11-30 DF140 “K2” (’02) MODEL

Inspect tilt rod and trim rod, replace if damaged or bent.

Inspect the surface of tilt rod and trim rod for scores, grooves or

roughness.

Slight roughness may be removed with fine emery paper.

A badly scored or grooved rod must be replaced.

Inspect the PTT cap seal and O-ring.

Replace if cuts, nicks, or excessive wear is found.

NOTE:

It is recommended that the O-ring always be replaced once the

tilt/trim cylinder has been disassembled.

Inspect the shock valves (spring, rod and ball).

Replace if there are any signs of rust or pitting.

Inspect the cylinder bore for evidence of a rough or grooved

surface.

Light honing may rectify slight surface roughness or scarring,

but a deeply scarred surface will require replacement of the tilt

cylinder.

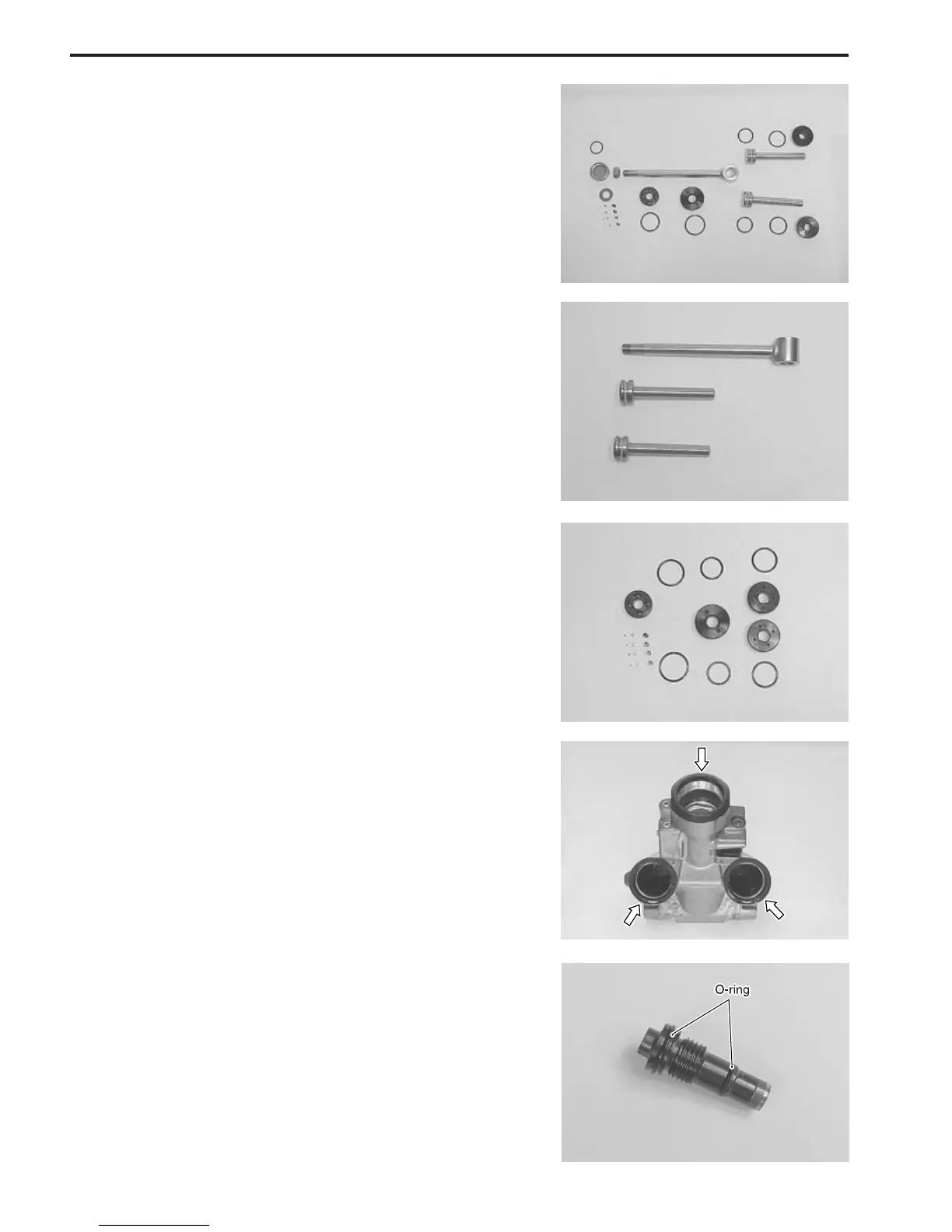

Inspect manual release valve for damage.

Inspect manual release valve O-ring.

Replace if nicked or cut.

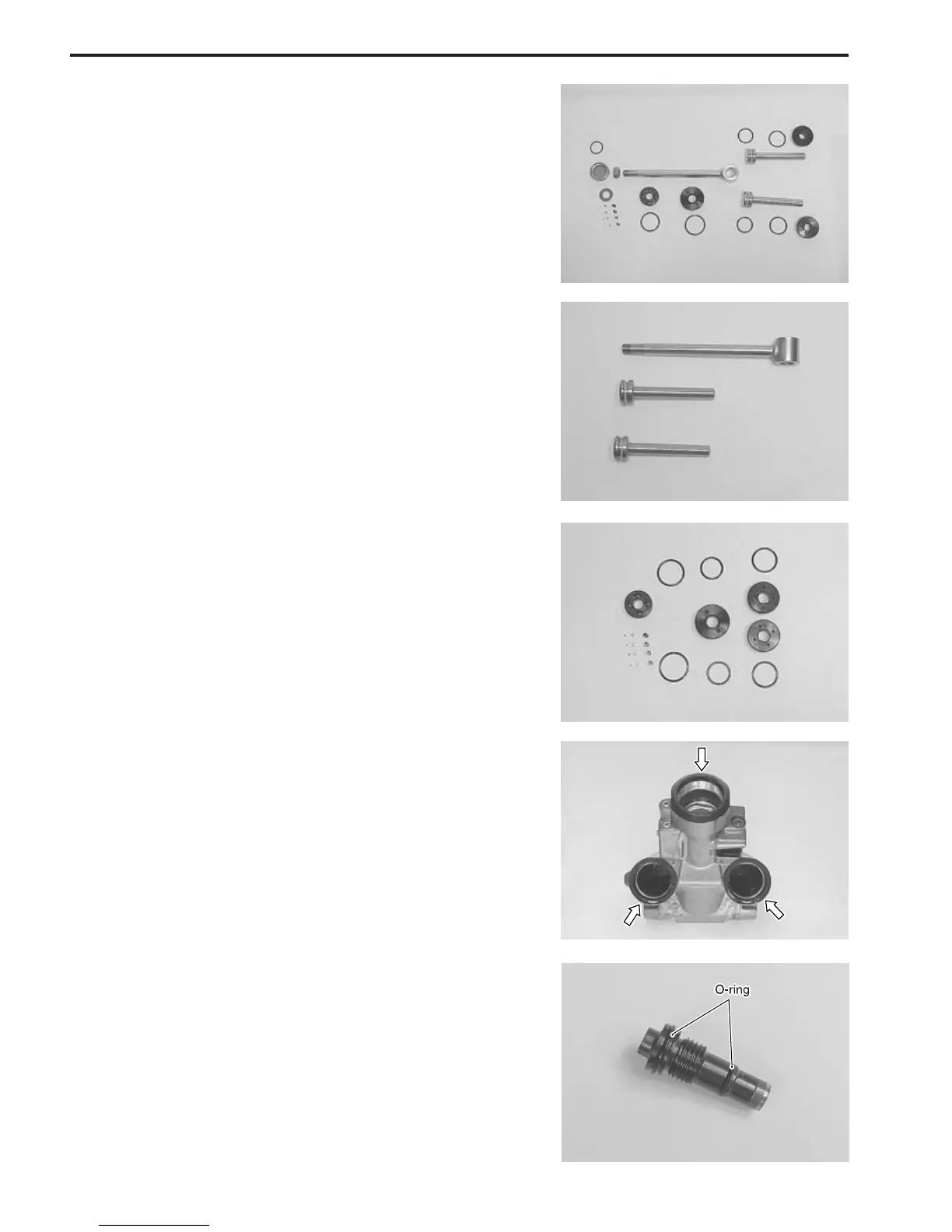

CLEANING AND INSPECTING

Thoroughly wash all metal components with cleaning solvent

and dry them with compressed air.

Arrange all components on a clean sheet of paper.

NOTE:

Do not lay PTT components out on a rag, as dirt or lint may be

transferred to these items which may cause possible system

operating problems.

Loading...

Loading...