Rockwell Automation Publication 7000-UM202H-EN-P - November 2023 125

Chapter 2 Power Component Definition and Maintenance

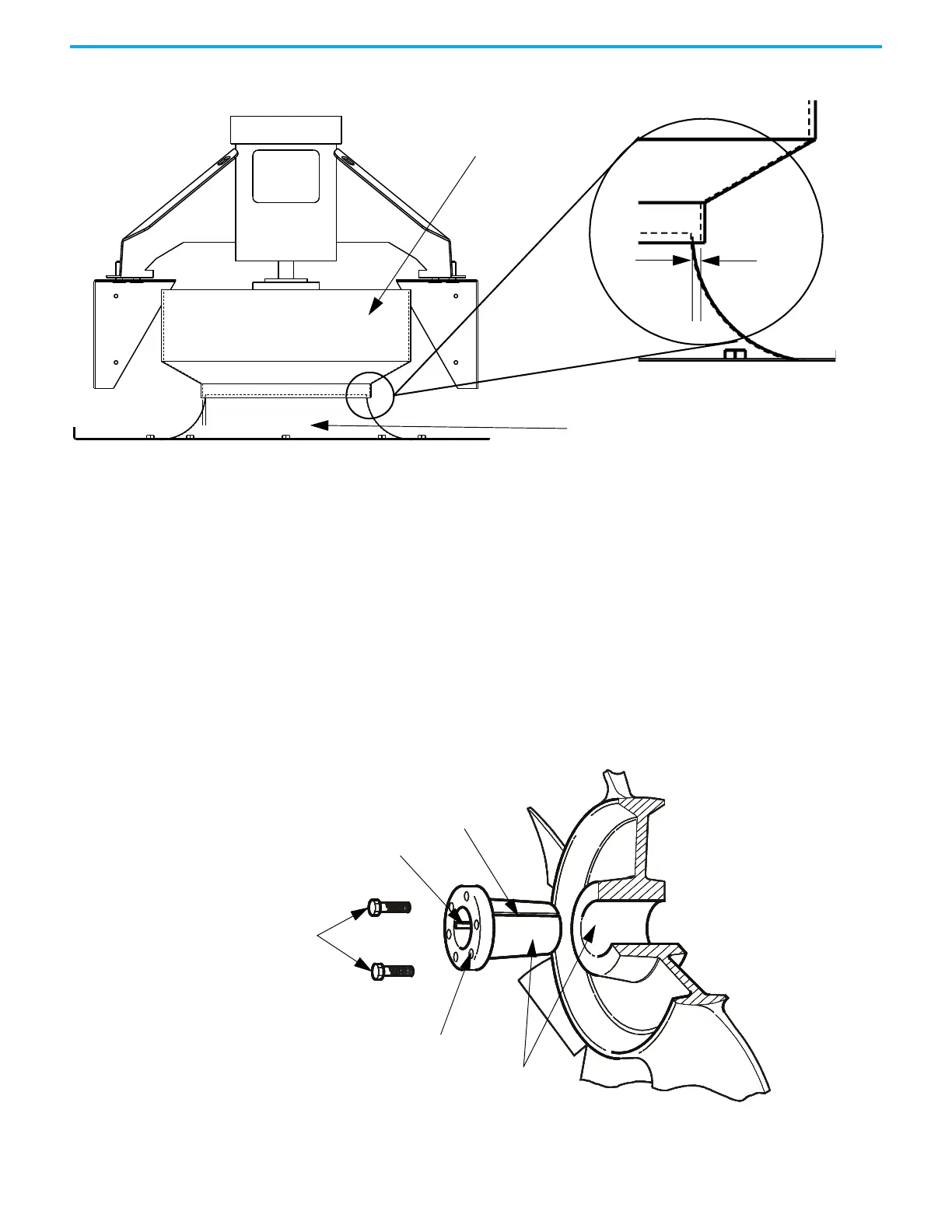

Figure 107 - Fan Assembly Installation

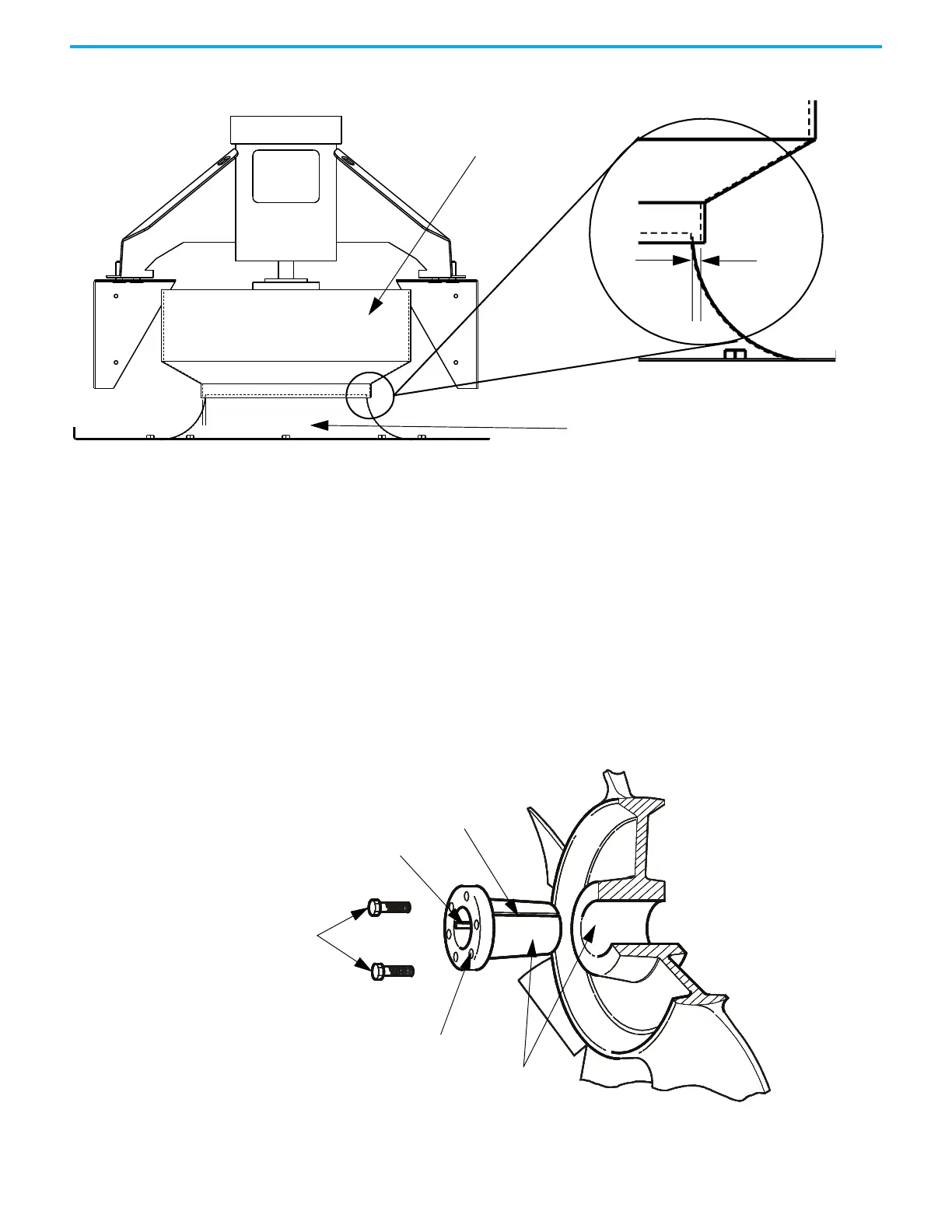

Impeller Maintenance

The fan impeller connects to the motor shaft with a split tapered bushing. This

bushing is positioned on the motor shaft and through the center of the

impeller. Two cap screws, when tightened to 10.2 N•m (7.5 lb•ft), lock the

bushing onto the motor shaft and the impeller to the bushing.

Impeller Removal from Motor Shaft

The impeller is not designed to support the weight of the motor.

If vertical, the impeller and bushing may fall when loosening cap screws.

Physical injury or component damage may result.

Figure 108 - Impeller Removal

1. Record the distance from the end of the motor shaft to the bushing. The

new impeller must be installed in the same location. Failure to do so will

Outer Fan Shroud

Inlet Ring

Gap MUST

be 6.3 mm

(0.25 in.) on

both sides

Cap Screws

Threaded Hole for

Separating Tapers

Key

Split in Taper Bushing

Taper Surfaces

Loading...

Loading...