DRIVE TRAIN 4-19

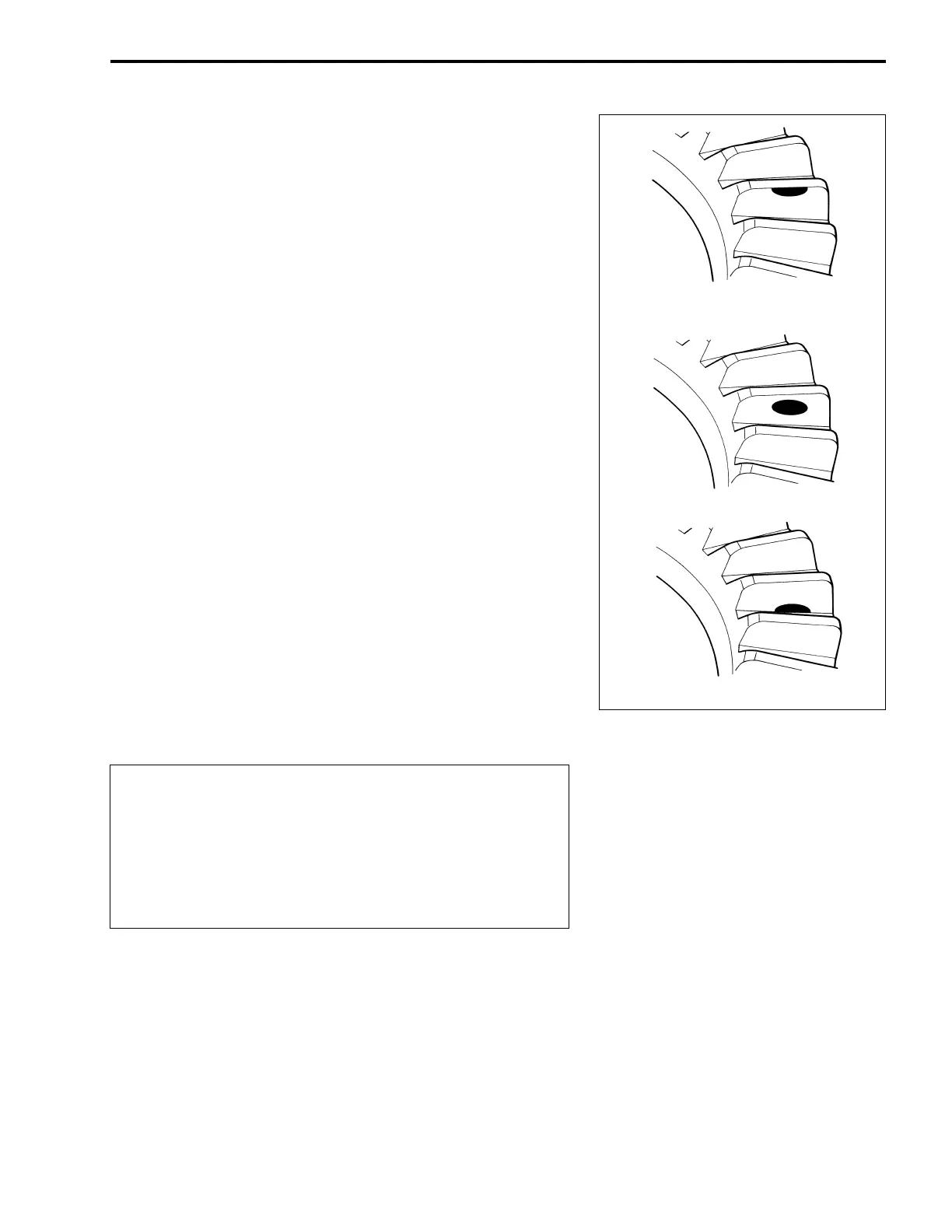

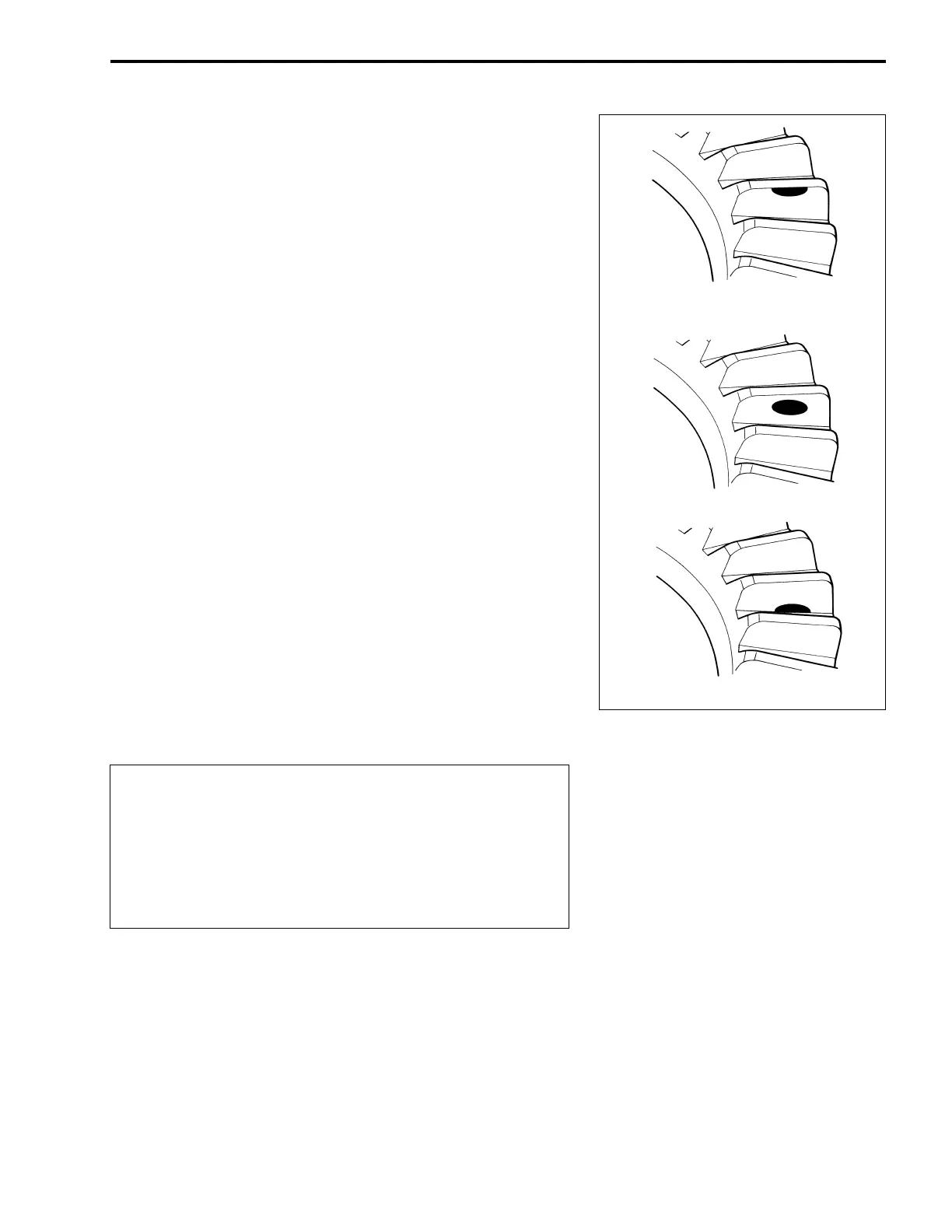

TOOTH CONTACT

After backlash adjustment and left side shim selection are car-

ried out, the tooth contact must be checked. Pay attention to the

following points:

• Remove the differential ring gear.

• Clean and degrease several teeth on the ring gear and pinion

gear, and then apply a coating of machinist’s layout dye or

paste to several teeth of the pinion gear.

• Install the removed left and right side shims and differential

assembly.

• Assemble the gear case cover. (!4-14)

NOTE:

* Do not apply a sealant to the mating surface of the gear case.

* Do not apply a thread lock to the case cover bolts.

(!4-14)

( Gear case cover bolt: 23 N·m (2.3 kgf-m, 16.5 lb-ft)

• Rotate the differential ring gear several turns in each direc-

tion. This will provide a contact pattern on the coated teeth of

ring gear.

• Remove the differential ring gear and compare the coated

teeth to the examples shown in

1,

2 and

3.

• If tooth contact is found to be correct (example

2), go to the

FINAL ASSEMBLY sub-section on p.4-14 to complete instal-

lation.

• If tooth contact is found to be incorrect (example

1 and

3),

the shim must be changed and the tooth contact should be re-

checked until correct.

"

Make sure to check the backlash and shim thickness

after the tooth contact has been adjusted, since it may

have changed. Adjust the tooth contact and backlash

until they are both within specification. If the correct

tooth contact cannot be maintained when adjusting

the backlash, replace the pinion gear and ring gear as

a set.

Incorrect (Contact at tooth top)

Incorrect (Contact at tooth root)

Correct

Loading...

Loading...