3-14 ENGINE CONTROL SYSTEM

ELECTRONIC FUEL INJECTION SYSTEM

The fuel injection system used by the DF90/DF115 is a speed-density, multi-point, sequential, electronic fuel

injection type.

The fuel injection system is composed of the fuel line components, air intake components, and components

for system control (ECM, sensors, switches, etc.).

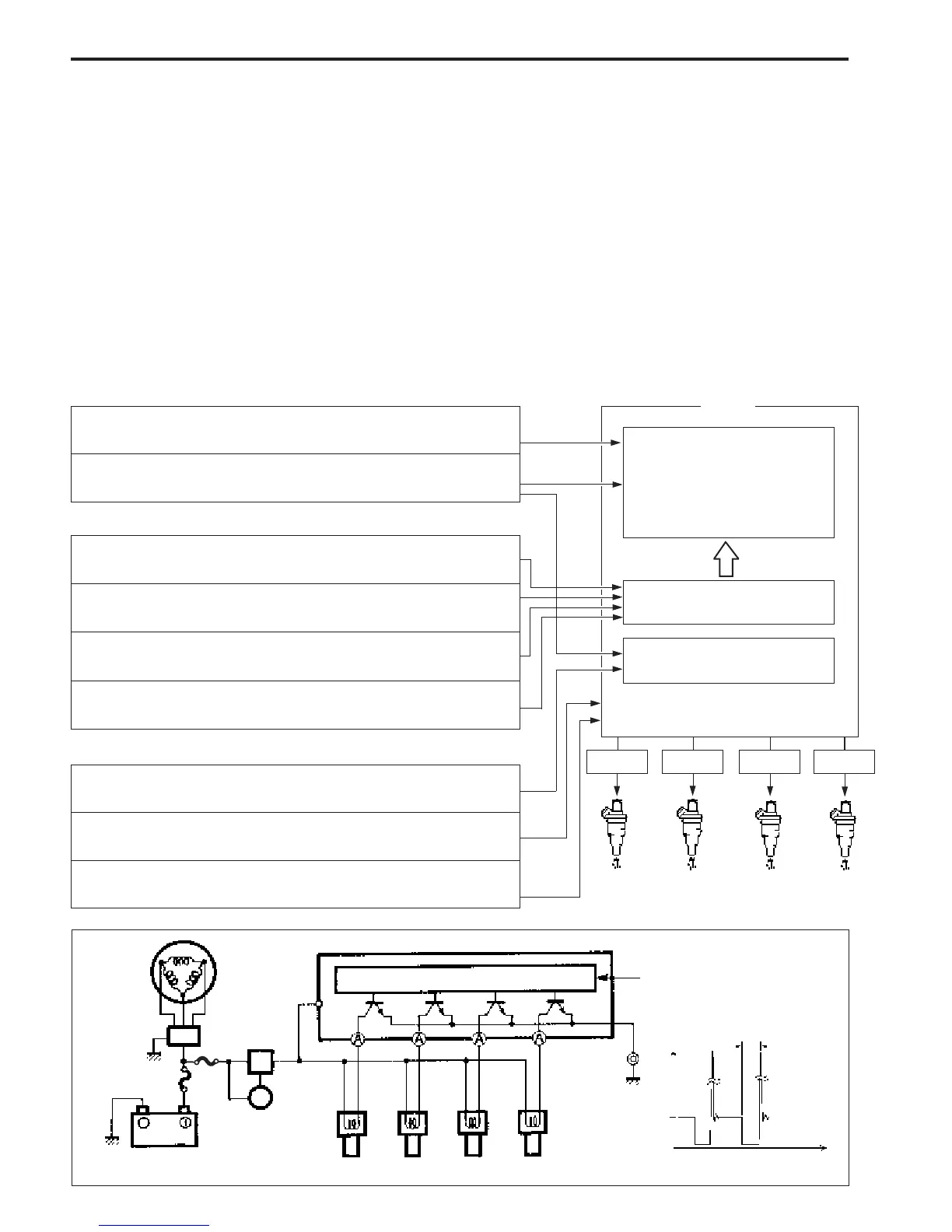

FUEL INJECTION CONTROL SYSTEM

OUTLINE

Sensors are mounted at precise locations on the motor to monitor the current conditions of engine operation

and send signals to the ECM. Based on these signals, the ECM determines the optimum fuel injection time

duration (fuel amount), fuel injection timing (multi-point sequential timing) and controls the injector operating

signals accordingly.

Fuel injection start timing is set at BTDC445° on exhaust stroke constant.

ECM

CPU

Sensor / switch

signal input

Injector

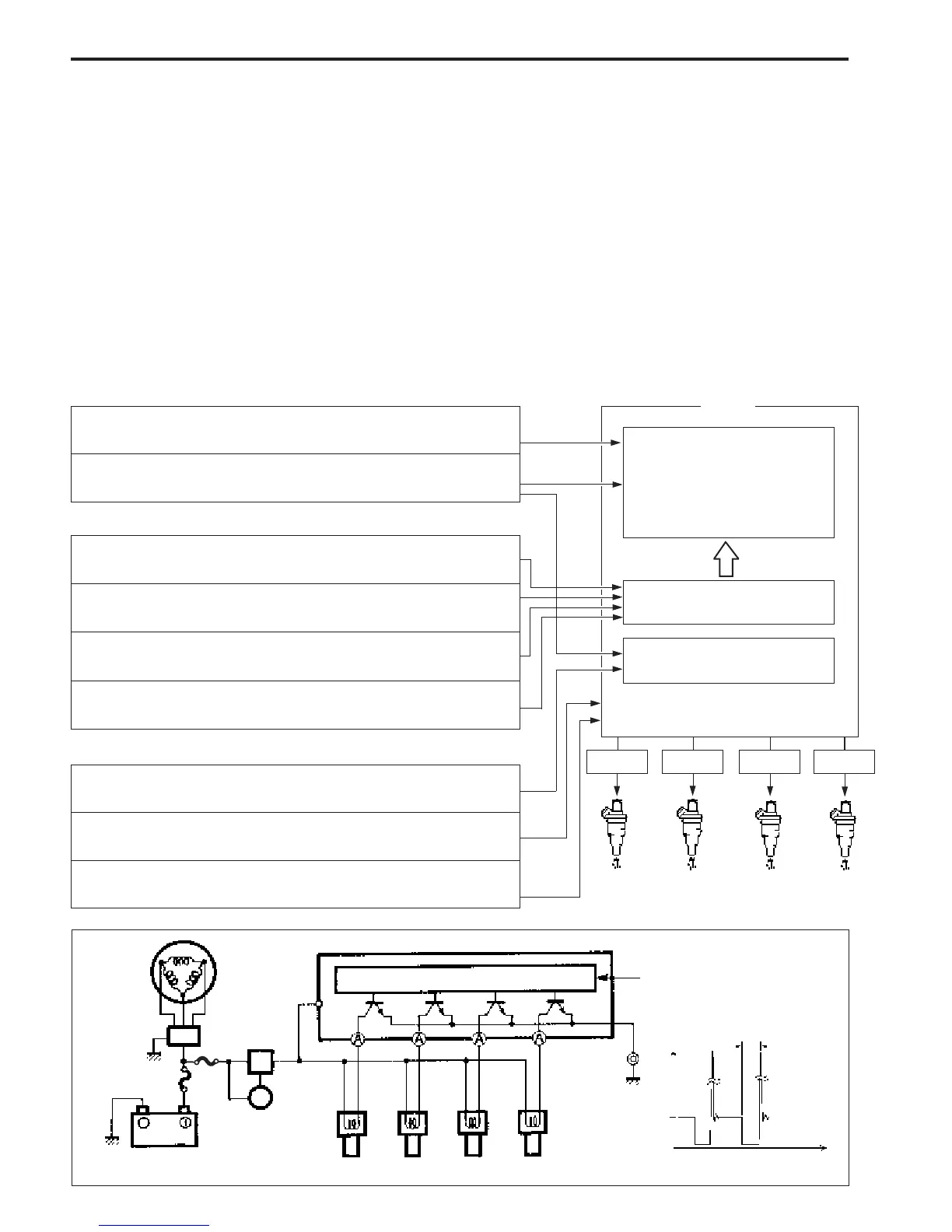

Ignition

switch

Battery

60A fuse

Rectifier &

regulator

Battery

charge

coil

ECM

main

relay

30A fuse

(Voltage)

Injection time

duration

12V

A terminal voltage

(Time)

Basic sensors

Compensating sensors

Injector

MAP sensor :

Informs ECM of intake manifold pressure.

CKP sensor :

Informs ECM of engine speed and crankshaft angle.

Cylinder temperature sensor :

Informs ECM of cylinder temperature.

Fuel injection time duration

(amount) is determined by

a digital map designed in

relation to intake manifold

pressure and engine speed.

Fuel amount compensation

Others

CMP sensor :

Informs ECM of camshaft angle.

CTP switch :

Informs ECM of throttle position (open / closed).

IAT sensor :

Informs ECM of intake air temperature.

MAP sensor :

Informs ECM of barometric pressure at time of engine starting.

Battery voltage :

Constantly monitored by the ECM.

Multi-point sequential timing

Signal Signal Signal

Neutral switch :

Informs ECM of shift position (Neutral or in gear).

Signal

ECM

Loading...

Loading...