Rockwell Automation Publication 7000-UM202H-EN-P - November 2023 113

Chapter 2 Power Component Definition and Maintenance

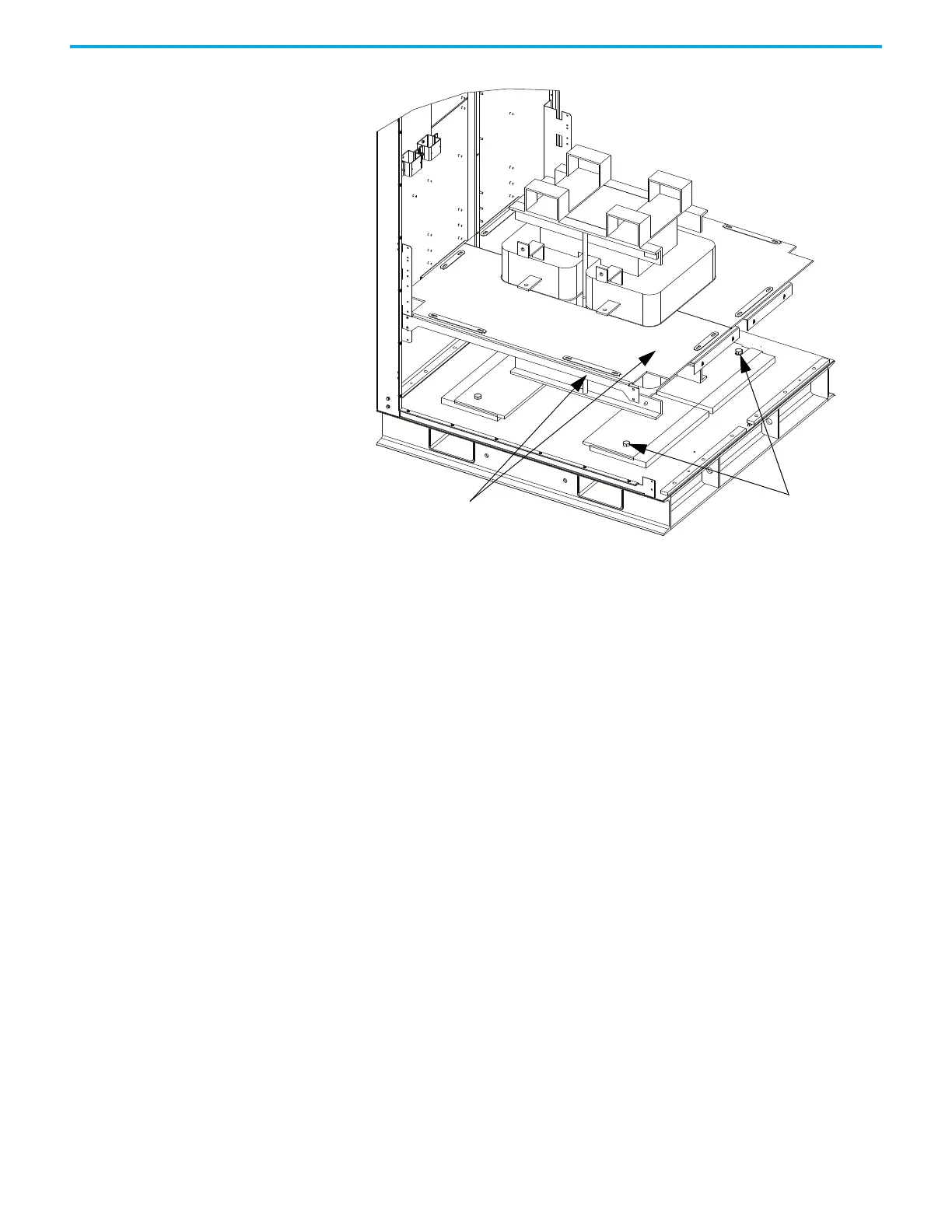

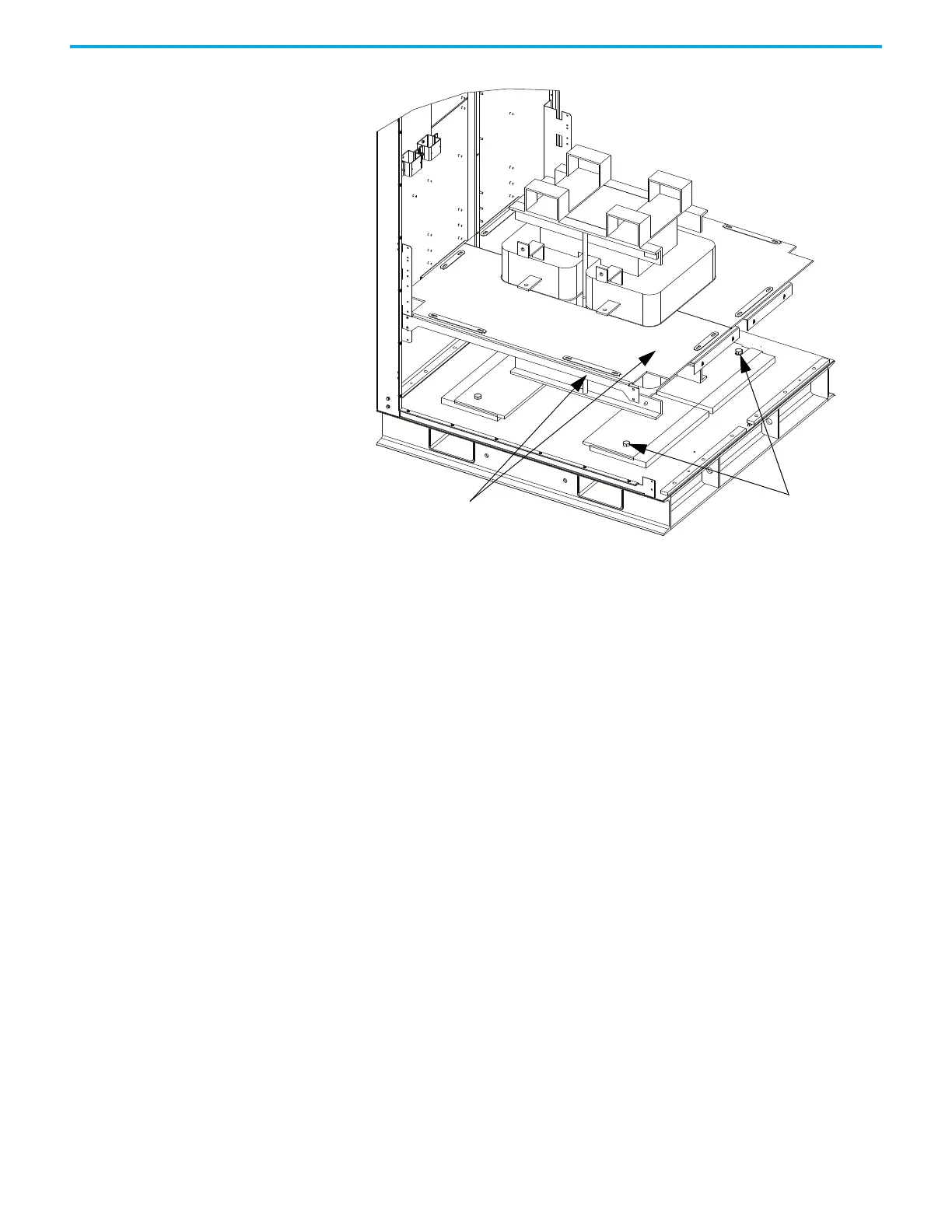

Figure 102 - DC Link Removal (Heatpipe Model)

Install the replacement DC link in the reverse order of its removal.

DC link leads or cable must be routed so that electrical clearances are

maintained and the correct terminals are connected. You must also verify that

the nameplate ratings are the same or appropriate for the drive system. A

different DC link will require different parameter settings.

The DC link maintains a low ripple current between the line converter and the

machine converter. Thermal protection of the DC link reactor is provided by

two normally closed contacts wired to the I/O module. These contacts will open

at 190°C and cause a fault/alarm message to be displayed.

The DC link in a heatpipe cabinet has a large medium voltage door.

Interlocking prevents opening the medium voltage door unless the source

power is locked out.

Fan power must be disconnected using the handle on the right hand side of the

LV door to open the LV compartment.

3. Remove DC

Link hardware

and slide DC Link

forward

1. Remove front DC Link

barrier and front barrier

support brace

Loading...

Loading...