1.

Slide in throttle shaft and install throttle plate

using new screws, if furnished in repair kit. Before

tightening the screws, the plate must be centered

in the bore.

To

do

so,

back off the throttle stop

screw as necessary and completely close the

throttle lever. Seat the plate by gently tapping

with a small screwdriver, then tighten screws.

Install the choke shaft and plate in the same

manner.

FS-1483

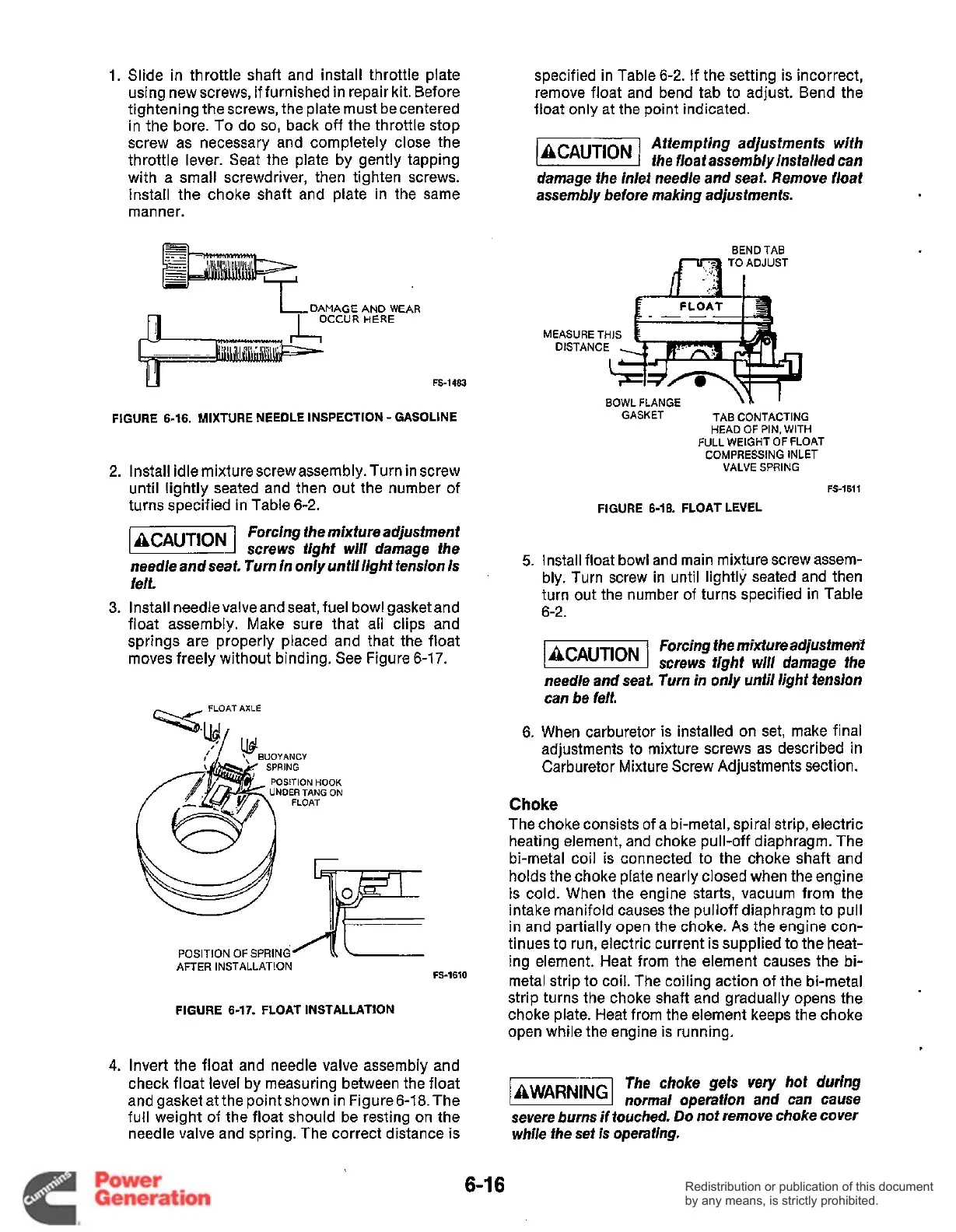

FIGURE 6-16.

MIXTURE

NEEDLE INSPECTION

-

GASOLINE

Install idle mixture screw assembly. Turn in screw

until lightly seated and then out the number of

turns specified in Table 6-2.

Forcing the mixture adjustmenf

screws tight will damage the

needle and seat Turn in only untillight tension

is

felt.

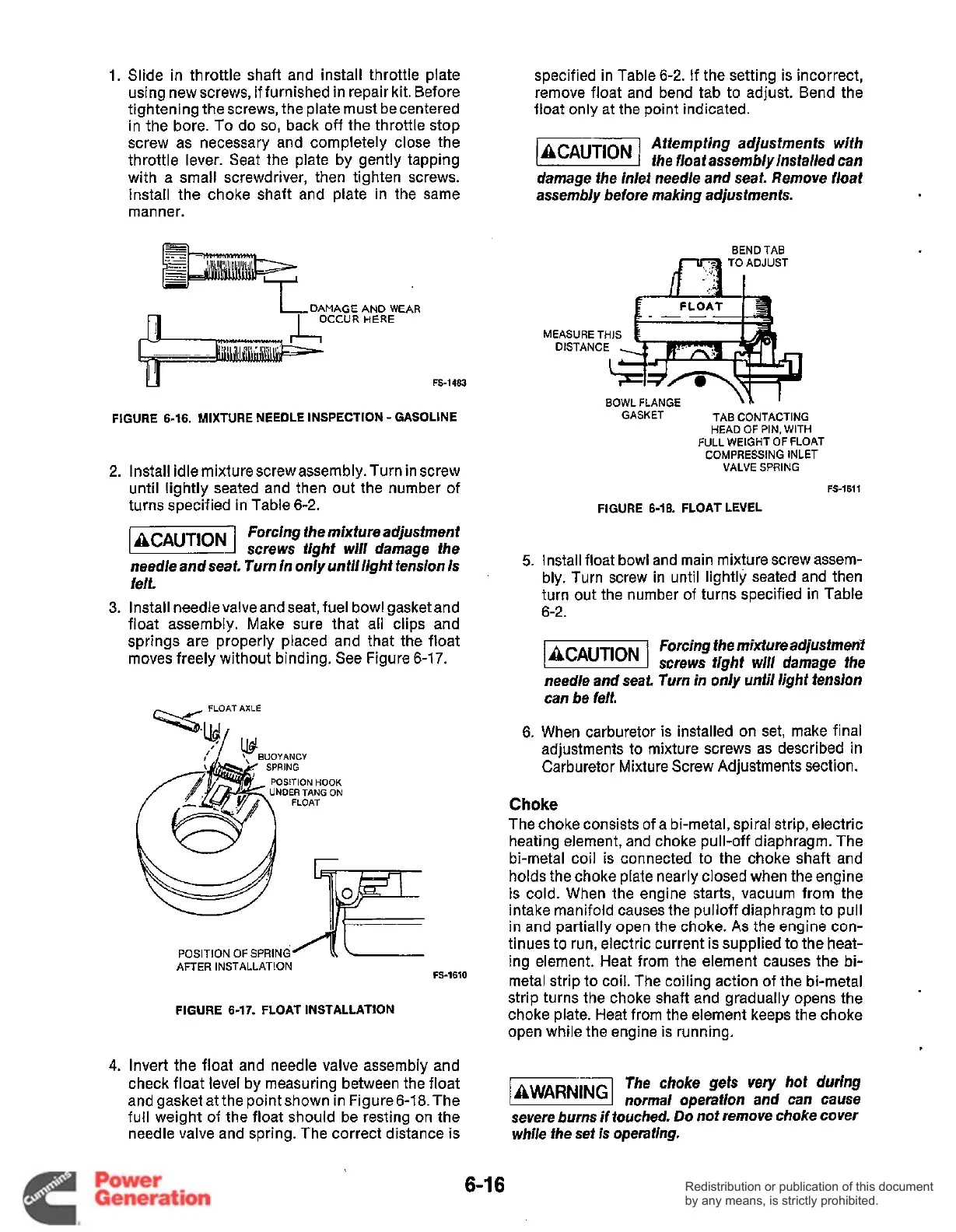

Install needle valveand seat, fuel bowl gasket and

float assembly. Make sure that all clips and

springs are properly placed and that the float

moves freely without binding. See Figure 6-17.

POSITION

HOOK

NDER TANG ON

FS-1610

POSITION OF SPRING

,AL

AFTER INSTALLATION

FIGURE 6-17. FLOAT INSTALLATION

Invert the float and needle valve assembly and

check float level by measuring between the float

and gasket at the point shown in Figure 6-18.The

full weight of the float should be resting on the

needle valve and spring. The correct distance is

specified in Table 6-2. If the setting is incorrect,

remove float and bend tab to adjust. Bend the

float only at the point indicated.

Attempting adjustments with

k&%!!@l

the

floaf

assembly installed can

damage the inlet need/e and seat. Remove float

assembly before making adjustments.

BEND TAB

*I+--

BOWL FLANGE

\L

'

TAB CONTACTING

HEAD

OF

PIN, WITH

FULL WEIGHT OF FLOAT

COMPRESSING INLET

VALVE SPRING

GASKET

FS-1611

FIGURE 6-18. FLOAT LEVEL

Install float bowl and main mixture screw assem-

bly. Turn screw in until lightly seated and then

turn out the number of turns specified in Table

6-2.

Forcing the mixture adjustmefit

screws tight will damage the

needle and seat. Turn in only until light tension

can be felt.

When carburetor is installed on set, make final

adjustments to mixture screws as described in

Carburetor Mixture Screw Adjustments section.

Choke

The choke consists of a bi-metal, spiral strip, electric

heating element, and choke pull-off diaphragm. The

bi-metal coil is connected to the choke shaft and

holds the choke plate nearly closed when the engine

is cold. When the engine starts, vacuum from the

intake manifold causes the pulloff diaphragm to pull

in and partially open the choke.

As

the engine con-

tinues to run, electric current is supplied to the heat-

ing element. Heat from the element causes the bi-

metal strip to coil. The coiling action of the bi-metal

strip turns the choke shaft and gradually opens the

choke plate. Heat from the element keeps the choke

open while the engine is running.

t

The choke gets

very

hot during

normal operation and can cause

severe burns if touched.

Do

nof remove choke cover

while fhe set is operating.

6-1

6

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...