6.Troubleshooting

230

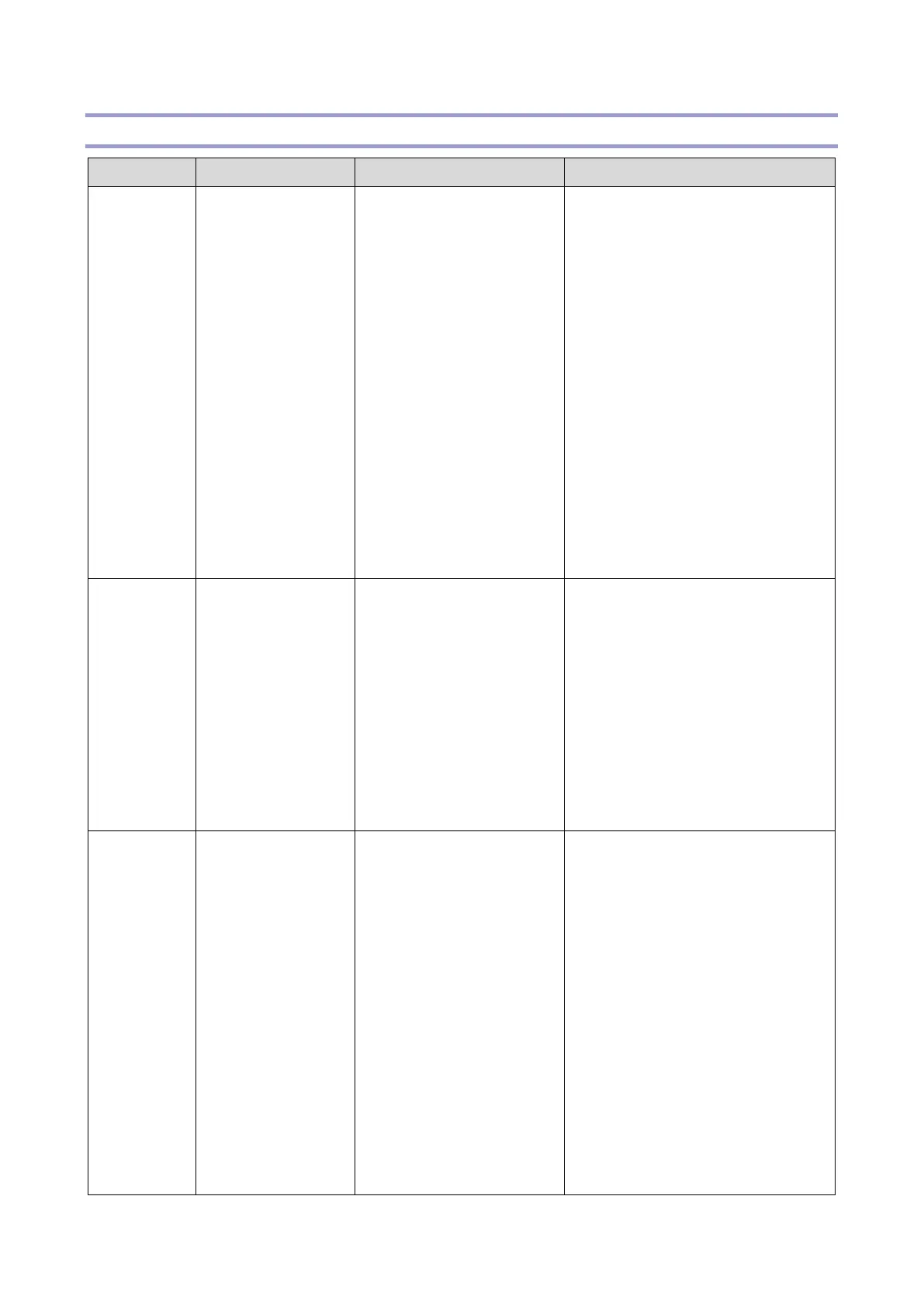

Poor Paper Feed

Paper not

feeding

correctly

Paper set

incorrectly

Paper in poor

condition

If the paper is thick and

has been left unwrapped

for a long time, or it is

recycled paper, replace

with fresh normal paper.

• Check installation of the paper

tray.

• Remove the stack and fan it to

remove static cling.

• Change the paper orientation

(switch front-to-back end, turn

over front-to-back), also ease

of feed can differ between

paper lots.

• Clean the feed rollers.

• Clean the separation pad.

• Make sure that paper is stored

correctly in its vinyl packs until

ready for use.

Both

corners of

leading

edge

become dog

eared

Dog-earing can be

caused by both

corners of the

leading edge

getting caught in

the paper transport

path.

If the paper is thick and

has been left unwrapped

for a long time, or it is

recycled paper, replace

with fresh normal paper.

• Confirm that paper is set

correctly in the tray. (Problems

can occur with leading/trailing

edges, front/back sides of the

paper in the paper feed path

with paper from different lots.)

• Make sure that paper is stored

correctly in its vinyl packs until

ready for use.

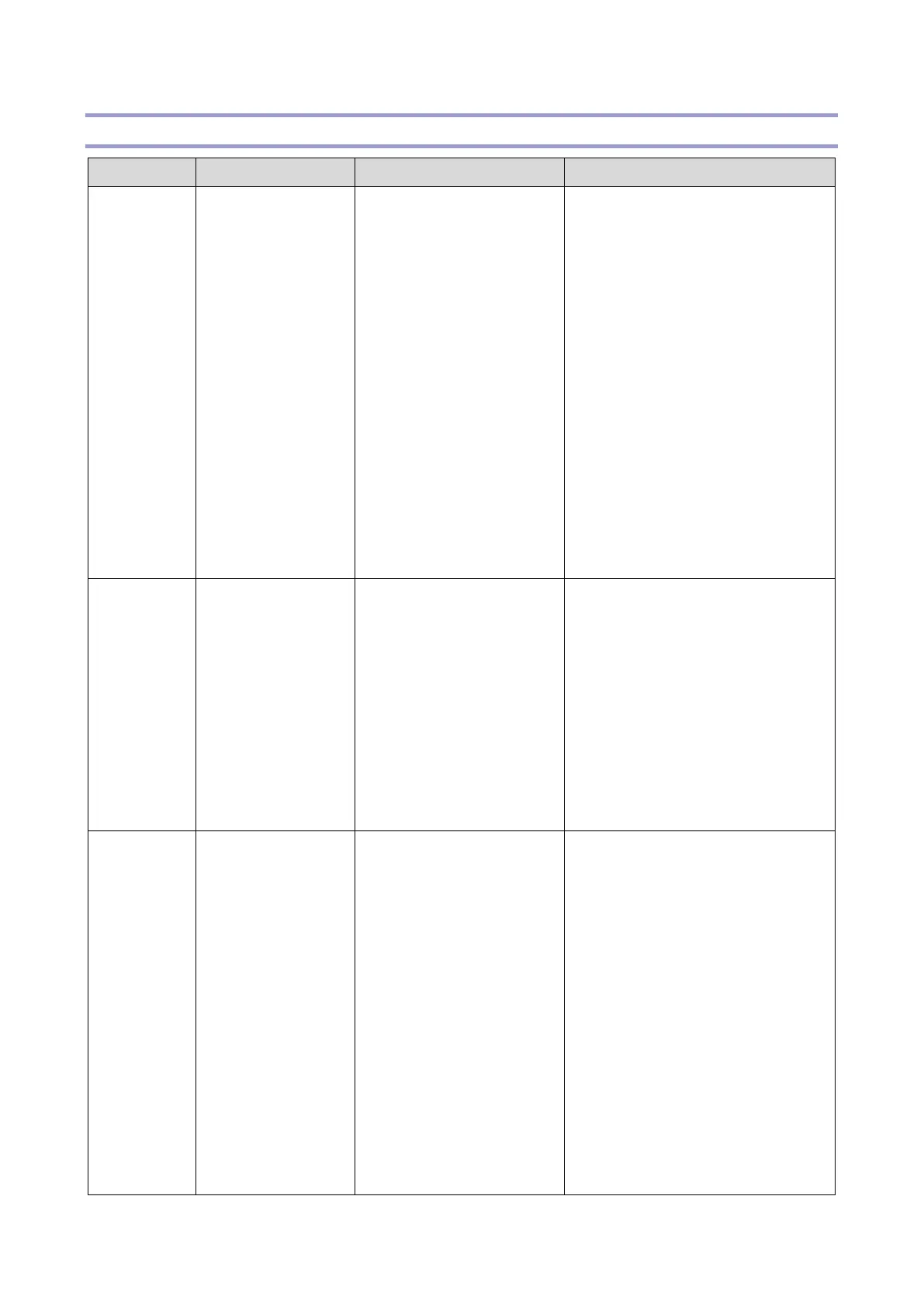

Paper in the feed

tray can easily stick

together.

The following can cause

problems:

• If the paper is thick

and has been left

unwrapped for a long

time, or it is recycled

paper, replace with

normal paper.

• Adding paper while a

job in progress.

• Using a previously

printed paper.

• Paper tray

• Check installation of the paper

tray.

• Remove the stack and fan it to

remove static cling.

• Change the paper orientation

(switch front-to-back end, turn

over front-to-back), also ease

of feed can differ between

paper lots.

• Clean the feed rollers.

• Clean the separation pad.

• Clean the registration roller.

• Make sure that paper is stored

Loading...

Loading...