133MS 261, MS 261 C

13.3 Handle Heating System

13.3.1 Troubleshooting

The entire handle heating system is

maintenance-free and subject to

practically no wear. Faults in the

generator, heating elements and

wiring are generally caused by

mechanical damage.

There are two reasons for failures in

the heating system:

1. A break in the

circuit due to a

faulty wire or

component.

2. A short circuit

resulting from damage to the

insulation.

– Remove the handle molding,

10.2

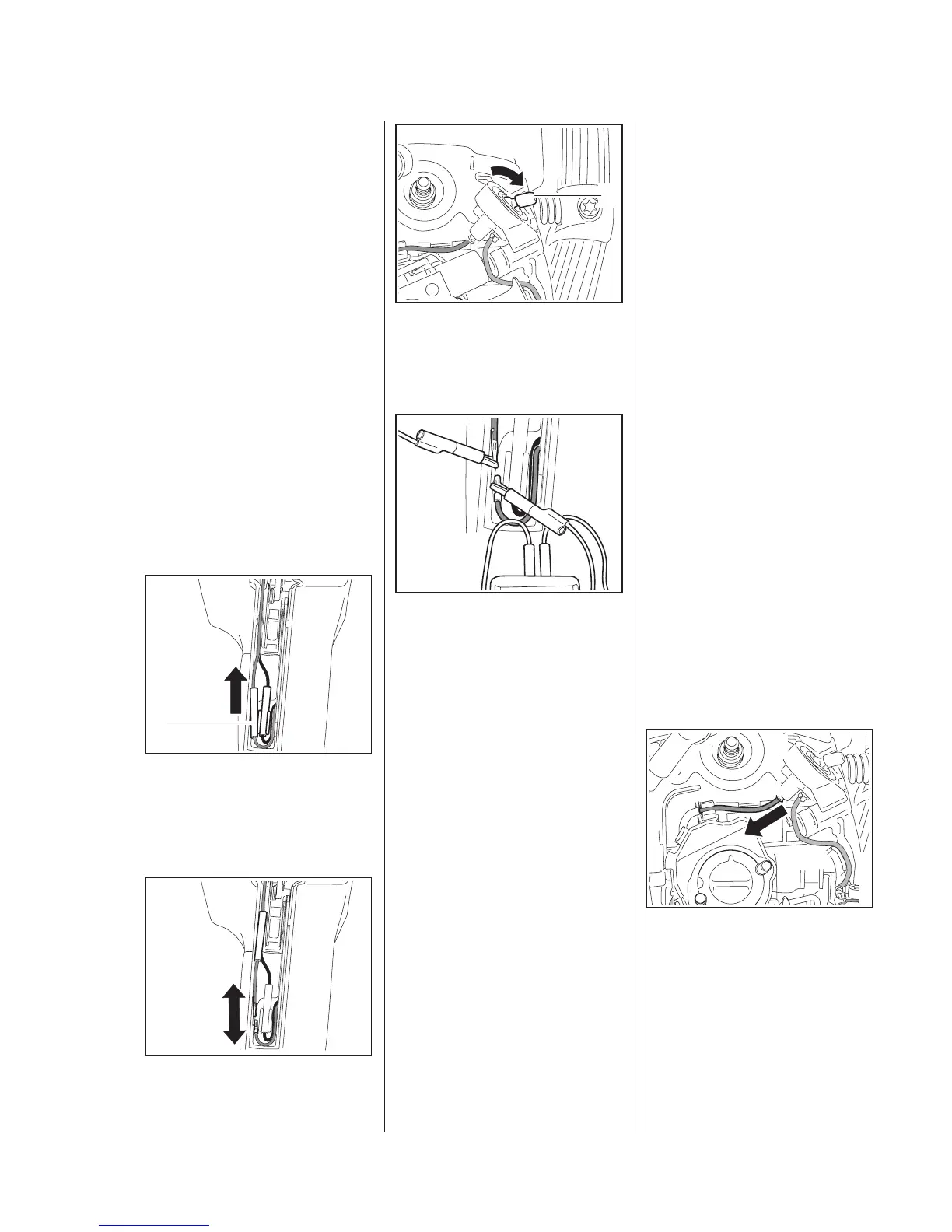

: Pull one of the connectors out of

the guide and push the insulating

tube (1) in the direction of the

wiring harness.

: Separate the pin and socket

connector.

5902RA518 TG

1

5902RA519 TG

: Set the heater switch (1) to "F".

– Set the ohmmeter to "Ω".

– Set the Master Control lever to

"

0".

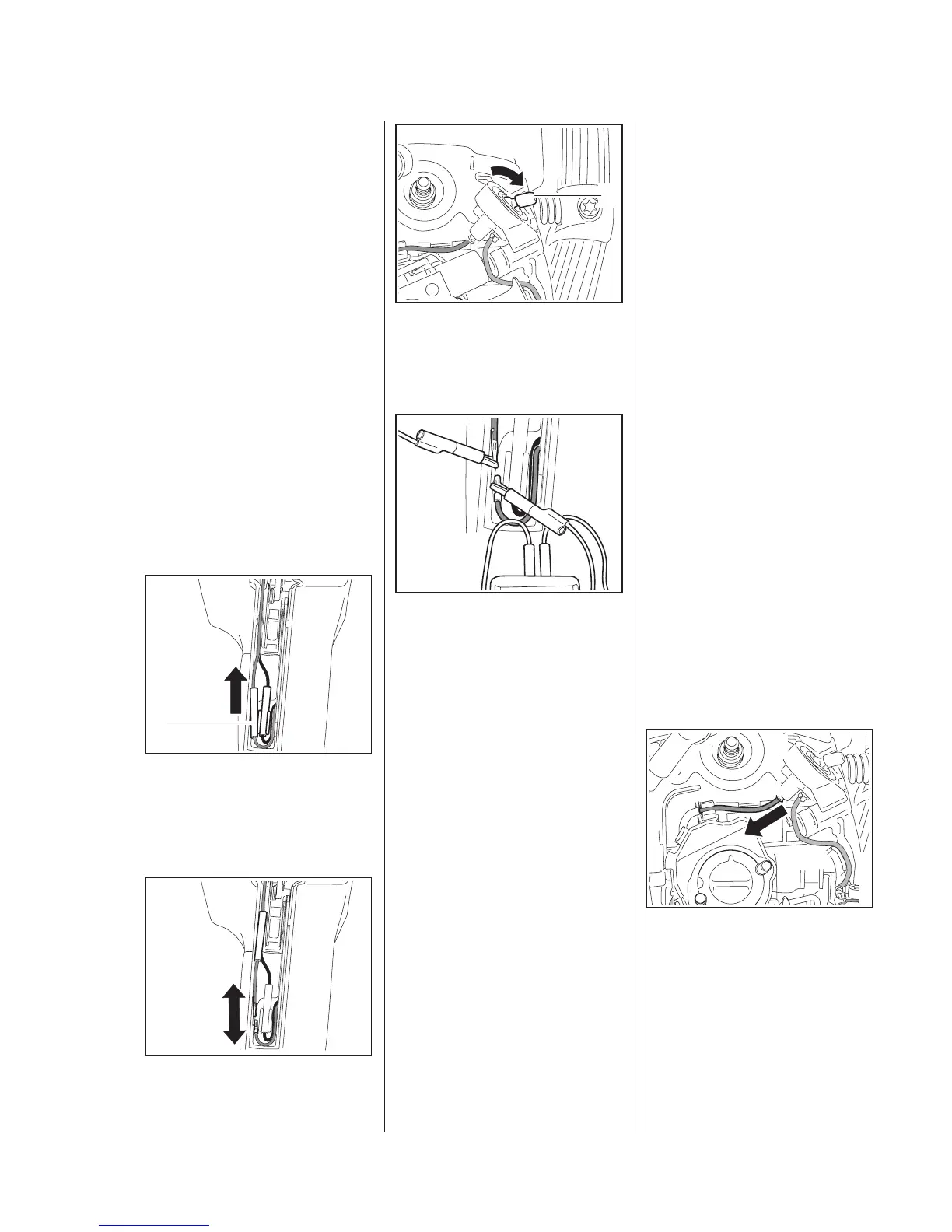

: Clip the test leads to the wire

from the wiring harness and the

rear handle heating element wire.

Carburetor Heating

– Separate the pin and socket

connector to the thermostatic

switch, b

13.1.3

All electrical components of the

handle heating system are

connected in series with the

ohmmeter.

If the system is in order, the

ohmmeter will indicate a value of

about 10 Ω in measuring range "Ω".

If no reading is obtained, there is a

break in the circuit.

5902RA573 TG

1

5902RA574 TG

If the ohmmeter shows a very low

value, there is a short circuit in one

of the components.

In either case it is necessary to

check each component separately.

The generator wire remains

disconnected from the thermostatic

switch during this check.

– Use handle heating and

generator troubleshooting chart

to check the system, b

13.7.1

– Check resistance on handlebar,

13.6

– Check resistance on rear handle,

13.5

– After completing the test,

reconnect the wires and push the

insulating tube over the pin and

socket connector.

– Reassemble in the reverse

sequence.

13.4 Heater Switch

– Remove the carburetor,

12.5

: Pull off the connector sleeve (1).

5902RA575 TG

1

Loading...

Loading...