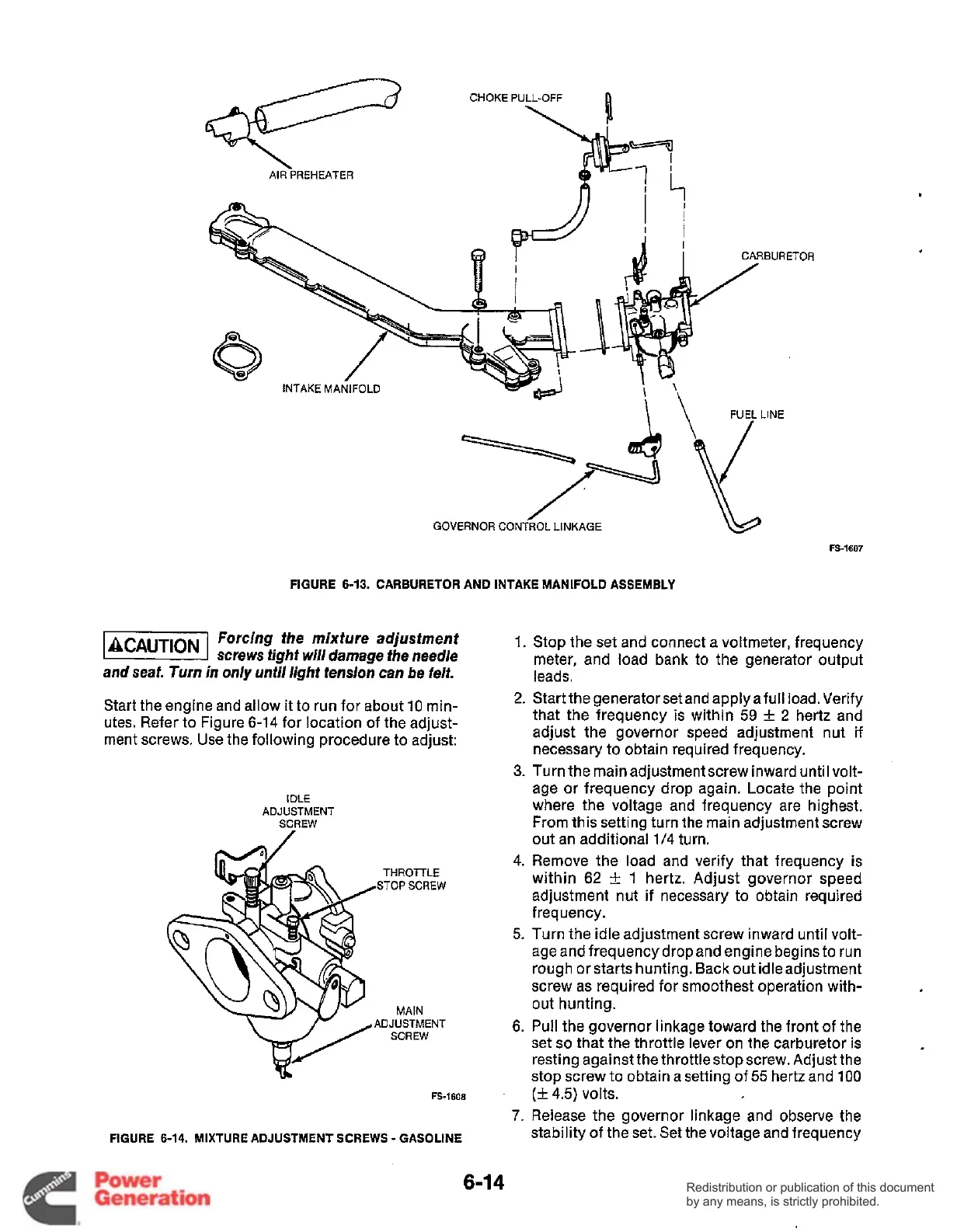

Start the engine and allow it to run for about 10 min-

Utes. Refer to Figure 6-14 for location of the adjust-

ment screws. Use the following procedure to adjust:

3.

Turn the main adjustment screw inward until volt-

age or frequency drop again. Locate the point

where the voltage and frequency are highest.

From this setting turn the main adjustment screw

out an additional 1/4 turn.

4. Remove the load and verify that frequency is

within

62

k

1

hertz. Adjust governor speed

adjustment nut if necessary to obtain required

frequency.

5.

Turn the idle adjustment screw inward until volt-

age and frequency dropand engine begins to run

rough or starts hunting. Back out idle adjustment

screw as required for smoothest operation with-

6.

Pull the governor linkage toward the front of the

set

so

that the throttle lever on the carburetor is

resting against the throttle stop screw. Adjust the

stop screw to obtain a setting

of

55

hertz and 100

7.

Release the governor linkage and observe the

stability

of

the set. Set the voltage and frequency

IDLE

ADJUSTMENT

SCREW

THROTTLE

STOP

SCREW

MAIN

out hunting.

ADJUSTMENT

SCREW

FS-1608

(k

4.5) volts.

FIGURE

6-14.

MIXTURE

ADJUSTMENT

SCREWS

-

GASOLINE

6-1

4

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...