3.10

ENGINE

Crankshaft Straightening

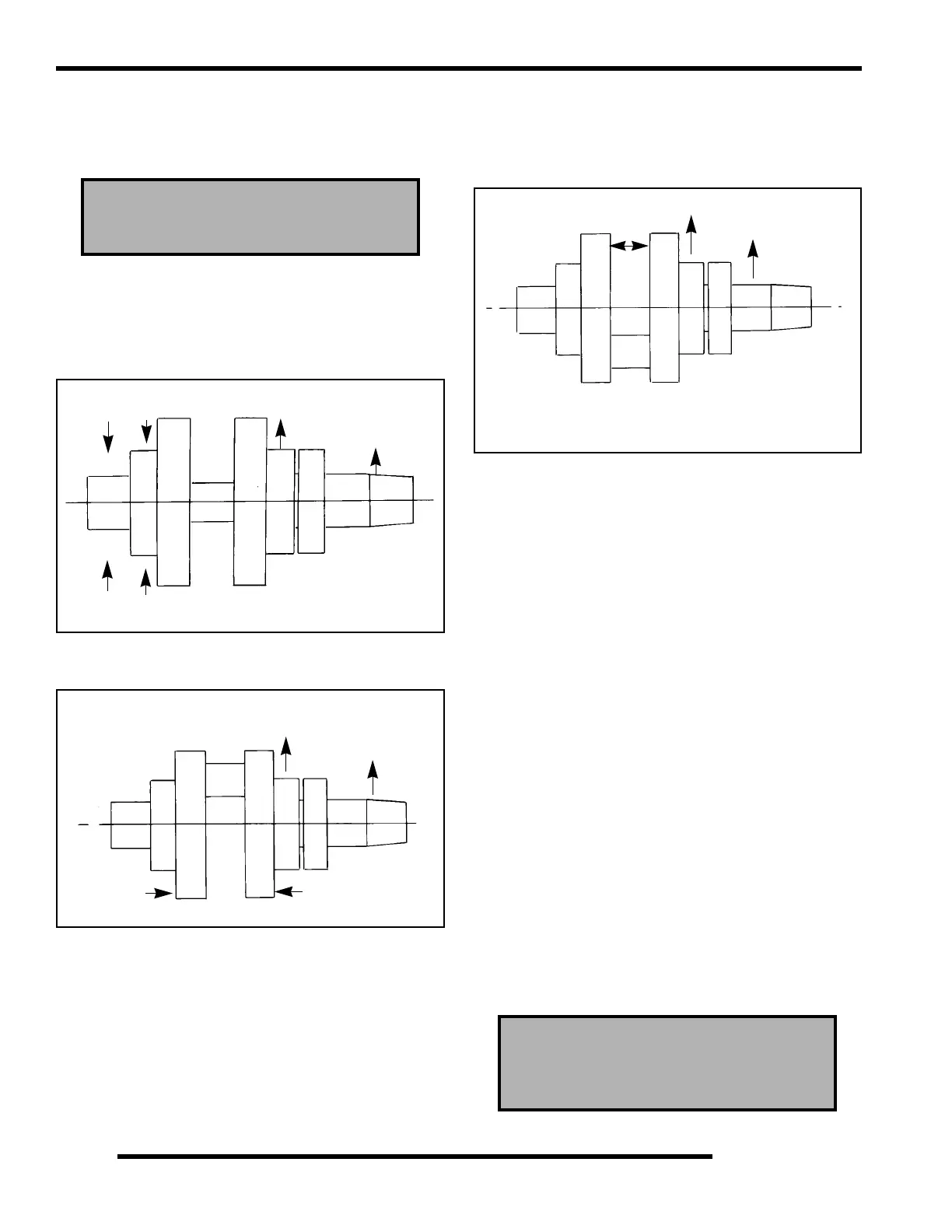

Lubricate the bearings and clamp the crankshaft securely in the

crankshaft alignment fixture. Refer to the illustrations below.

NOTE: The rod pin position in relation to the dial

indicator position tells you what action is required to

straighten the shaft.

1. To correct a situation like the one shown in the illustration,

strike the shaft at point A with a brass hammer.

2. To correct a situation like the one shown in the illustration,

squeeze the crankshaft at points A. (Use tool from

alignment kit).

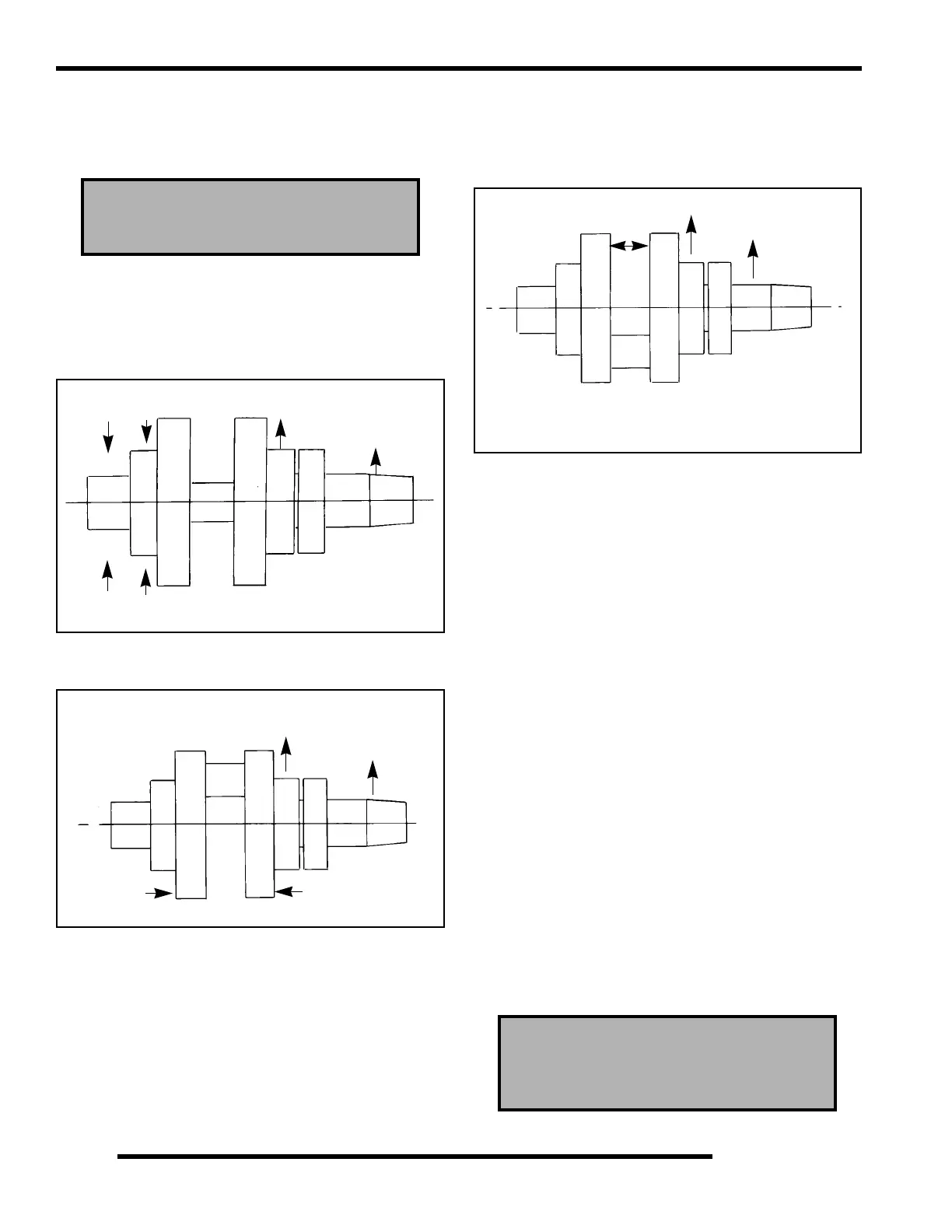

3. If the crank rod pin location is 180

o

from the dial indicator

(opposite that shown), it will be necessary to spread the

crankshaft at position A as shown in the illustration below.

When rebuilding and straightening a crankshaft, runout

must be as close to zero as possible.

NOTE: Maximum allowable runout is .0024”.

ES50PL Engine Lubrication

Oil Type:

Polaris PS-4 Synthetic (PN 2874414)

Capacity:

Approximately 2.25 U.S. Quarts (2.1L)

Filter:

(PN 3088036)

Drain Plug / Screen Fitting:

14.8 - 17 ft. lbs. (20-23 Nm)

(If fitting is removed, follow oil pump priming procedure).

Oil Pressure Specification:

20 PSI @ 5500 RPM, Polaris PS-4 Synthetic

(Engine Hot)

Oil Pressure Test

1. Remove blind plug on front right oil filter cover.

2. Insert a 1/8 NPT oil pressure gauge adaptor and attach the

gauge.

3. Start engine and allow it to reach operating temperature,

monitoring gauge indicator.

NOTE: Use only Polaris PS-4 Synthetic Engine

Lubricant (PN 2874414).

Crankshaft Alignment Fixture

(PN 2870569)

HIGH .004 (.1 mm)

HIGH .004 (.1 mm)

A

B

SUPPORT CRANKSHAFT HERE

HIGH .002 (.05 mm)

HIGH .005 (.13 mm)

AA

Oil Pressure at 5500 RPM (Engine Hot):

Standard: 20 PSI

Minimum: 12 PSI

AA

HIGH .002 (.05 mm)

HIGH .005 (.13 mm)

Loading...

Loading...