PAPER DELIVERY 31 October 2001

3-30

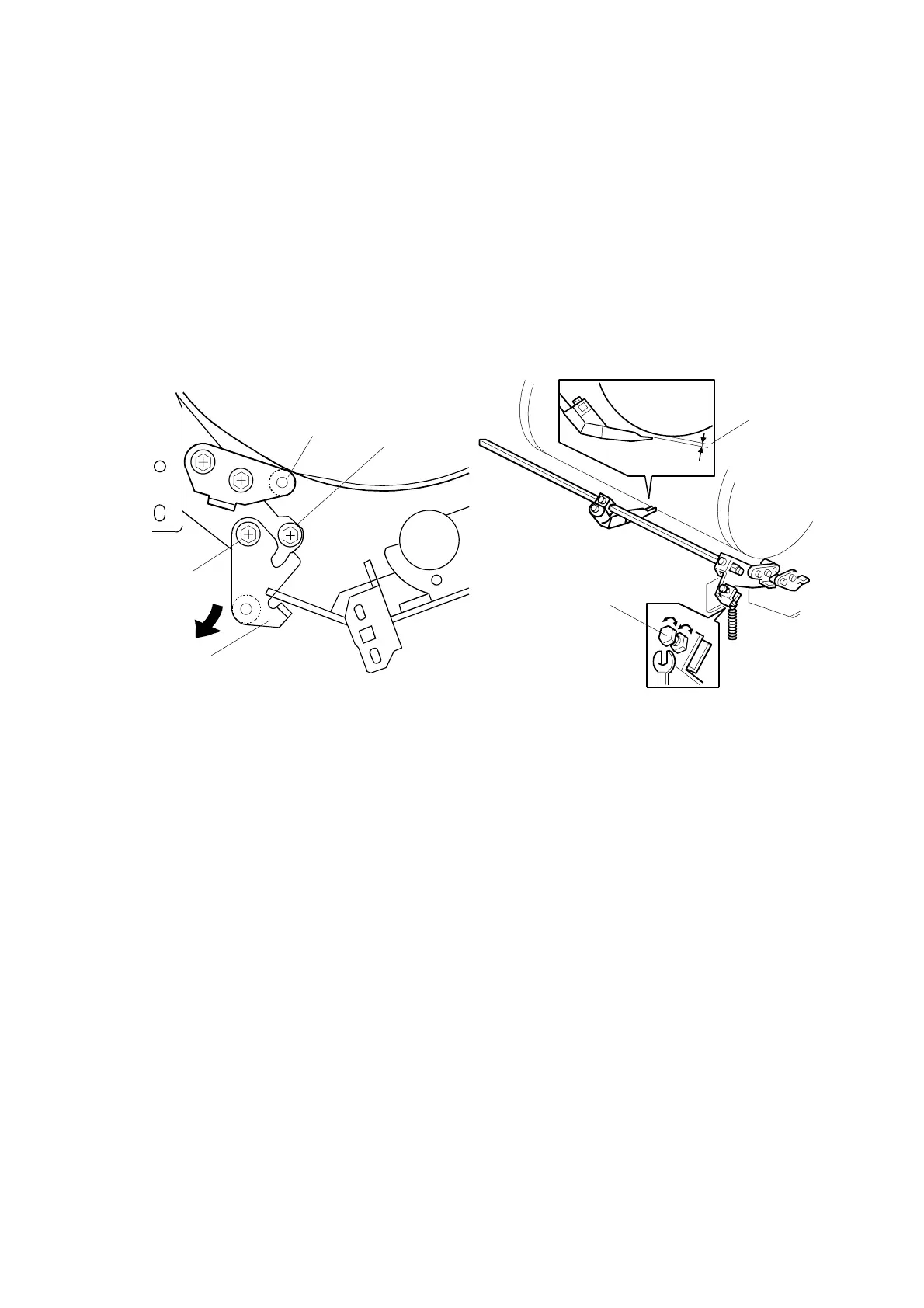

3.9.3 EXIT PAWL ADJUSTMENT

Purpose: To ensure that the exit pawls can move out of the way of the drum master

clamper while the drum is rotating.

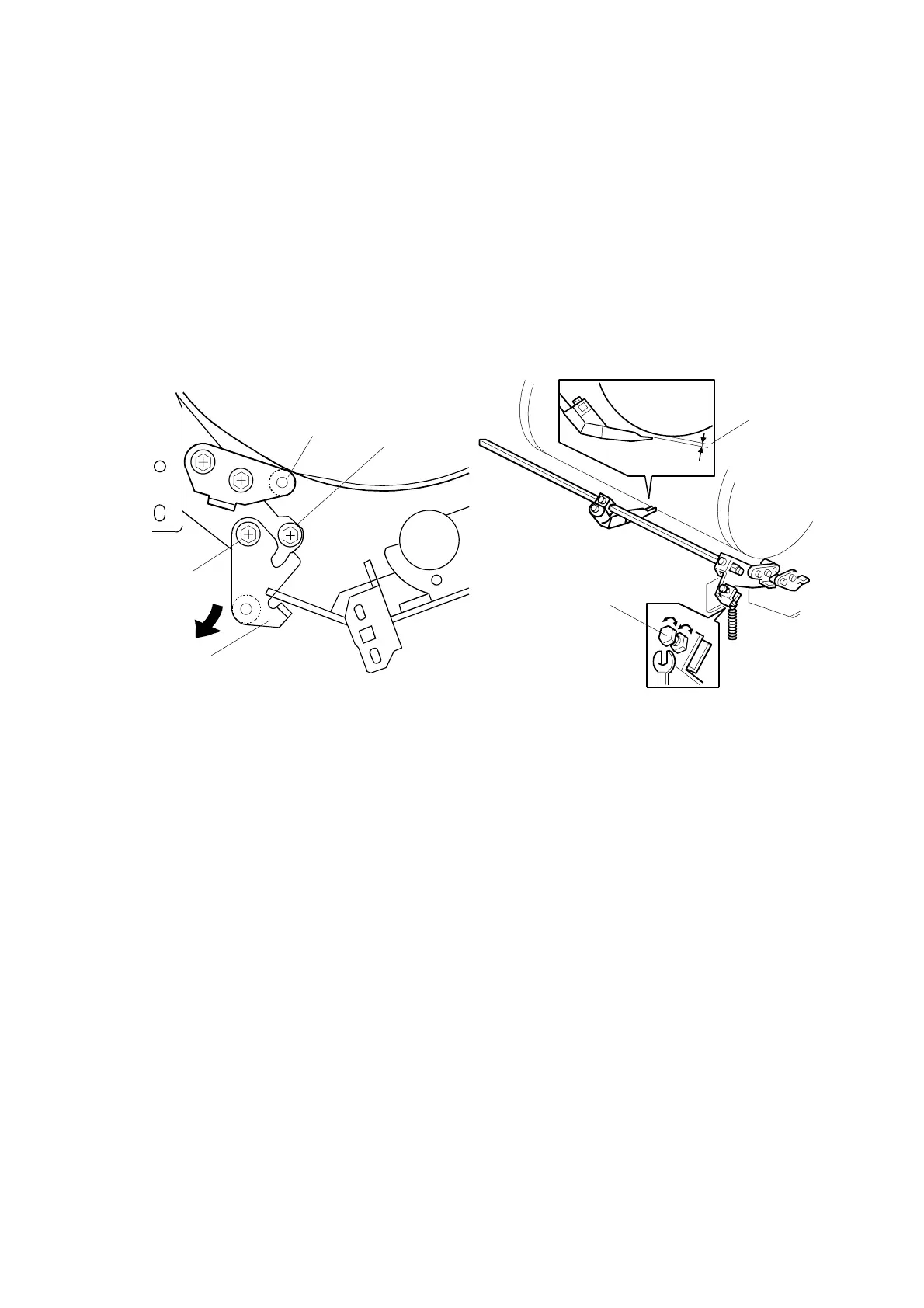

Clearance adjustment

Standard: Within 1.15 ± 0.15 mm

• Front cover (☛ 3.2.1)

1. Loosen screw [A] then screw [B] in this order (do not remove them). Make sure

that the bracket [C] becomes free from engagement and the cam follower [D]

contacts the drum flange.

2. Using a gap gauge, measure the clearance [E] between the drum surface and

the exit pawls. It should be 1.15 ± 0.15 mm.

3. If the clearance is not correct, adjust the clearance by turning the bolt [F].

4. Reposition the bracket [C] and tighten the screws [A] and [B].

5. Do the timing adjustment (see the next page).

C238R061.WMF

C238R034.WMF

[A]

[B]

[C]

[D]

[E]

[F]

Loading...

Loading...