PRINTING 31 October 2001

3-18

3.7.2 PRESS ROLLER RELEASE LEVER ADJUSTMENT

Purpose: To maintain the correct clearance between the press roller arms and

press roller lock levers. This ensures that the press roller is correctly released and

pressed against the drum when the press roller release solenoid is energized.

Standard: 0.7 to 1.2 mm

Tools: A thickness gauge

• Front cover (☛ 3.2.1)

• Rear covers (☛ 3.2.2)

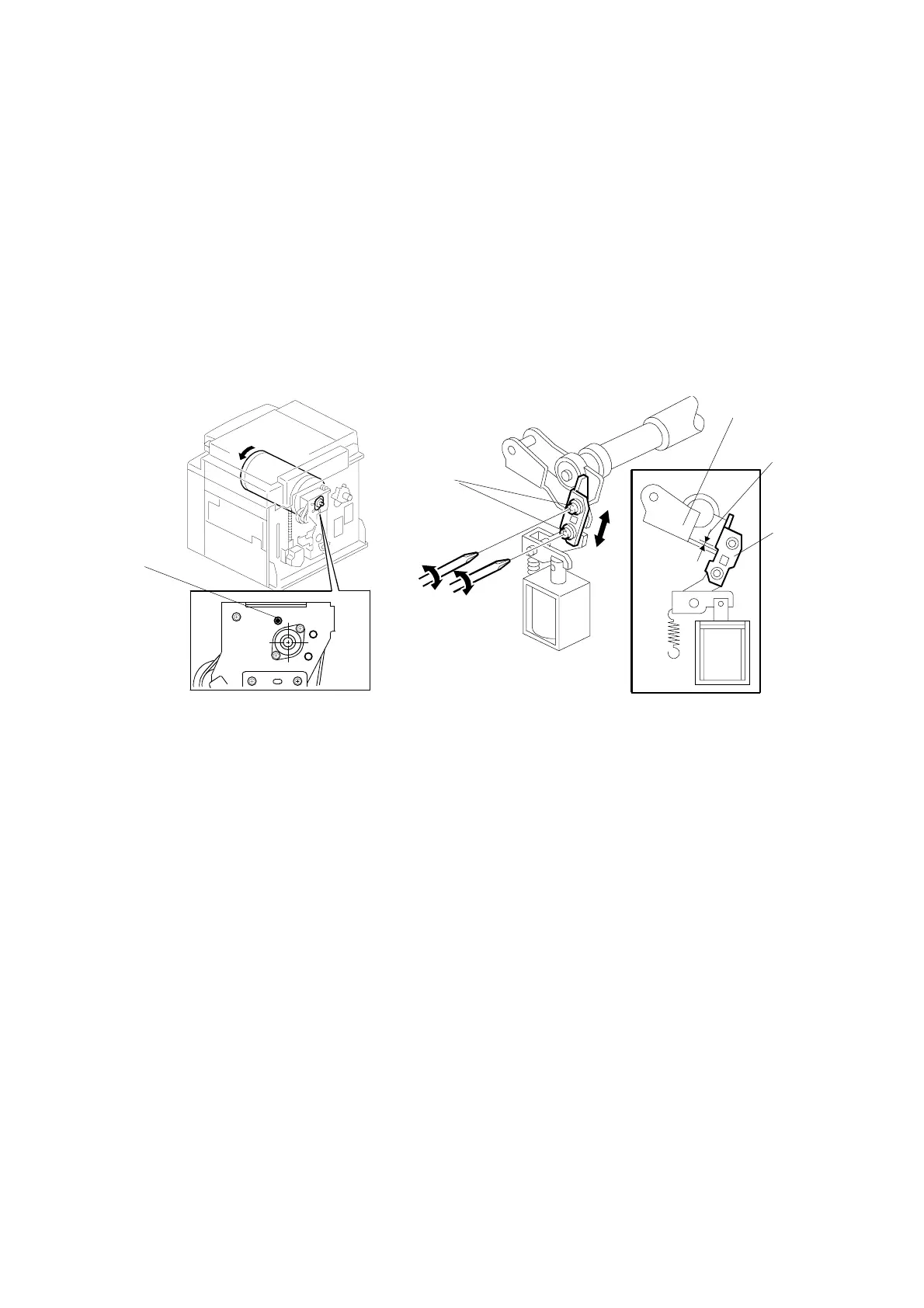

1. Turn the drum manually until the drum master clamper on the drum moves into

the lowest position. (This is when the high points of the cams on the drum

flanges meet with the cam followers on both ends of the press roller.)

• To find out the correct position of the drum for the adjustment, look at the

rear end of the drum shaft. The recess on the drum drive gear meets the hole

[A] in the bracket when the drum is in the correct position.

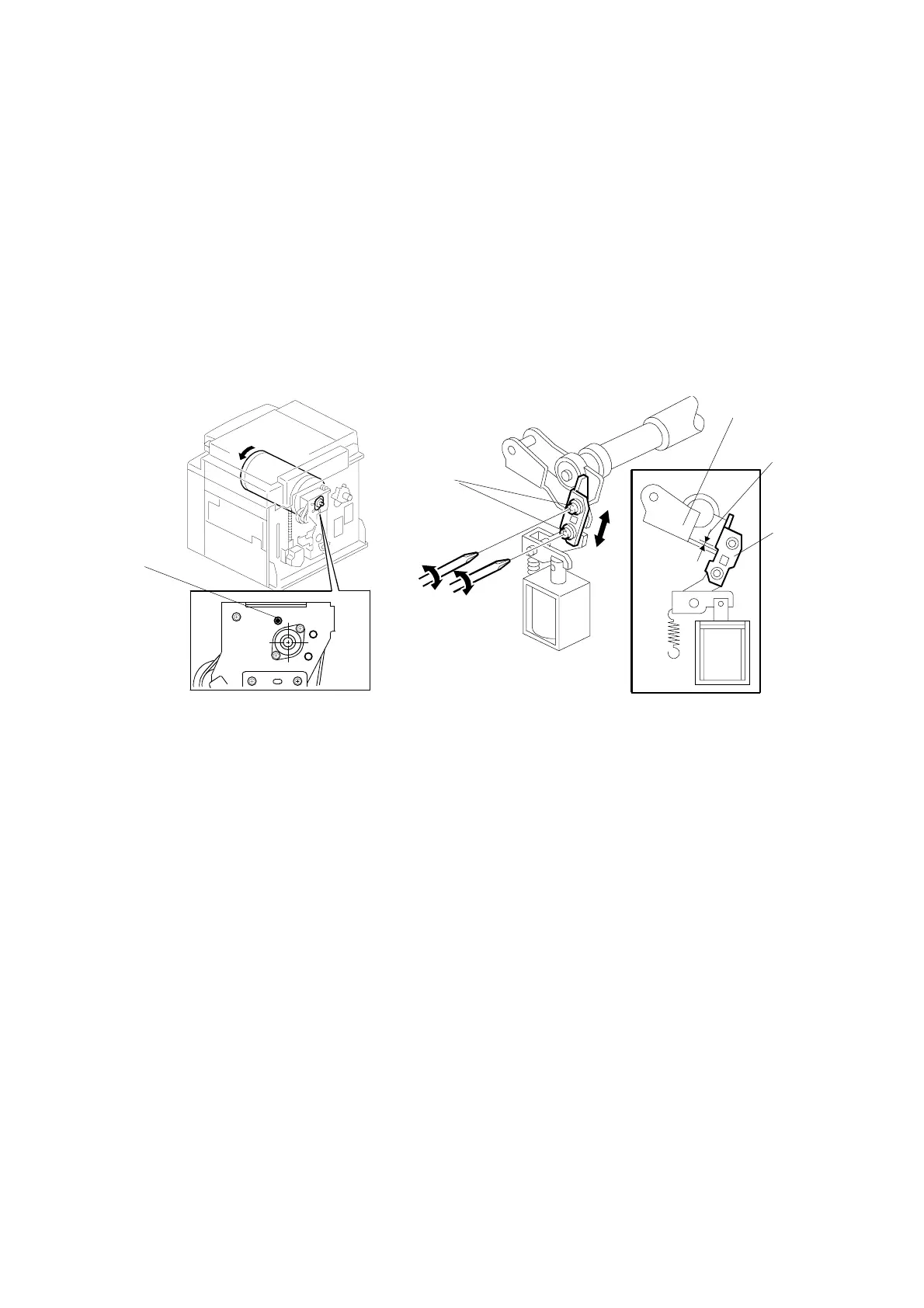

2. Using a thickness gauge, measure the clearance [B] between the press roller

arm [C] and the press roller lock lever [D] (rear side). It should be between 0.7

and 1.2 mm.

3. If it is not correct, adjust the position of the press roller lock lever after

loosening the two screws [E].

4. Repeat steps 2 and 3 for the front side.

C238R001.WMF

C238R051.WMF

[A]

[B]

[C]

[D]

[E]

Loading...

Loading...