9. Troubleshooting Guide RICOH Ri 2000 User Manual

203

9. Troubleshooting Guide

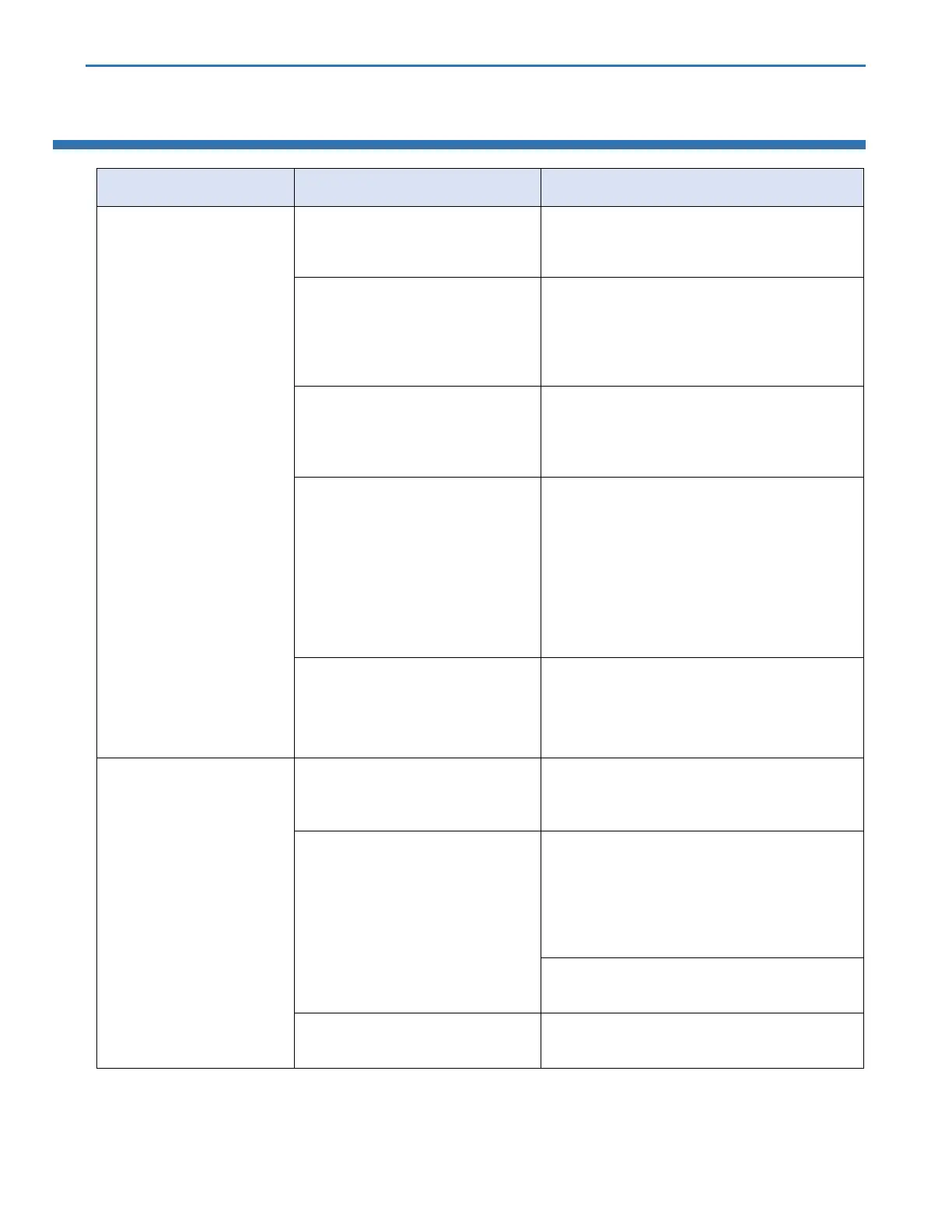

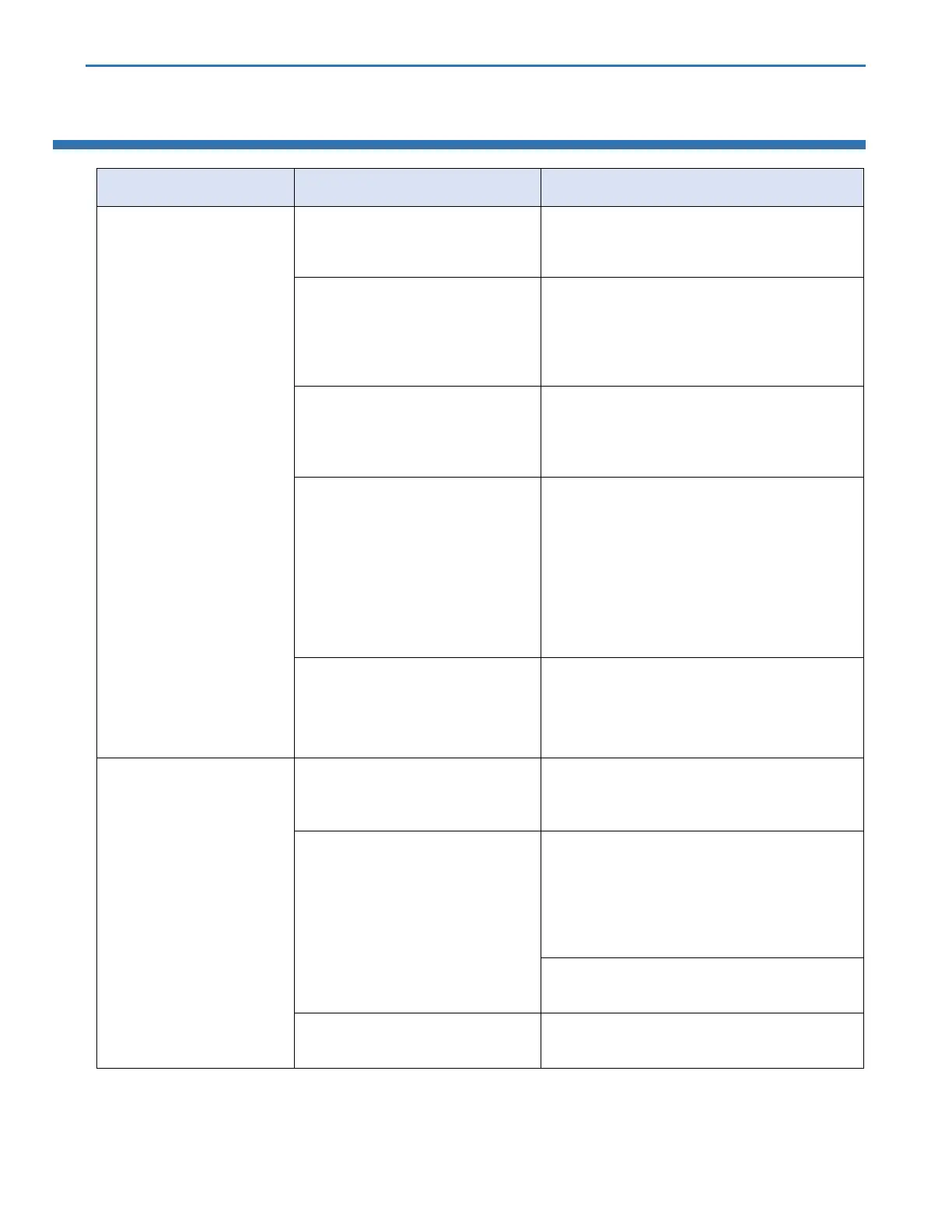

Issue/ Error Causes Solutions

Fuzzy blurry prints Table height is too low. Set the garment correctly on the platen,

and then perform HEIGHT ADJUST again.

Too much ink (oversaturated)

causing bleeding (mostly for

white or light shirts without

pretreat).

Check the settings in ColorGATE

Productionserver. Especially rendering

intent (perceptual is default and should be

used in most cases). Make sure you have

not changed profiles selection.

Nozzle check shows all

nozzles, but some areas show

deflection. (See page 124,

“NOZZLE CHECK”.

Perform normal nozzle cleaning or strong

nozzle cleaning, and then recheck the

nozzles to see if the deflection is gone.

For dark shirts with a white

Underbase, poor pretreat. Not

enough pretreat can make the

white can CMYK areas of print

to appear dull or fuzzy.

Especially if a section of the

print appears sharp and

another section appears dull or

fuzzy.

Check the dilution ratio of the pretreatment

and the coating/drying method again.

For details, see page 92, “Pre-treatment of

Dark Colored Garments”.

Head alignment is off.

Perform the head alignment procedure

(see page 175, “Adjusting the Head”).

Make sure to rule out the above reasons

before this adjustment.

Horizontal banding and

thin horizontal lines

across the entire shirt

Nozzles are missing. A nozzle

check may show some nozzles

are missing.

Perform head cleaning of CMYK print

head to clear the clogged nozzles.

Nozzles are all accounted for,

but some are showing minor

deflection.

Check the table height. The effect of any

deflection can be exaggerated if the

printing surface is too far away from the

head. Set the garment correctly on the

platen, and then perform HEIGHT

ADJUST again.

Perform head cleans until the deflection is

reduced.

Nozzles are 100% and little to

no deflection.

Perform the table alignment procedure

(see page 178, "Adjusting the Table").

Loading...

Loading...