6.Troubleshooting

228

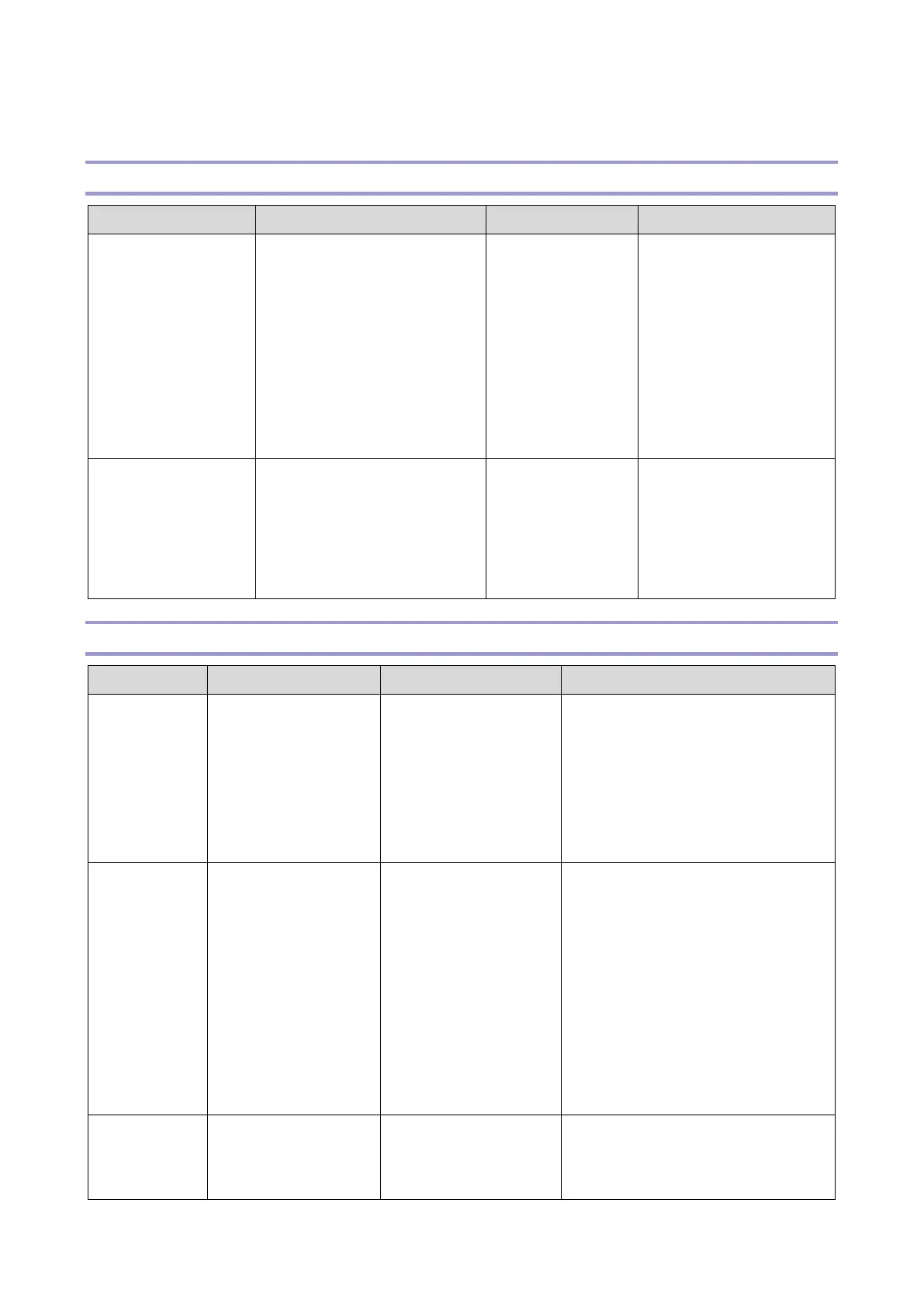

Paper Delivery Problems

Image Has Shifted Out of Position

Double colors

(colors out of

position) in text or

heavy coverage

areas

Poor positioning caused by

the change in temperature

during printing.

Can occur at the

beginning of

machine use or

over time.

Can occur during

a long print job.

To correct out of position

colors:

Printer model: Menu

key > System settings >

Color Den/Reg

MF model: Settings icon

> System settings >

Color Registration

Image slipped out of

position at the

leading edge of the

paper

Paper tray was set without

pushing down the bottom

plate of the tray, causing the

leading edge to slip.

Can occur at the

beginning of

machine use or

over time.

• Check installation of

the paper tray.

• Adjust paper

registration in the

SP mode.

Tears occur in

the center of

paper leading

edges

Paper tray was set

without pushing

down the bottom

plate of the tray,

causing the leading

edge to slip.

Can occur after

adding fresh paper to

paper tray.

Can occur at the

beginning of machine

use or over time.

Check installation of the paper tray.

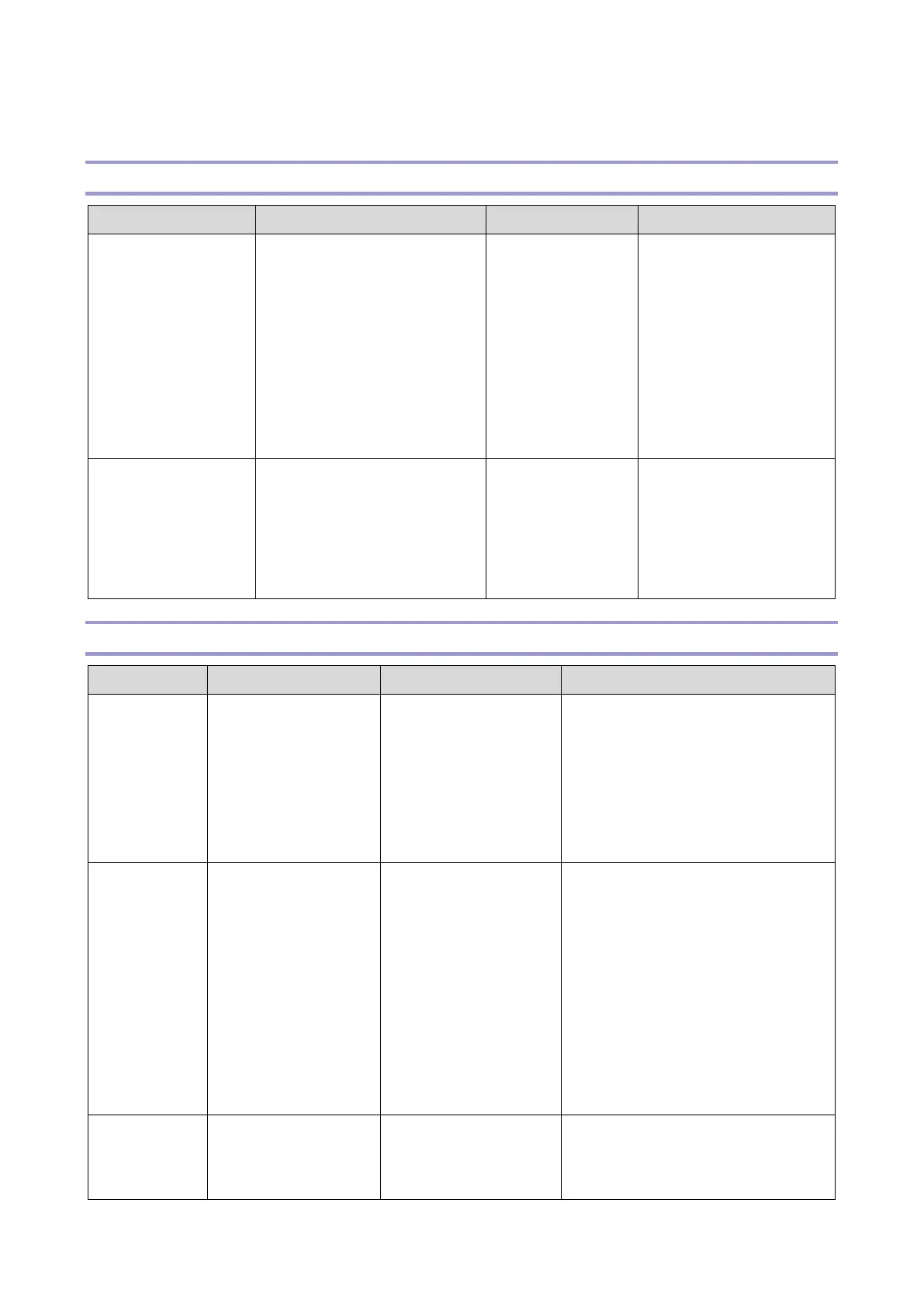

Both corners

of leading

edge become

dog eared

Dog-earing can be

caused by both

corners of the

leading edge getting

caught in the paper

transport path.

If the paper is thick

and has been left

unwrapped for a long

time, or it is recycled

paper, replace with

normal paper.

• Confirm that paper is set

correctly in the tray. (Problems

can occur with leading/trailing

edges, front/back sides of

paper in the paper feed path

with paper from different lots.)

• Make sure that paper is stored

correctly in its vinyl packs until

ready for use.

Paper in the feed tray

can easily stick

together.

Leading edges of the

paper are burred.

Fan the paper stack before loading

it in the tray (this gets air between

the sheets of paper).

Loading...

Loading...