8-12 POWER TRIM AND TILT

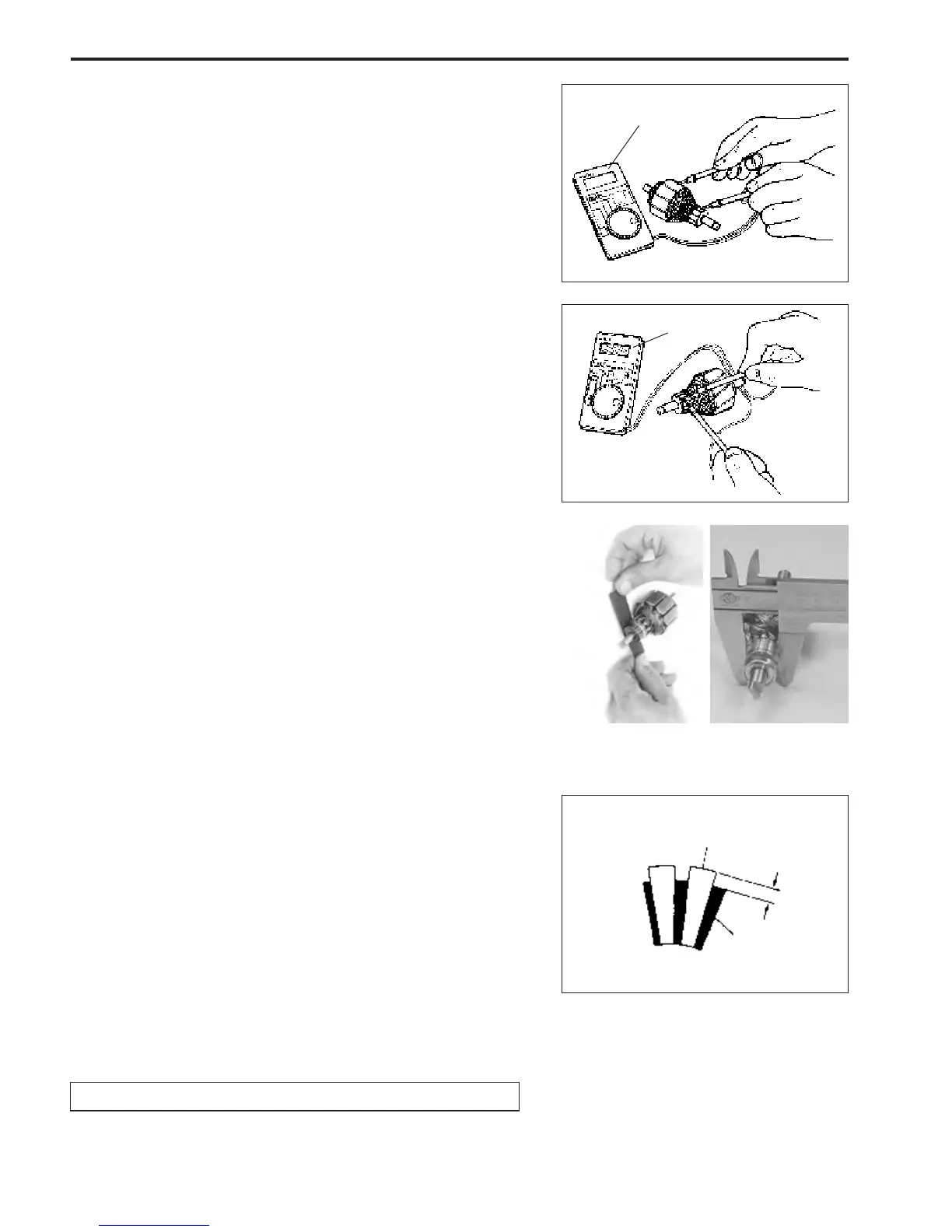

PTT MOTOR INSPECTION

Armature and Commutator

1. Inspect continuity between commutator and armature

core / shaft.

If continuity exists, replace armature.

\ 09930-99320 : Digital tester

T Tester range :

@@

@@

@ (Continuity)

2. Inspect continuity between adjacent commutator segments.

If no continuity exists, replace armature.

3. Inspect commutator surface for gum or dirt.

Clean with #500 grit emery paper if necessary.

Measure commutator outside diameter.

\ 09900-20101 : Vernier calipers

Commutator outside diameter :

Standard : 22.0 mm (0.87 in.)

Service limit : 21.0 mm (0.83 in.)

If measurement exceeds service limit, replace armature.

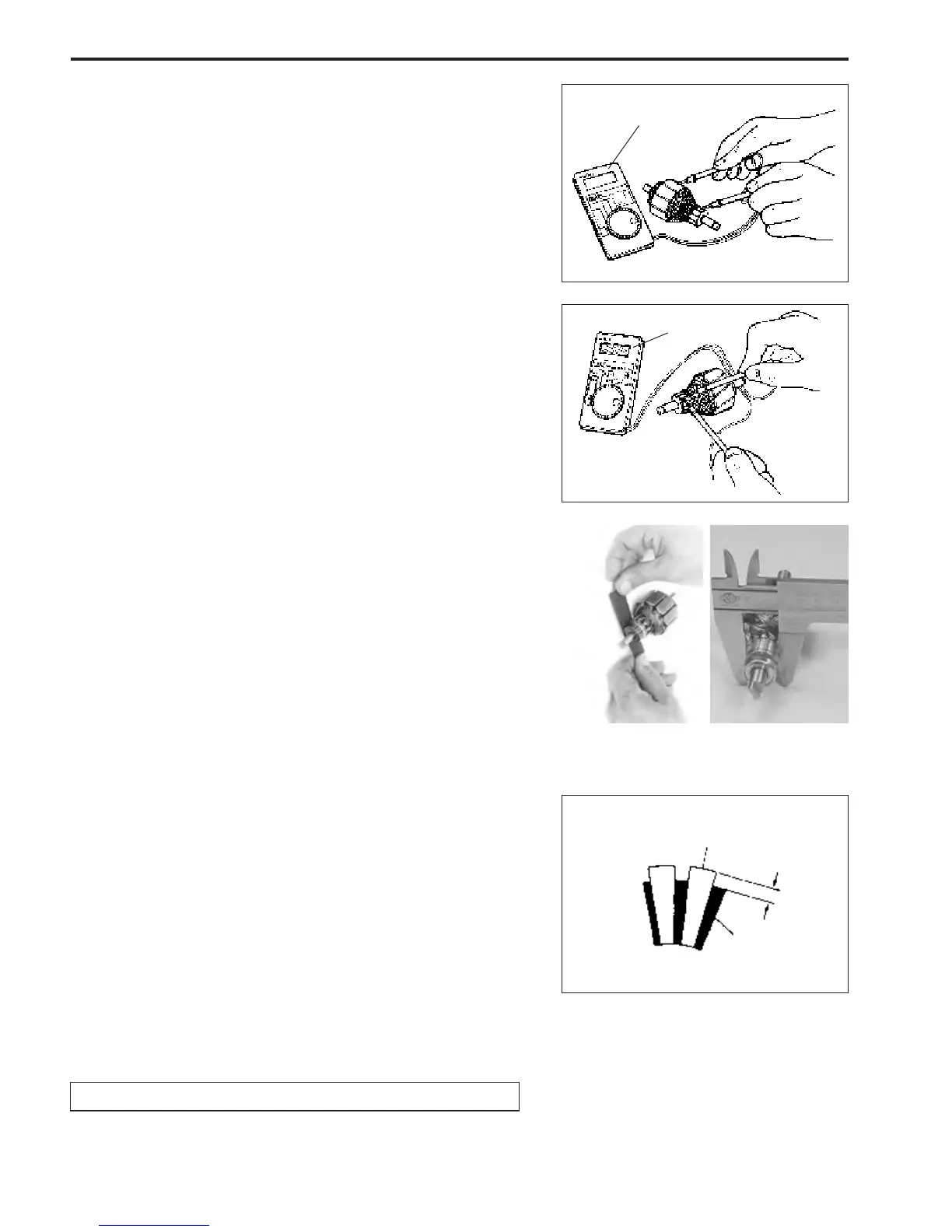

4. Measure commutator undercut (depth) between mica

(insulator) and segments.

Commutator undercut

11

11

1 (depth) :

Standard : 1.6 – 1.9 mm (0.06 – 0.07 in.)

Service limit : 1.3 mm (0.05 in.)

If measurement exceeds service limit, cut mica to specified

depth.

NOTE:

Remove all particles of mica and metal using compressed air.

#

Wear safety grasses when using compressed air.

SEGMENT

MICA

1

1 Commutator undercut

\

\

Loading...

Loading...