Maintenance

Troubleshooting

294 MagneMotion

Rockwell Automation Publication MMI-UM007F-EN-P - September 2020

Motion Control Troubleshooting

This section covers the determination of motion-related problems within the QuickStick HT

transport system.

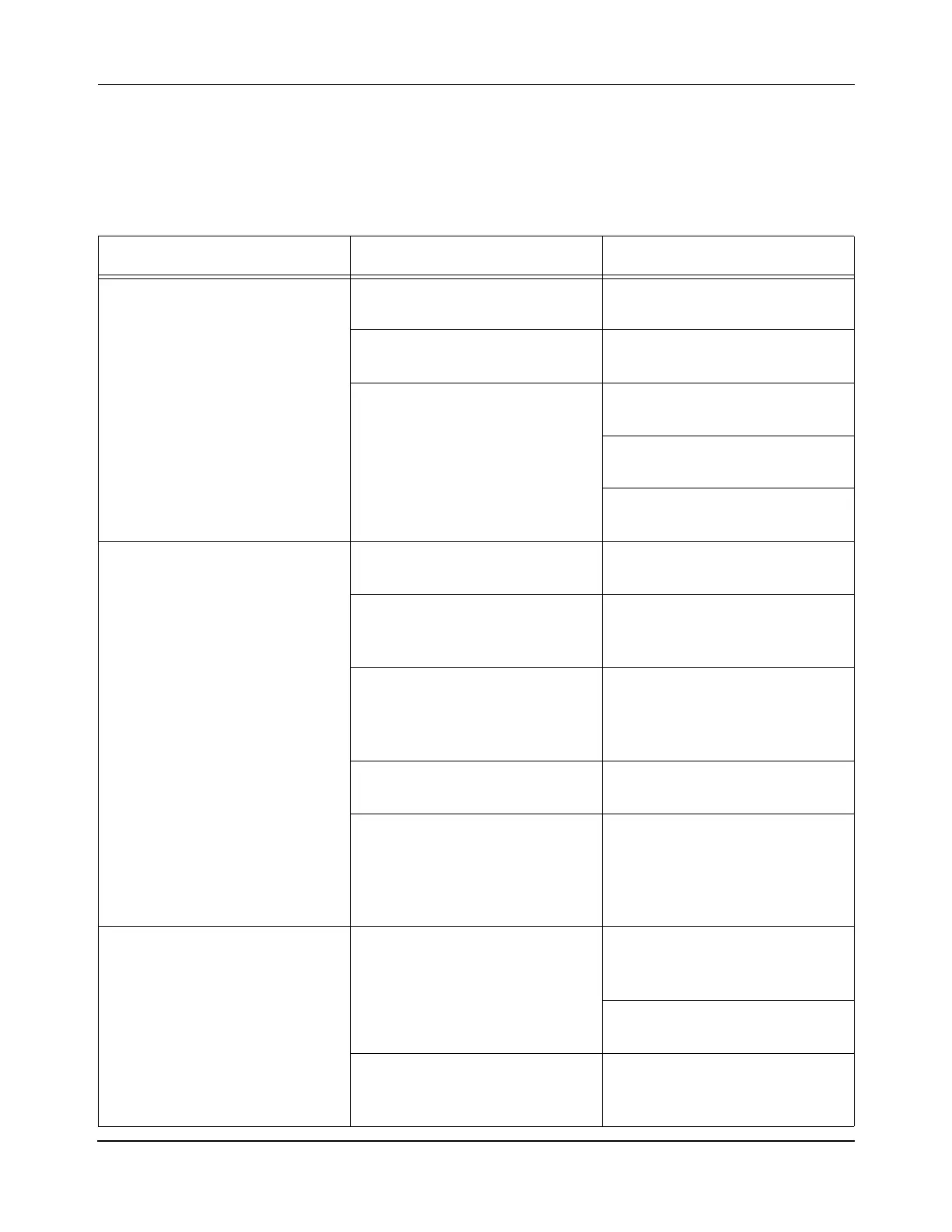

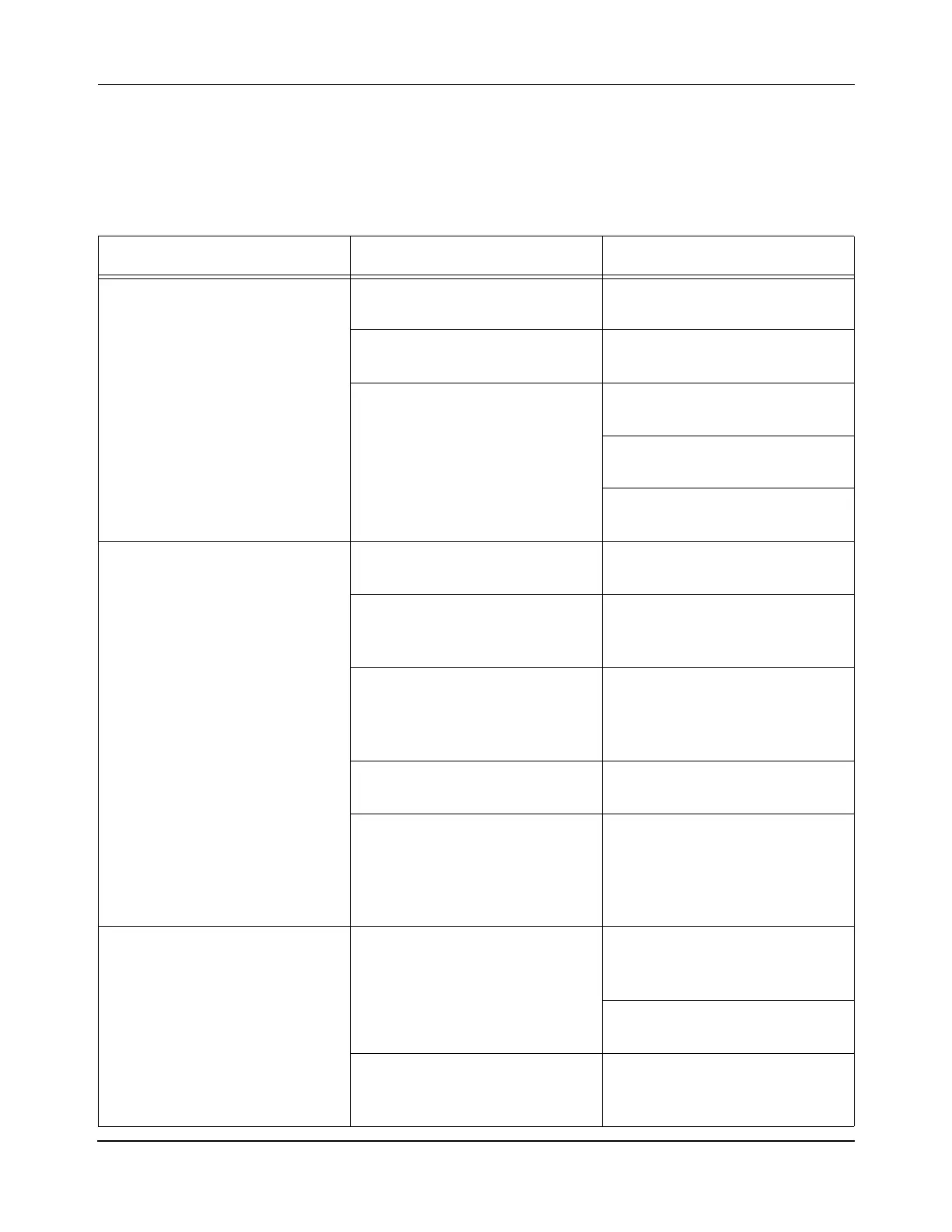

Table 8-6: Motion Control Related Troubleshooting

Symptom Problem Description Corrective Action

Material slips while the vehicles

are in motion.

Vehicle is not designed to carry

that specific material.

Make sure that the vehicle design

is correct.

Vehicle is not holding the material

securely.

Make sure that all material con-

tact surfaces are clean.

Motion configuration issue. Make sure that the vehicle accel-

eration is correct.

Make sure that the vehicle speed

is correct.

Make sure that the PID values are

correct.

Vehicles do not move smoothly or

motion is noisy.

Debris on the guideway. Make sure that the guideways and

motors are clean.

Misalignment of sections of the

guideway.

Make sure that the joints between

guideway sections are properly

secured and co-planar.

Power or communication to the

affected motors is lost or intermit-

tent.

Make sure that the power and

communication cables to all

motors and motor drives are prop-

erly seated.

Motion configuration issue. Make sure that the PID values are

correct.

Excessive noise when the vehicle

moves from section to section of

the guideway.

Make sure that the motors are

properly mounted and the transi-

tion from one section of guideway

to the next is smooth (sections

must be at the same height).

Vehicles are loosing thrust. Misalignment or wear of sections

of the guideway.

Make sure that the Vehicle Gap is

consistent at all locations on the

guideway.

Make sure that the vehicle and/or

track wear is within tolerance.

Thrust is lost when the vehicle

moves from motor to motor.

Make sure that the Downstream

Gap does not exceed 10% of the

magnet array length.

Loading...

Loading...