PERIODIC MAINTENANCE 2-9

TAPPET CLEARANCE

Inspect initially after 20 hours (1 month) and every 200

hours (12 months).

The tappet clearance specification is the same for both intake

and exhaust valves.

Too small a tappet clearance may reduce engine power, too

large a tappet clearance increases valve noise and hastens

valve and seat wear.

When the tappets are set to the specified clearance, the en-

gine will run without excessive noise from the valve mecha-

nism and will deliver full power. In this engine, the tappet clear-

ance is increased or decreased by replacing the shim disc,

made of a special wear resistant material, fitted to the top of

the tappet.

The shim discs are easy to remove and refit.

Tappet clearance adjustment should be checked and adjusted :

• at time of periodic inspection

• when valve mechanism is serviced

• when camshafts are disturbed by removing them for inspec-

tion

CHECKING AND ADJUSTING TAPPET CLEARANCE

1. Remove following parts :

• Engine side covers (see page 7-2)

• Flywheel cover

• Spark plugs

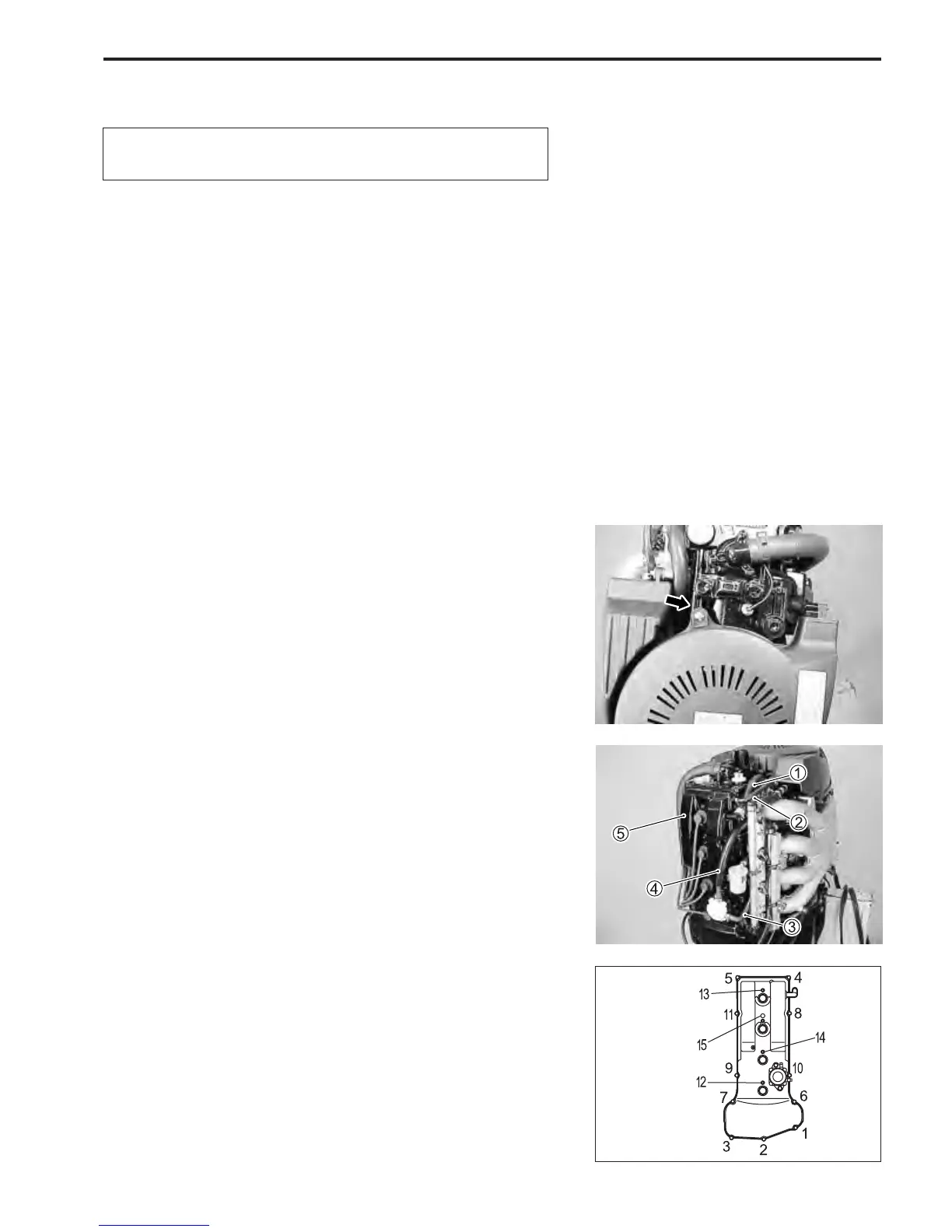

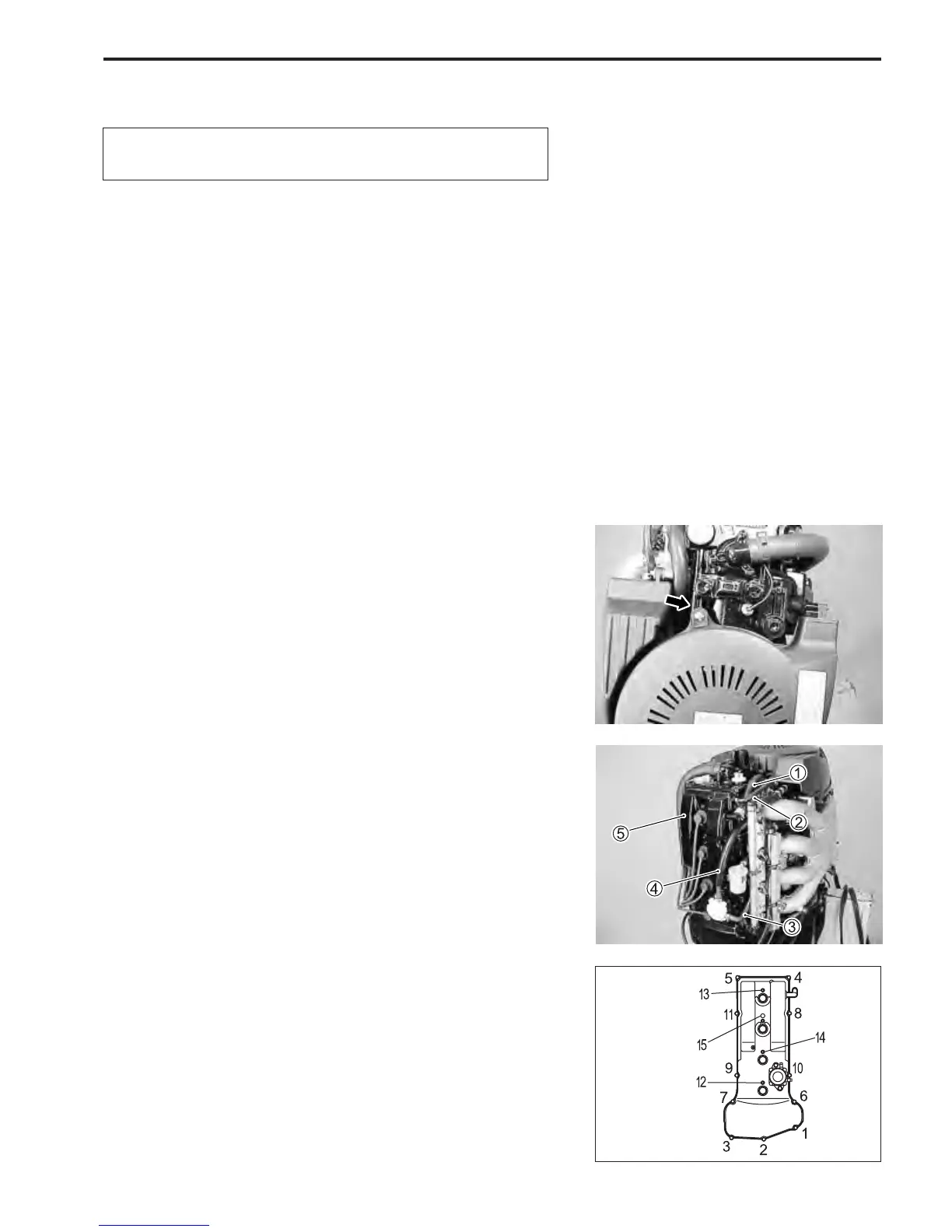

2. Remove breather hose 1 and evaporation hose 2 from

cylinder head cover.

3. Remove fuel hose 3 and 4 from low pressure fuel pump.

4. Remove fifteen (15) bolts securing cylinder head cover 5

to cylinder head and remove cylinder head cover.

Loosening

order

Loading...

Loading...