Design Guidelines

Transport System Design

QuickStick HT User Manual 111

Rockwell Automation Publication MMI-UM007F-EN-P - September 2020

Wheel Materials

Some examples of commonly used wheel materials and key considerations:

Steel:

• Durable, typically used in systems that move heavy payloads or for difficult environ-

mental conditions.

• Low rolling resistance.

• When used on a metal guideway are typically noisier than plastics.

Plastic, Teflon, or Urethane:

• Plastics with a high durometer number (hardness) are a good choice of wheel material

for many applications, particularly for systems with moderate to low payload weights.

• Plastic or urethane wheels can develop a small flat area if the vehicle remains station-

ary for a long time period due to the vehicle mass and the magnet attractive force. In

most cases, these flat spots disappear after the vehicle is put in motion again.

• Higher rolling resistance than steel, but usually operate more quietly than steel wheels

when used on a metal guideway.

• Typically requires the vehicle be grounded to the guideway with static brushes.

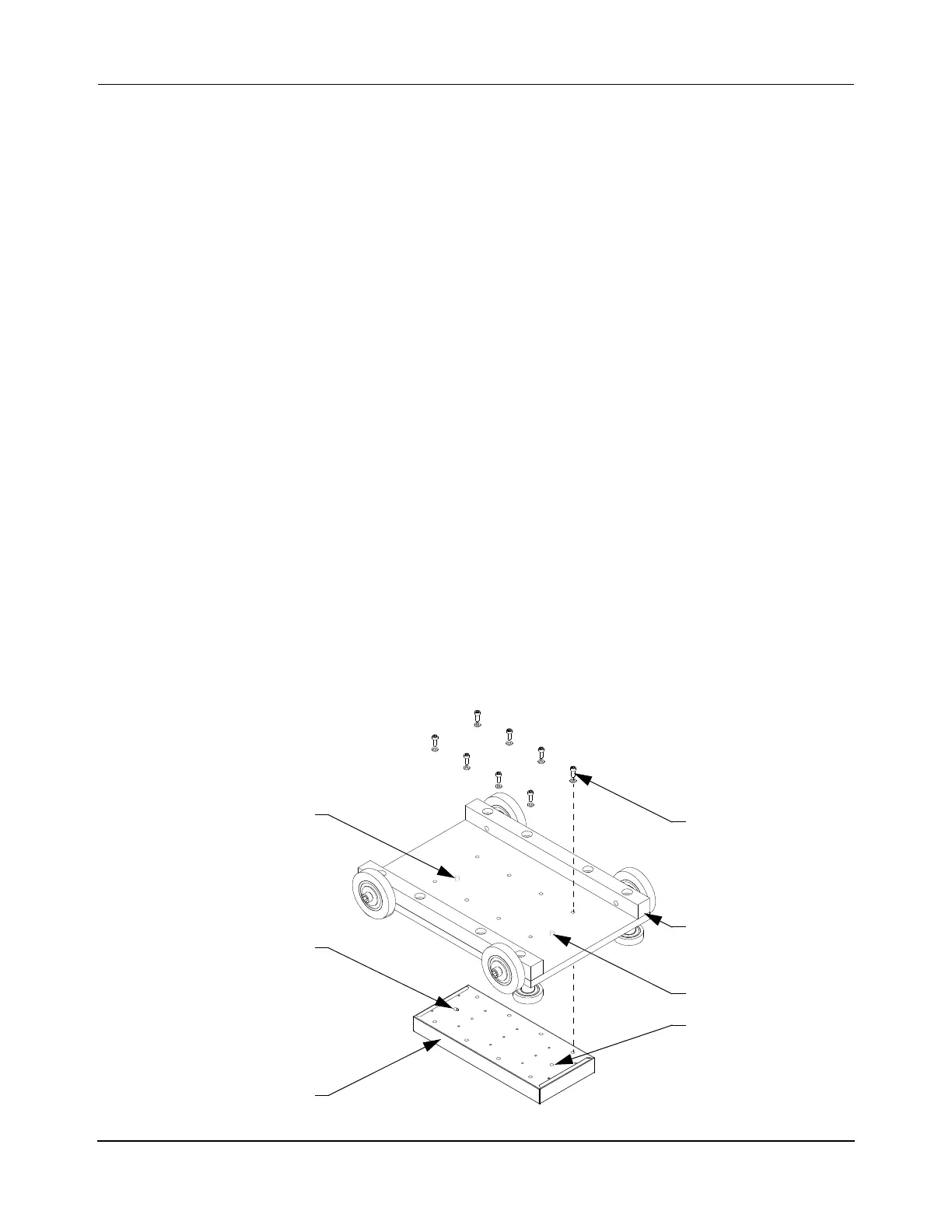

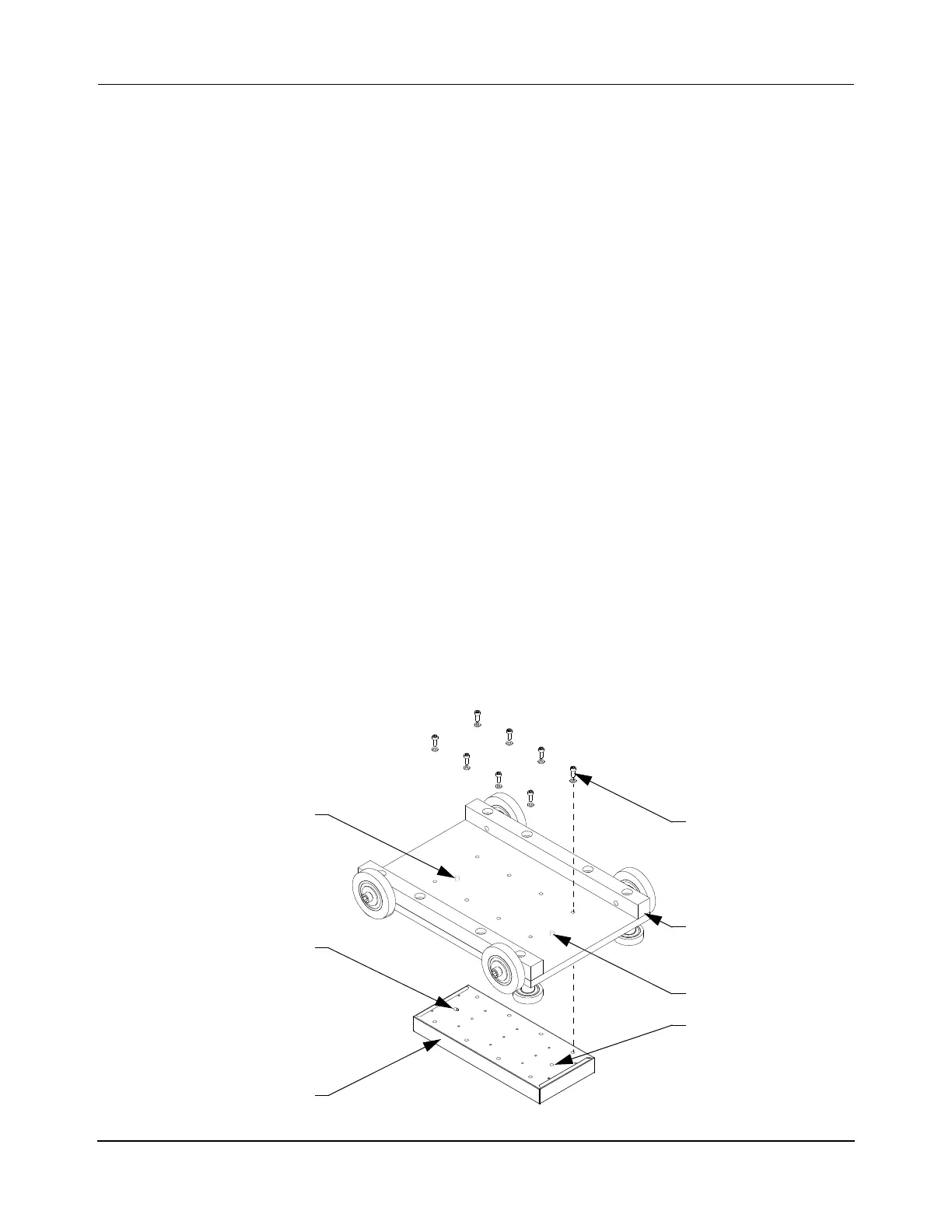

Mounting Magnet Arrays to Vehicles

Magnet arrays are provided with locating features to provide consistent mounting to the vehi-

cles and threaded holes for attachment. Arrays must be attached using stainless steel hardware

that fully engages the threads in all magnet array mounting holes as shown in Figure 3-36.

Figure 3-36: Magnet Array Mounting

Locating Hole

Mounting Hardware

Locating Pin

Vehicle

Locating Pin

Locating Slot

Magnet Array

Loading...

Loading...