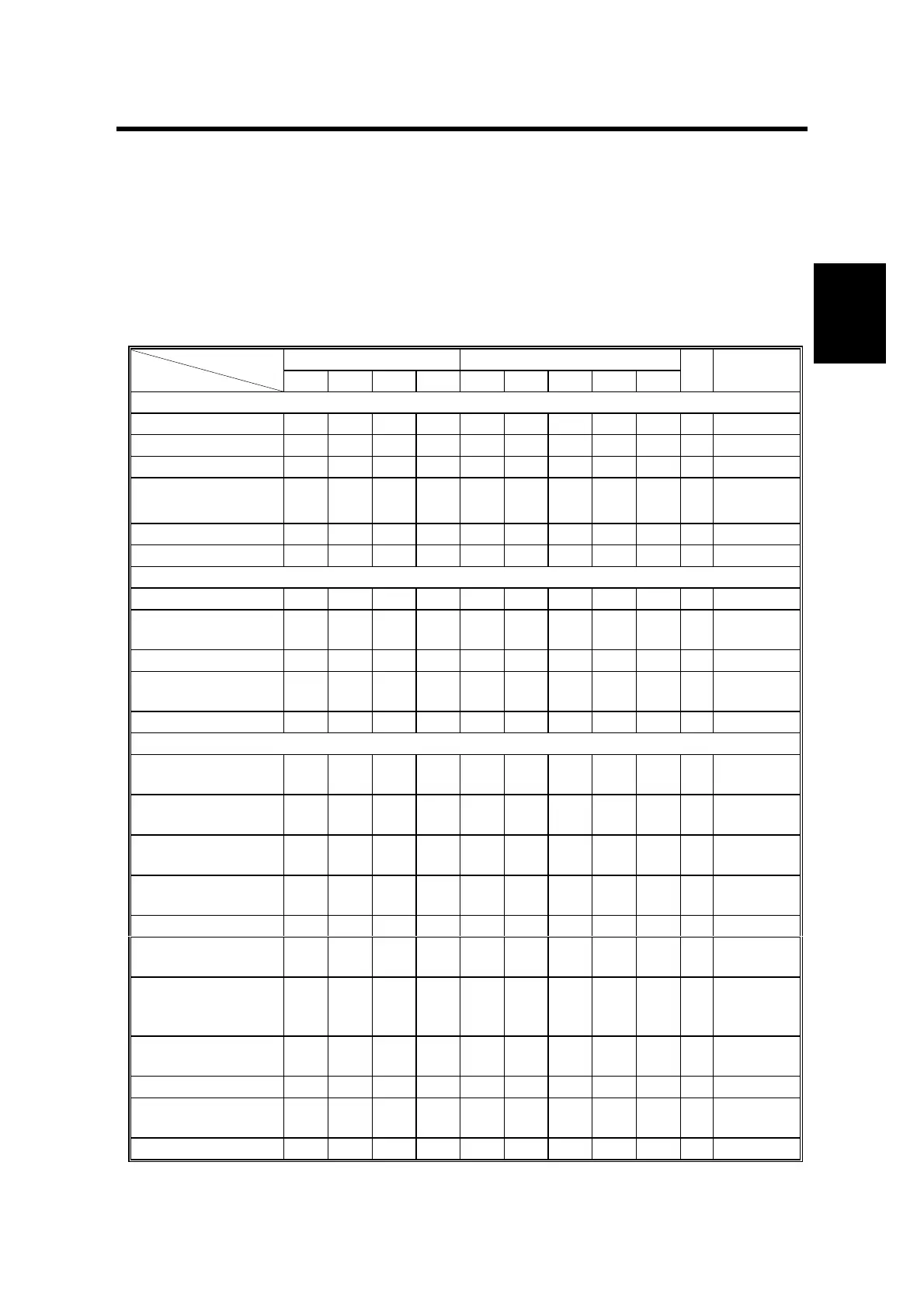

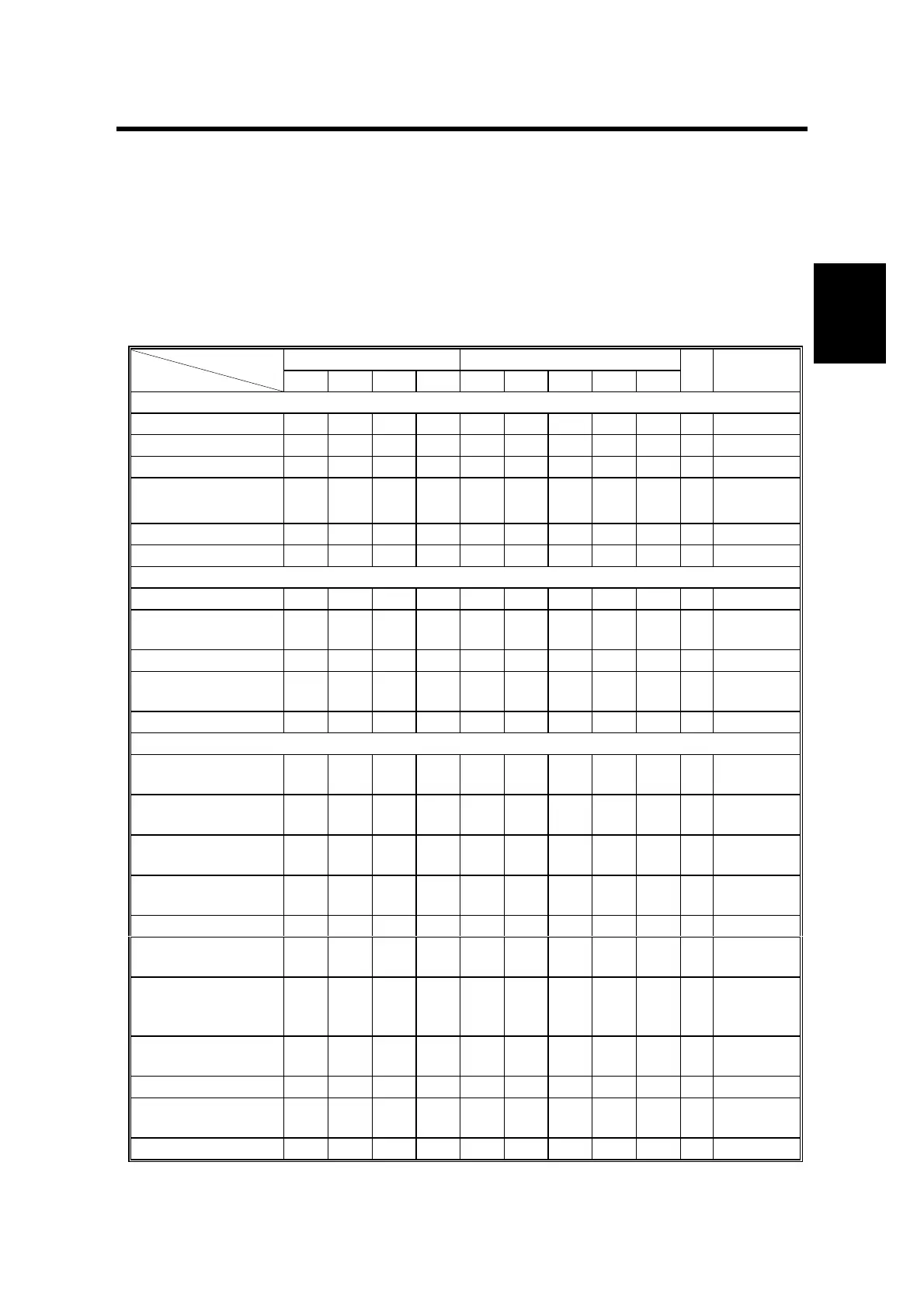

31 October 2001 MAINTENANCE TABLE

2-1

Preventive

Maintenance

2. PREVENTIVE MAINTENANCE

2.1 MAINTENANCE TABLE

The following items should be maintained periodically. There are two sets of

intervals - one based on time and the other based on print count. For maintenance

items with entries in both of them, use whichever comes first.

C: Clean, R: Replace, L: Lubricate, A: Adjust

Time Print CounterInterval

Item

6M 1Y 2Y 3Y

1M 1.2M

2M 2.4M 3M

EM NOTE

Scanner/Optics

Exposure Lamp C C C C Dry Cloth

Mirror/Reflector C C C C Soft Cloth

Scanner Guide Rail C C C C Dry Cloth

Platen Cover / White

Plate

CCCC

Damp

Cloth

Exposure Glass C C C C Dry Cloth

Master Feed

Thermal Head C Alcohol

Platen Roller

CCCC

Damp cloth

and water

Master Eject Rollers C C C C Alcohol

Drum Master

Sensor

C Dry Cloth

Paper Feed

Paper Pick-up Roller

CCRC R R

Damp

Cloth

Paper Feed Roller

CCRC R R

Damp

Cloth

Pick-up Roller/Feed

Roller Shafts [A]

LLL

Motor Oil

(SAE #20)

Friction Pad

CCRC R R

Damp

Cloth

Press Roller C C R C R R Alcohol

Table Fulcrum

Shafts [B]

LLL

Motor Oil

(SAE #20)

Table Racks [C]

LLL

Grease

(Alvania

#2)

Paper Delivery

Transport Belts

RRR

Paper End Sensor C C C C Dry Cloth

Registration/Exit

Sensors

CCCC Dry Cloth

Registration Roller C C C C Dry Cloth

Loading...

Loading...