excessively worn and must be replaced. Always

replace the brush springs when installing new

brushes to insure that proper tension is maintained.

Use the following procedure to replace the brushes.

1.

Disconnect the negative

(-)

battery cable at the

battery terminal.

2.

Remove theair cleanercoverand air cleanerfilter

element.

3.

Disconnect the Bt (outboard) and

B-

(inboard)

lead wires from the brush block terminals.

4.

Remove the brush block mounting screws and lift

out the brush block.

5.

Remove brushes and brush springs from holder

and replace with new parts.

6.

Pull

each brush outward from the brush holder

and at the same

time

insert (see Figure

8-11)

a

stiff wire through thesmall holes in the base of the

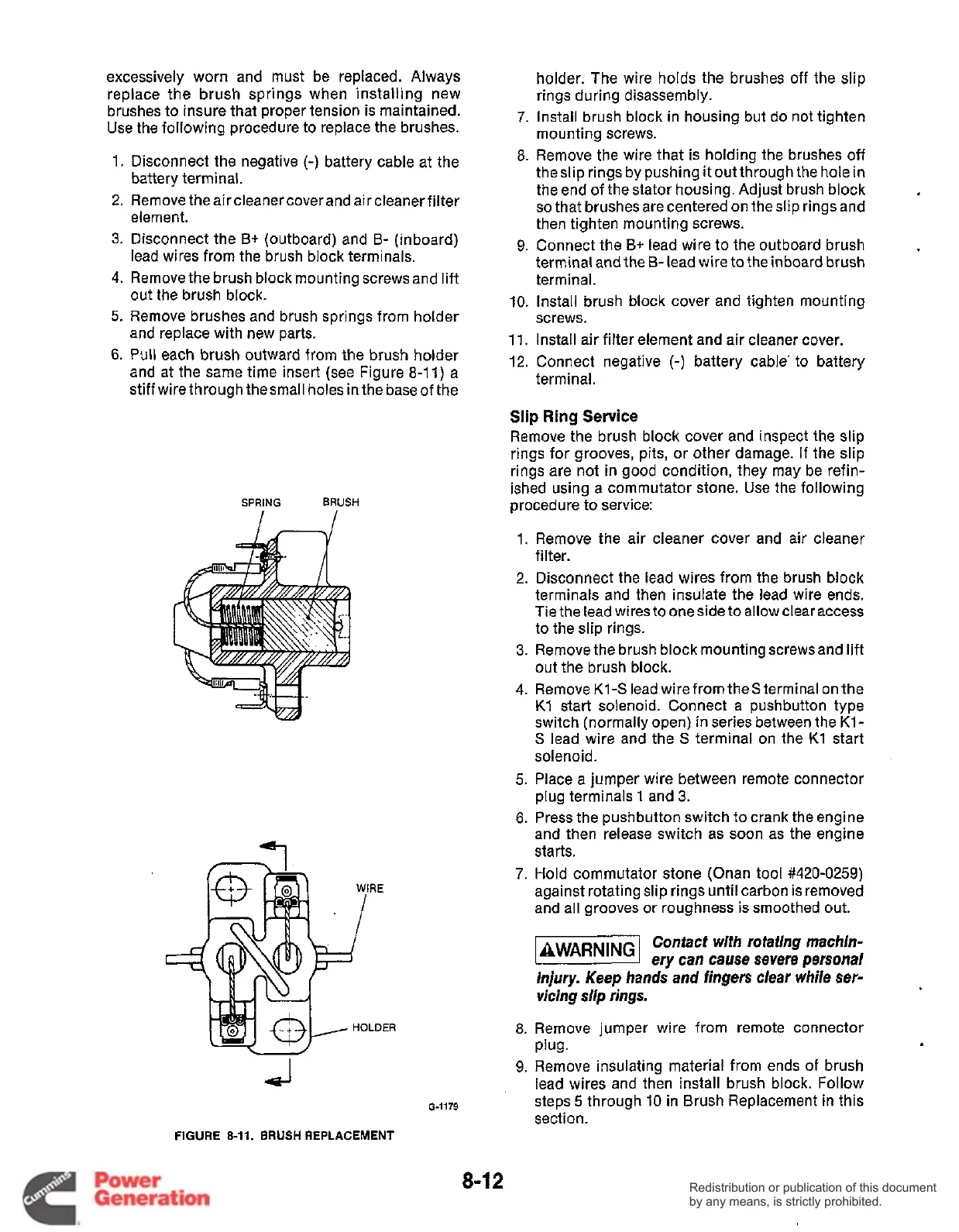

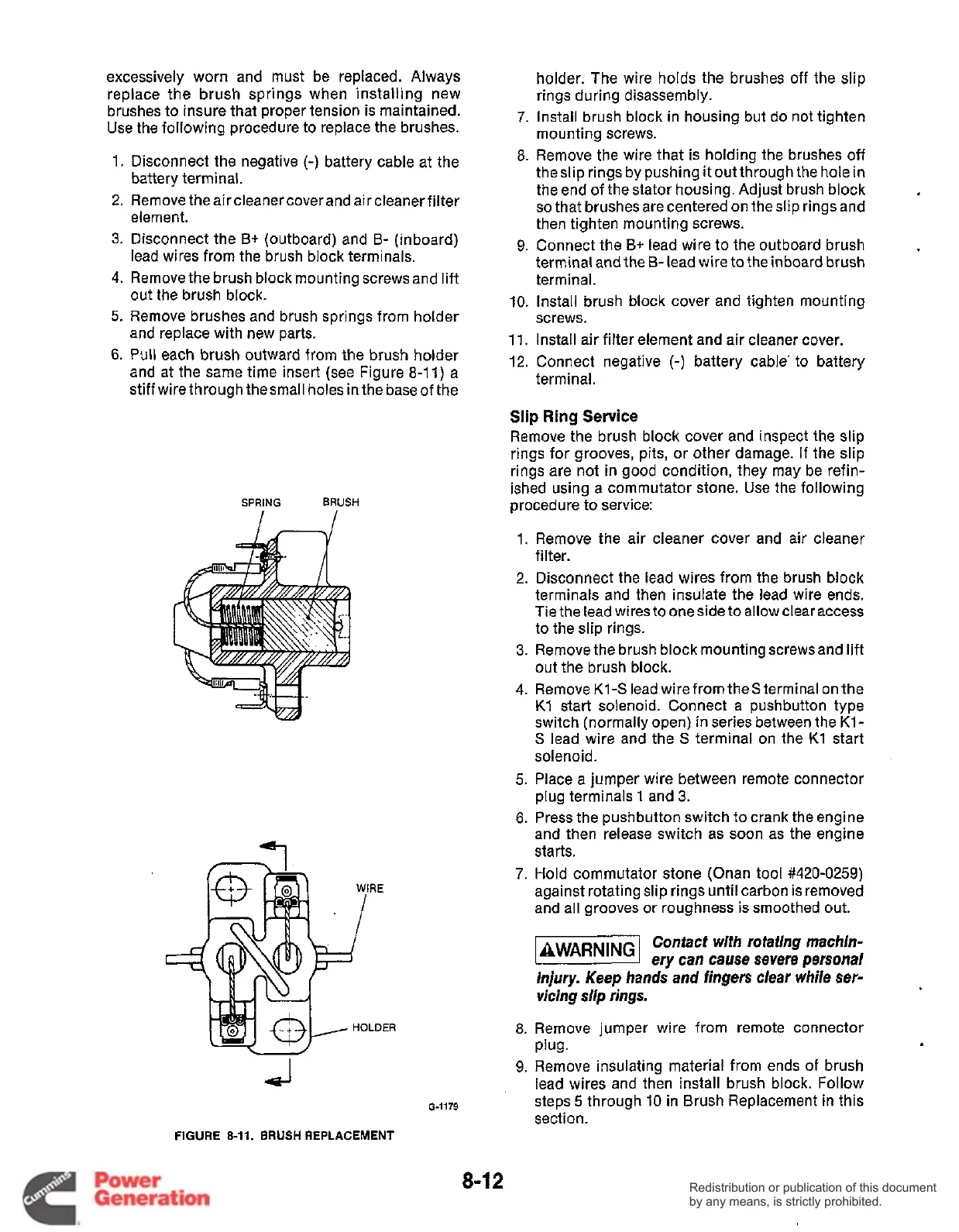

SPRING

BRUSH

G-1179

4-J

FIGURE

8-11.

BRUSH

REPLACEMENT

7.

8.

9.

10.

11.

12.

holder. The wire holds the brushes off the slip

rings during disassembly.

Install brush block in housing but do not tighten

mounting screws.

Remove the wire that is holding the brushes off

the slip rings by pushing

it

out through the hole in

the end of the stator housing. Adjust brush block

so

that brushes are centered on the slip rings and

then tighten mounting screws.

Connect the B+ lead wire to the outboard brush

terminal and the B- lead wire to the inboard brush

terminal.

Install brush block cover and tighten mounting

screws.

Install air filter element and air cleaner cover.

Connect negative

(-)

battery cable' to battery

terminal.

Slip

Ring Service

Remove the brush block cover and inspect the slip

rings for grooves, pits, or other damage.

If

the slip

rings are not in good condition, they may be refin-

ished using a commutator stone. Use the following

procedure to service:

1.

2.

3.

4.

5.

6.

7.

8.

9.

Remove the air cleaner cover and air cleaner

filter.

Disconnect the lead wires from the brush block

terminals and then insulate the lead wire ends.

Tie the lead wires

to

one side to allow clear access

to the slip rings.

Remove the brush block mounting screws and lift

out the brush block.

Remove

K1-S

lead wirefrom theS terminal on the

K1

start solenoid. Connect a pushbutton type

switch (normally open) in series between the

K1-

S

lead wire and the

S

terminal on the

K1

start

solenoid.

Place a jumper wire between remote connector

plug terminals

1

and

3.

Press the pushbutton switch to crank the engine

and then release switch as soon as the engine

starts.

Hold commutator stone (Onan

tool

#420-0259)

against rotating slip rings until carbon is removed

and all grooves or roughness is smoothed out.

Contact

wifh

rotating machin-

IliEEEl

ery can cause severe personal

injury. Keep

hands

and fingers clear while ser-

vicing slip rings.

Remove jumper wire from remote connector

Plug.

Remove insulating material from ends of brush

lead wires and then install brush block. Follow

steps

5

through

10

in Brush Replacement in this

section.

8-1

2

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...