MAINTENANCE

2.23

end of the muffler.

3. Use a non-synthetic brush to clean the arrestor screen. A

synthetic brush may melt if components are warm. If

necessary, blow debris from the screen with compressed

air.

4. Inspect the screen for wear and damage. Replace if

necessary.

5. Remove and inspect the gasket. Replace if worn or

damaged.

6. Reinstall the gasket and arrestor.

7. Use a wire brush to clean the arrestor screen. (NOTE: A

synthetic brush may melt if components are warm.) If

necessary, blow debris from the screen with compressed

air.

8. Reinstall the clean out plug and arrestor.

9. Torque screws to 50 in. lbs. (5.6 Nm).

BRAKE SYSTEM INSPECTION

The following checks are recommended to keep the brake

system in good operating condition. Service life of brake

system components depends on operating conditions. Inspect

brakes in accordance with the maintenance schedule and before

each ride.

• Keep fluid level in the master cylinder reservoir to

the indicated level inside reservoir.

• Check the fluid level “eye”. If it is clear, it is an

indication that fluid is needed or the brake pads may

be worn, which can reduce the fluid level.

• Use Polaris DOT 3 or DOT 4 Brake Fluid

• Check brake system for fluid leaks, excessive

travel or spongy feel.

• Check brake pads for wear, damage or looseness.

• Check surface condition of the disc.

• Inspect thickness of brake pad friction material.

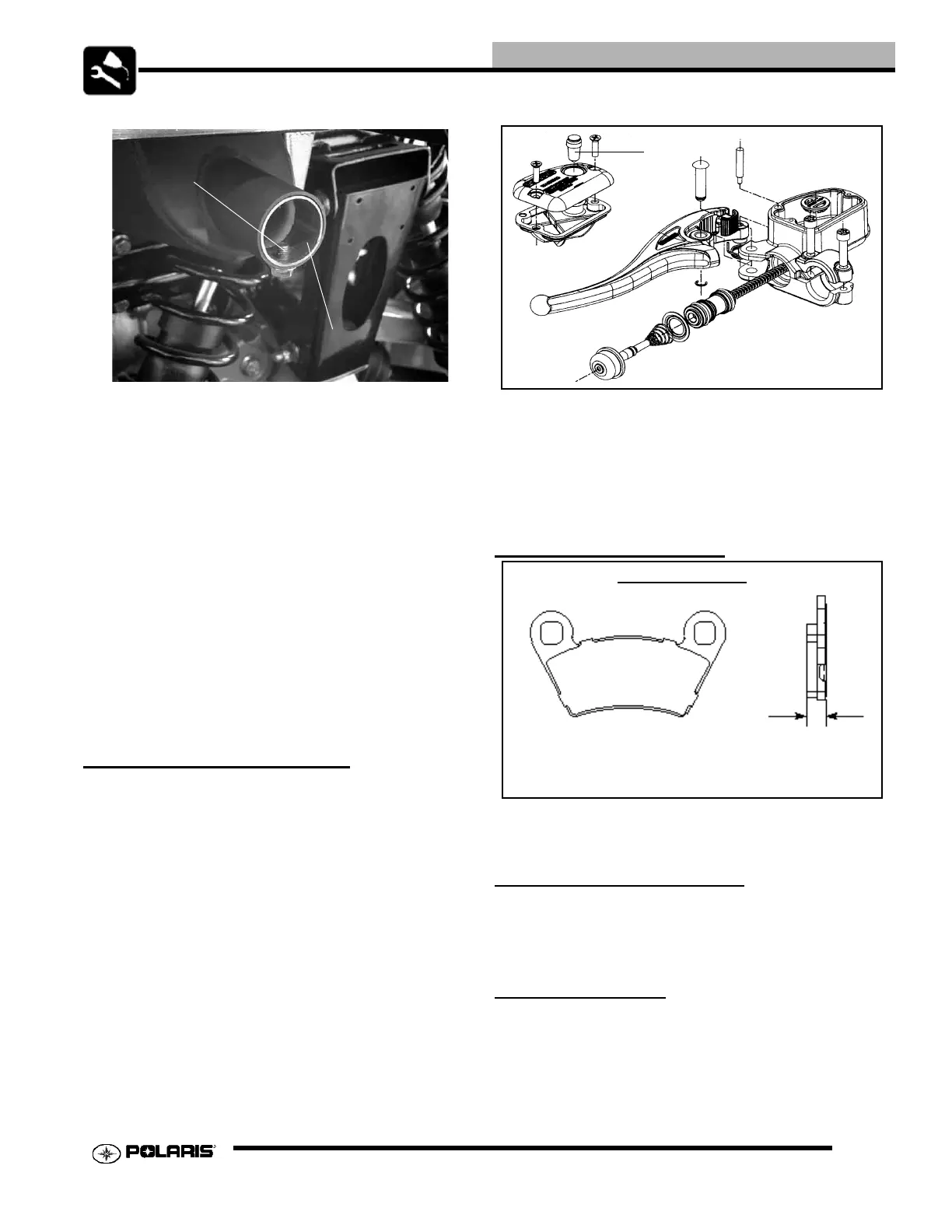

BRAKE PAD INSPECTION

Brake pads should be changed when friction material is worn to

.59” (1.5 mm).

HOSE/FITTING INSPECTION

Check brake system hoses and fittings for cracks, deterioration,

abrasion, and leaks.Tighten any loose fittings and replace any

worn or damaged parts.

BRAKE FREEPLAY

Hand Brake Lever

1. Check the brake lever, and foot brake for loose connections,

free play, and damage.

2. Measure the hand brake lever freeplay. Freeplay should be

1

Arrestor

SIGHT GLASS

Front Brake Pads

Brake Pad

Measure

Thickness

Service Limit - .059” (1.5 mm)

Loading...

Loading...