PISTON

ASSEMBLY

The piston assembly consists of the piston, piston

rings, piston pin, connecting rod assembly, and bear-

ing. After removal from the engine, all parts must be

carefully inspected for damage and wear before

replacing.

Removal and Disassembly

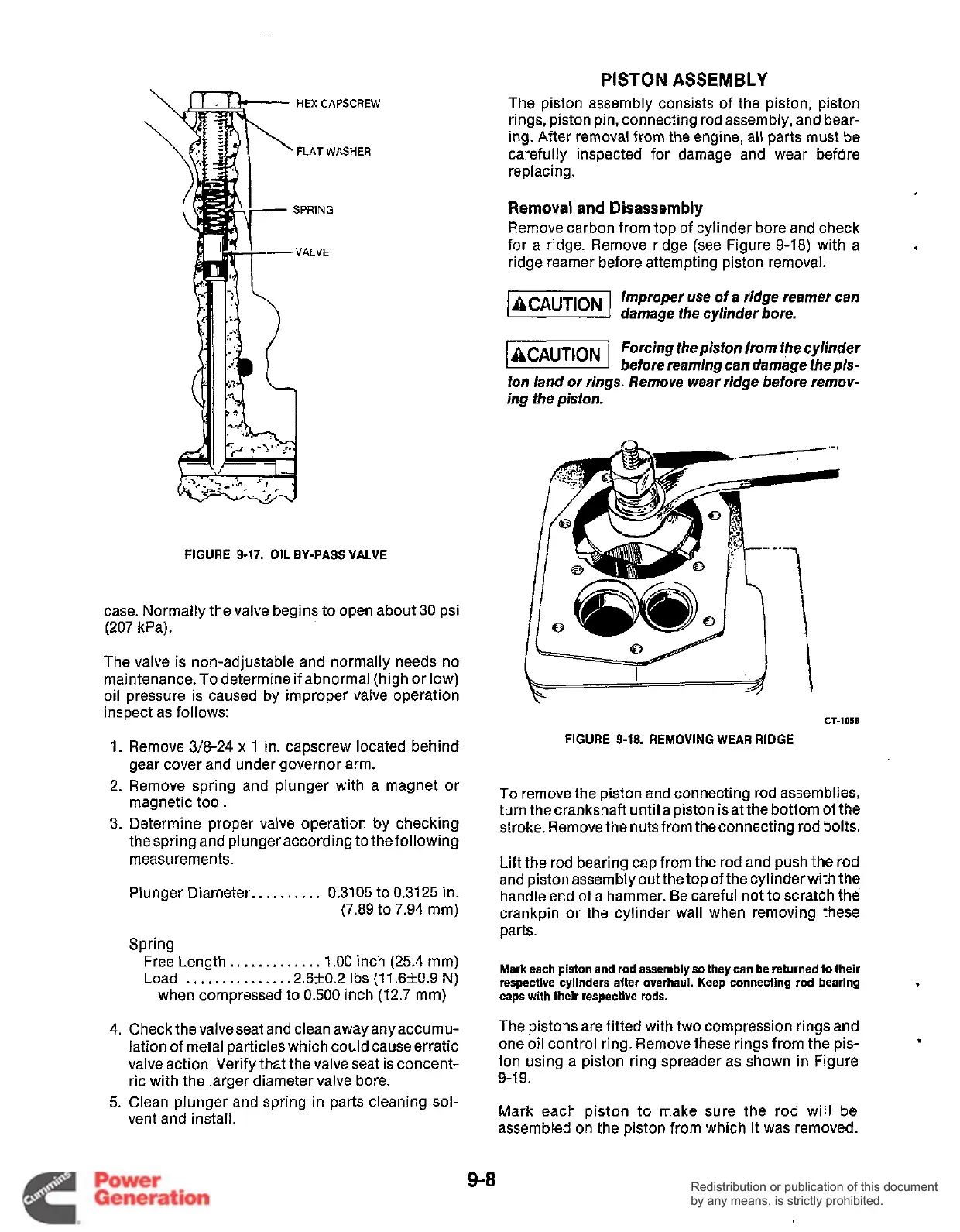

Remove carbon from top of cylinder bore and check

for a ridge. Remove ridge (see Figure

9-18)

with a

ridge reamer before attempting piston removal.

Improper

use

of a ridge reamer can

damage

fhe

cylinder bore.

1-1

Forcing the piston from

fhe

cylinder

before reaming can damage fhe pis-

ton land or rings. Remove wear ridge before remov-

ing the piston.

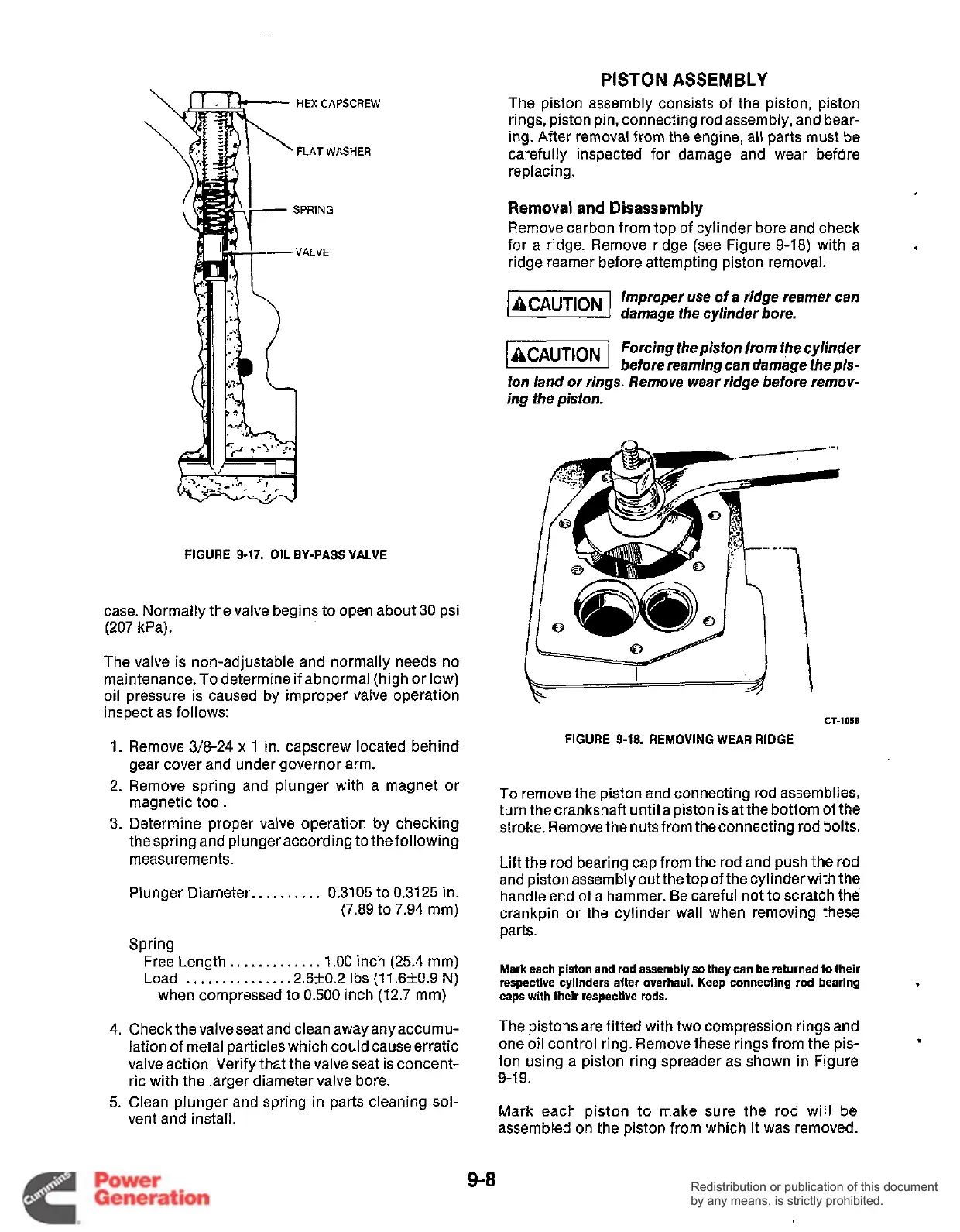

HEX

CAPSCREW

FLAT

WASHER

FIGURE

9-17.

OIL BY-PASS VALVE

CT-1058

case. Normally the valve begins to open about 30 psi

(207

kPa).

The valve is non-adjustable and normally needs

no

maintenance.To determine if abnormal (high or low)

oil pressure is caused by improper valve operation

inspect as follows:

1.

2.

3.

4.

5.

Remove

3/8-24

x

1

in. capscrew located behind

gear cover and under governor arm.

Remove spring and plunger with a magnet or

magnetic tool.

Determine proper valve operation

by

checking

thespring and plungeraccording to the following

measurements.

Plunger Diameter..

,

.

.

.

.

.

.

.

0.3105 to 0.3125 in.

(7.89 to

7.94

mm)

Spring

Free Length.,

. .

.

.

. . .

.

.

.

.

1.00

inch (25.4 mm)

Load

.

,

.

.

,

.

.. .

..

.

. .

.2.6-+0.2 Ibs

(11.6f0.9

N)

when compressed to

0.500

inch (12.7 mm)

Check the valveseat and clean away anyaccumu-

lation of metal particles which could causeerratic

valve action. Verify that the valve seat is concent-

ric with the larger diameter valve bore.

Clean plunger and spring in parts cleaning sol-

vent and install.

FIGURE

9-18.

REMOVING WEAR RIDGE

To

remove the piston and connecting rod assemblies,

turn the crankshaft until a piston is at the bottom of the

stroke. Remove the nuts from theconnecting rod bolts.

Lift the rod bearing cap from the rod and push the rod

and piston assembly out the top of the cylinder with the

handle end of a hammer. Be careful not to scratch the

crankpin or the cylinder wall when removing these

parts.

Mark each piston and rod assembly

so

they can be returned to their

respective cylinders after overhaul. Keep connecting rod bearing

caps with their respective rods.

The pistons are fitted with two compression rings and

one oil control ring. Remove these rings from the pis-

ton using a piston ring spreader as shown in Figure

9-1

9.

.

Mark each piston

to

make sure the rod will be

assembled on the piston from which it was removed.

9-8

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...