\

-

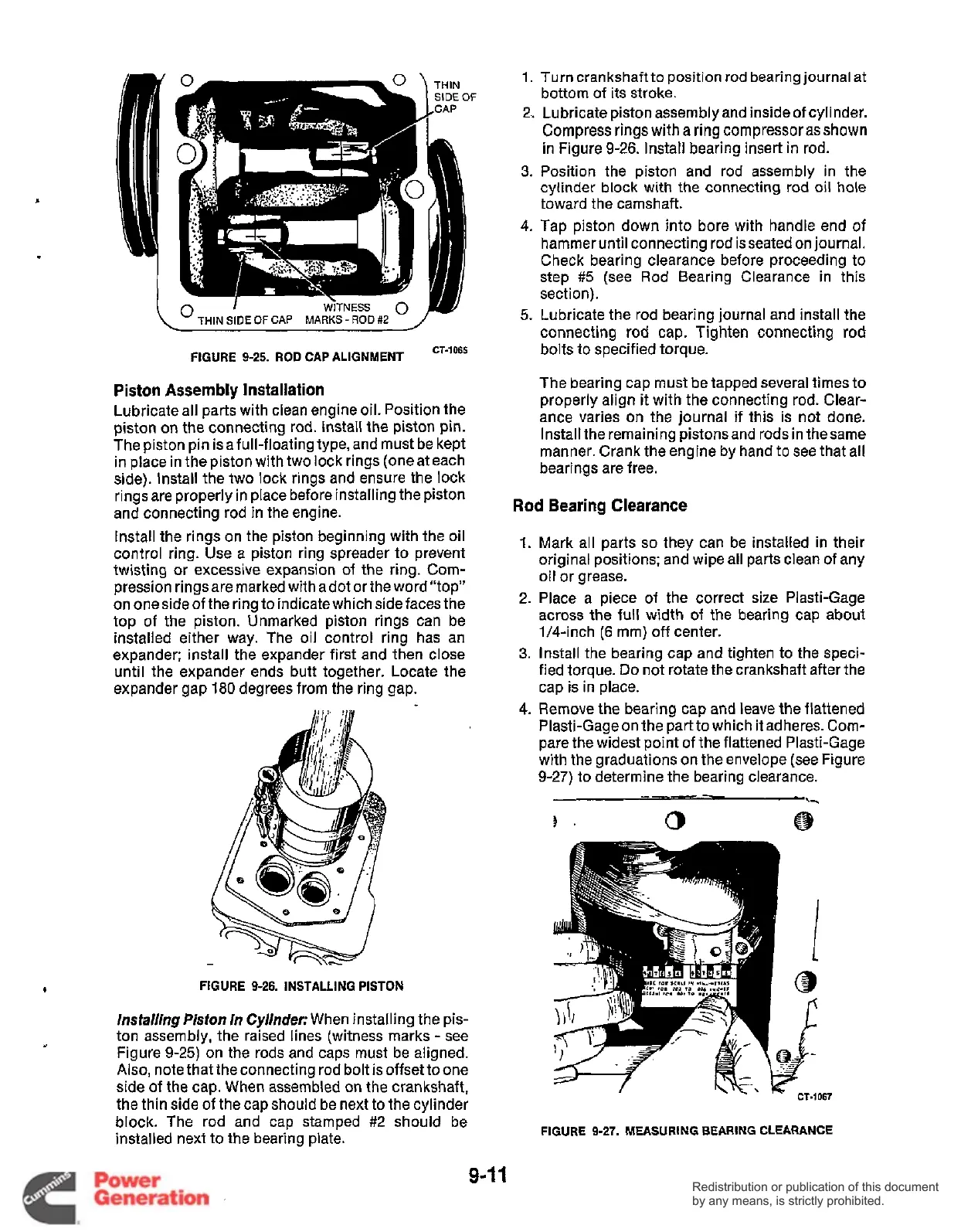

THIN

SIDEOFCAP

MARKS-ROD#2

-

1

-

FIGURE

9-25.

ROD

CAP ALIGNMENT

cT-1065

Piston

Assembly

Installation

Lubricate all parts with clean engine oil. Position the

piston on the connecting rod. Install the piston pin.

The piston pin isa full-floating type, and must be kept

in place in the piston with two lock rings (one at each

side). Install the two lock rings and ensure the lock

rings are properly in place before installing the piston

and connecting rod in the engine.

Install the rings on the piston beginning with the oil

control ring. Use a piston ring spreader to prevent

twisting or excessive expansion of the ring. Com-

pression rings are marked with a dot or the word “top”

on oneside of the ring to indicate which side faces the

top of the piston. Unmarked piston rings can be

installed either way. The oil control ring has an

expander: install the expander first and then close

until the expander ends butt together. Locate the

expander gap

180

degrees from the ring gap.

FIGURE

9-26.

INSTALLING

PISTON

lnsfalling

Piston

in

Cy/indec

When installing the pis-

ton assembly, the raised lines (witness marks

-

see

Figure 9-25) on the rods and caps must be aligned.

Also,

note that the connecting rod bolt is offset to one

side of the cap. When assembled on the crankshaft,

the thin side of the cap should be next to the cylinder

block. The rod and cap stamped #2 should be

installed next to the bearing plate.

1.

Turn

crankshaft to position

rod

bearing journal

at

bottom of its stroke.

2.

Lubricate piston assembly and inside of cylinder.

Compress rings with

a

ring compressor

as

shown

in

Figure

9-26.

install bearing insert in rod.

3.

Position the piston and rod assembly in the

cylinder block with the connecting rod oil hole

toward the camshaft.

4.

Tap piston down into bore with handle end of

hammer until connecting rod isseated on journal.

Check bearing clearance before proceeding to

step

#5

(see Rod Bearing Clearance in this

section).

5.

Lubricate the rod bearing journal and install the

connecting rod cap. Tighten connecting

rod

bolts to specified torque.

The bearing cap must be tapped several times to

properly align

it

with the connecting rod. Clear-

ance varies on the journal if this is not done.

Install the remaining pistonsand rods in thesame

manner. Crank the engine by hand to see that all

bearings are free.

Rod

Bearing Clearance

1.

Mark all parts

so

they can be installed in their

original positions; and wipe all parts clean of any

oil or grease.

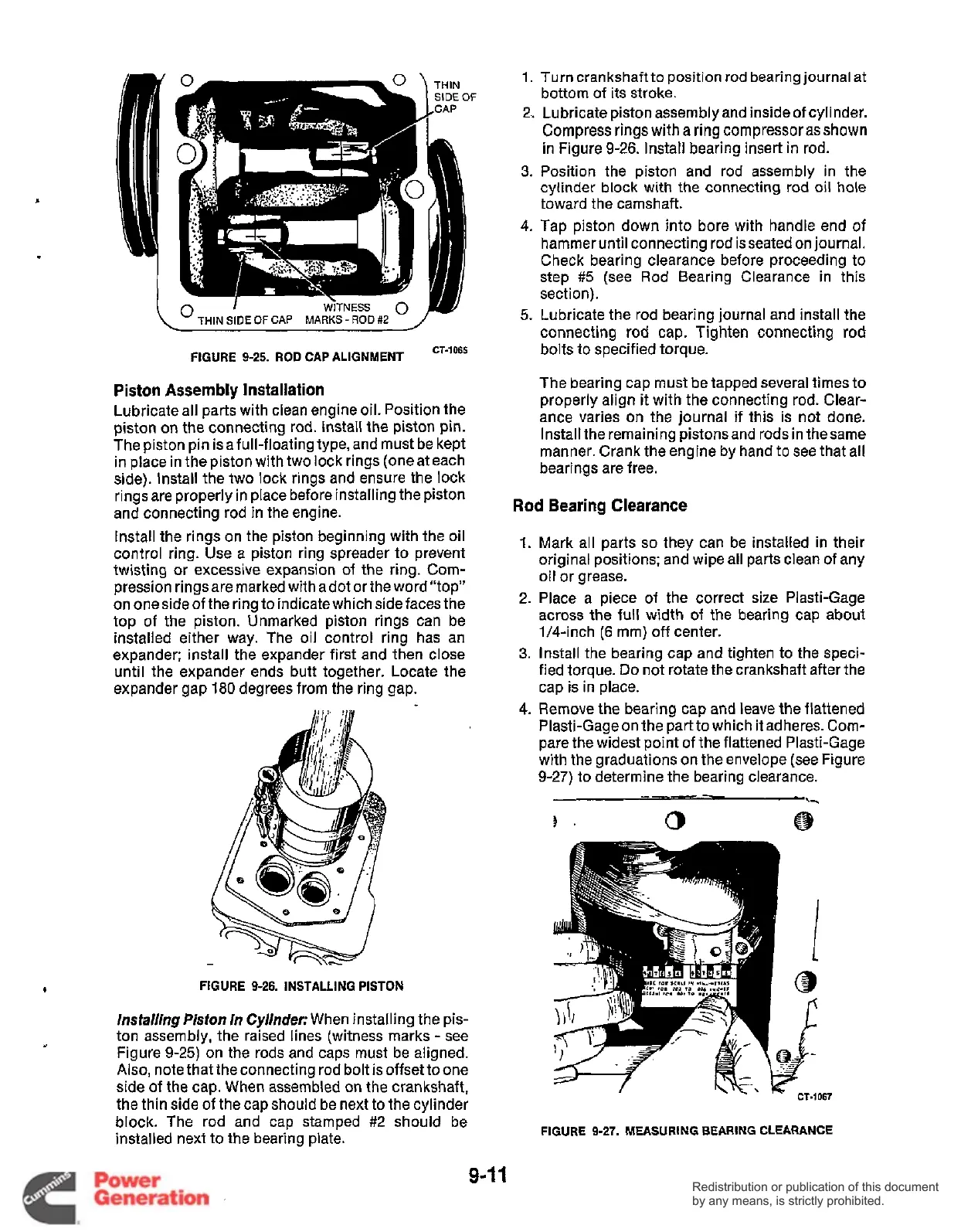

2. Place a piece of the correct size Plasti-Gage

across the full width of the bearing cap about

1/4-inch

(6

mm) off center.

3.

Install the bearing cap and tighten to the speci-

fied torque.

Do

not rotate the crankshaft after the

cap is in place.

4.

Remove the bearing cap and leave the flattened

Plasti-Gage on the partto which it adheres.

Com-

pare the widest point of the flattened Plasti-Gage

with the graduations on the envelope (see Figure

9-27) to determine the bearing clearance.

‘X-

3’

0

@

FIGURE

9-27.

MEASURING BEARING CLEARANCE

9-1

1

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...