119MS 261, MS 261 C

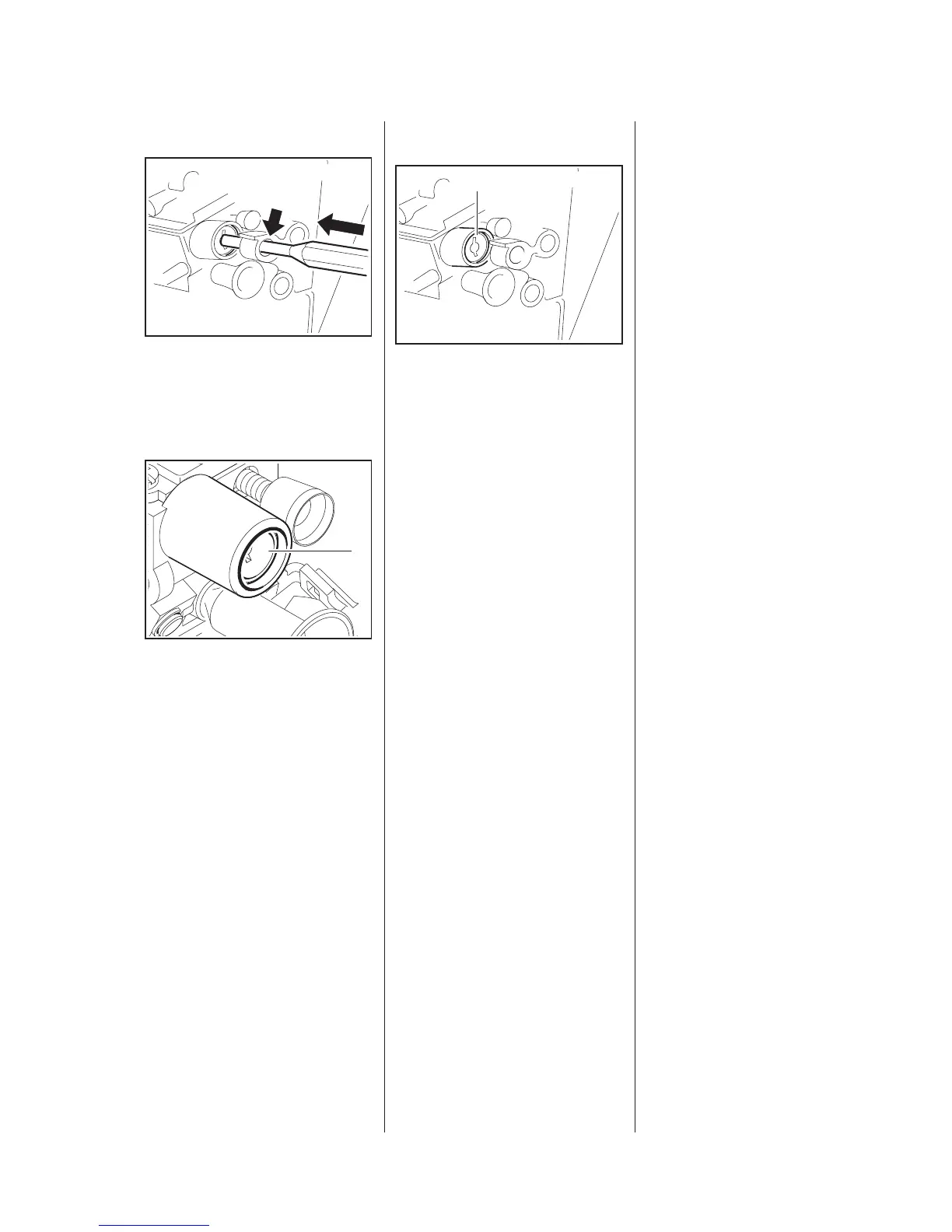

Securing the limiter cap

: Insert a drift through the

opening (arrow) and then push

home the limiter cap until it

engages.

This completes the basic setting of

the high speed screw (H) and the

low speed screw (L).

The setting of the high speed

screw (H) is fixed when the limiter

cap (1) is recessed 2mm in the

carburetor body.

5902RA415 TG

5902RA416 TG

1

12.7.2 Standard setting

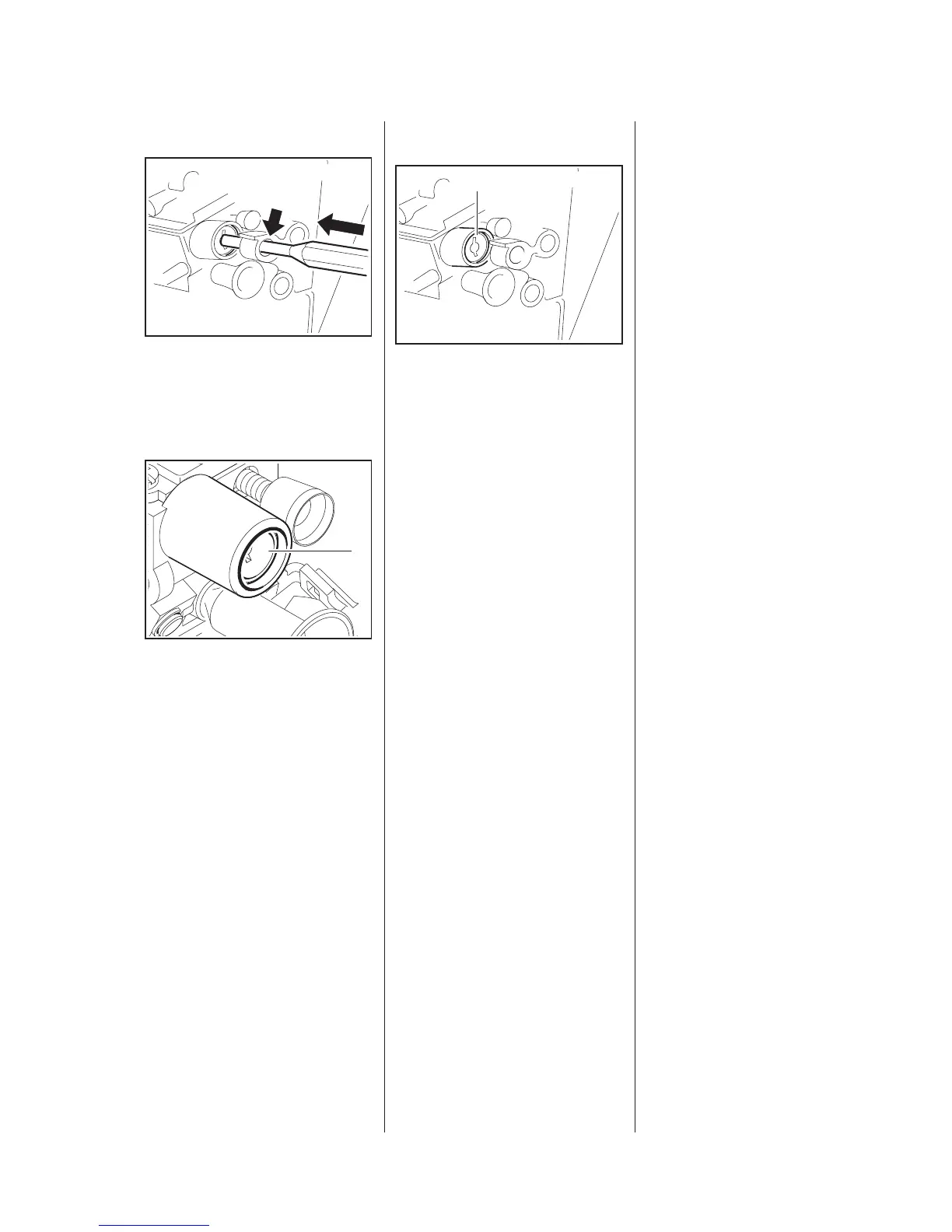

The limiter cap (1) must not be

removed for the standard setting.

Always perform the following steps

before carrying out any

adjustments:

– Troubleshooting, b

12.1

Standard setting

– Shut off the engine.

– Turn the high speed screw (H)

slowly counterclockwise as far as

stop, but not more than

a 3/4 turn.

– Turn the low speed screw (L)

slowly clockwise as far as stop,

then turn it back 1 full turn.

5902RA394 TG

1

Check running behavior:

The engine must idle and

accelerate smoothly.

Adjusting engine idle speed

– Carry out standard setting.

– Warm up the engine.

Engine stops while idling

– Turn the idle speed screw (LA)

clockwise until the chain begins

to run, then turn it back 1 full turn.

Saw chain runs while engine is

idling

– Turn the idle speed screw (LA

) counterclockwise until the chain

stops running, then turn it back

1full turn.

Erratic idling behavior, poor

acceleration

(although standard setting is

correct)

Idle setting too lean.

– Warm up the engine.

– Turn low speed screw (L)

counterclockwise until the engine

runs and accelerates smoothly.

It is usually necessary to change the

setting of the idle speed screw (LA)

after every correction to the low

speed screw (L).

Loading...

Loading...