97

Absolute value control = maintaining a sensor

S1 can be kept at one temperature (such as 50°C) very well by using the speed control. If

the solar radiation is reduced, S1 becomes colder. The control unit then lowers the speed

and hence the flow rate. However, that causes the warm-up time of the heat transfer medium

in the collector to increase, thus increasing S1 again.

A constant return (S2) may make sense as an alternative in various systems (such as

boiler feeds). Inverse control characteristics are necessary for this. If S2 increases, the heat

exchanger does not provide enough energy to the cylinder. The flow rate will then be

reduced. The longer dwell time in the exchanger cools the heat transfer medium more, thus

reducing S2. It does not make sense to keep S3 constant as the variation in the flow rate

does not directly affect S3; hence, no regulator circuit will result.

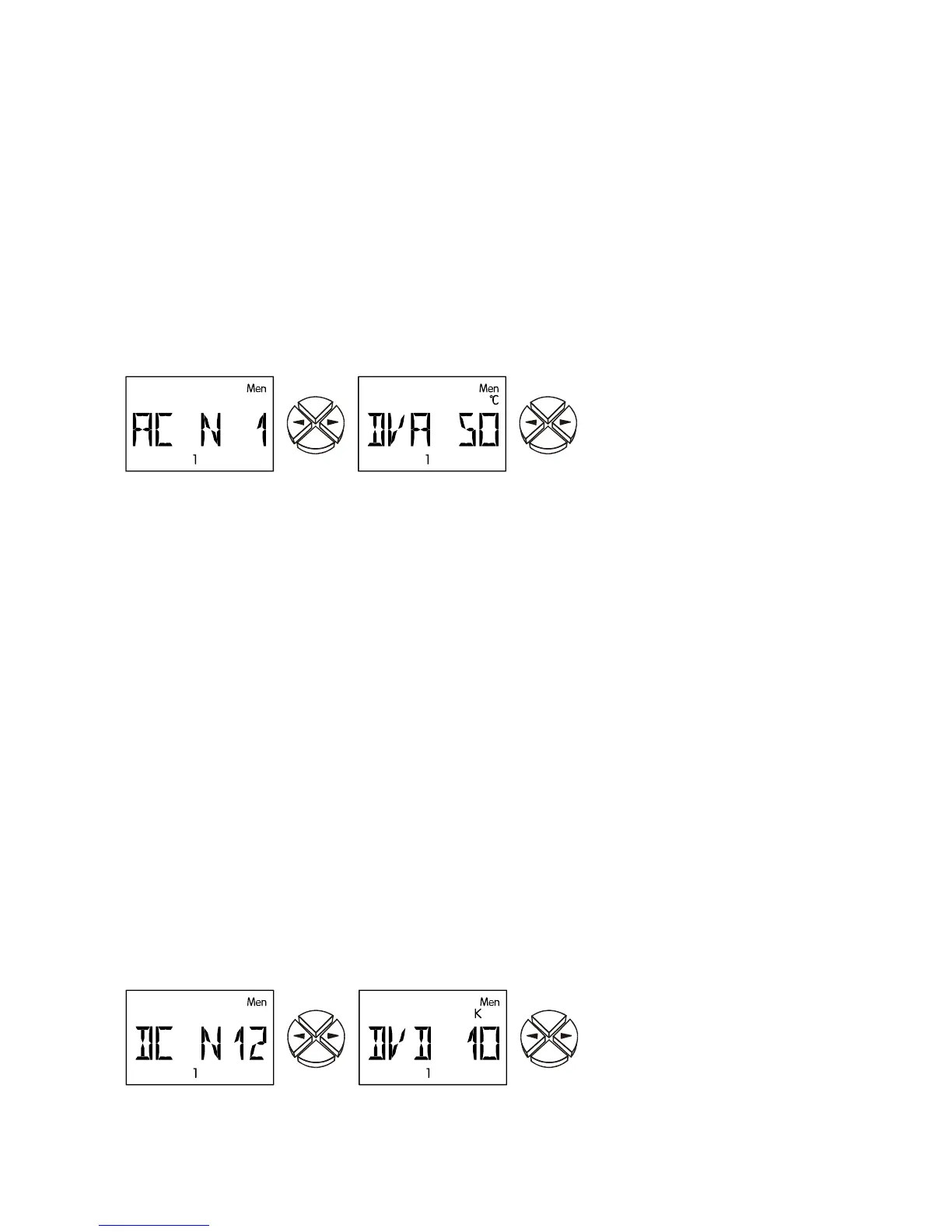

The absolute control is set via two parameter windows. The

example has typical settings

for the hydraulics:

AC N 1 Absolute value control in normal operation, with sensor S1 being kept constant.

Normal operation N means that the speed increases as temperatures do and is

valid for all applications to keep a “feed sensor” constant (collector, boiler, etc.)

Inverse operation I means that the speed decreases as temperatures drop and

is necessary to maintain a return or control the temperature of a heat exchange

outlet via a primary circulating pump (such as hygienic hot water). If the

temperature at the heat exchanger’s outlet is too high, too much energy yield

enters the heat exchanger, thus reducing the speed and hence the input. (ex

works = --)

Setting range: AC N 1 to AC N6, AC I 1 to AC I 6

AC -- = absolute value control is disabled.

DVA 50 The desired value for absolute value control is 50°C. In the example, S1 is thus

kept at 50°C. (ex works = 50°C)

Setting range: 0 to 99°C in increments of 1°C

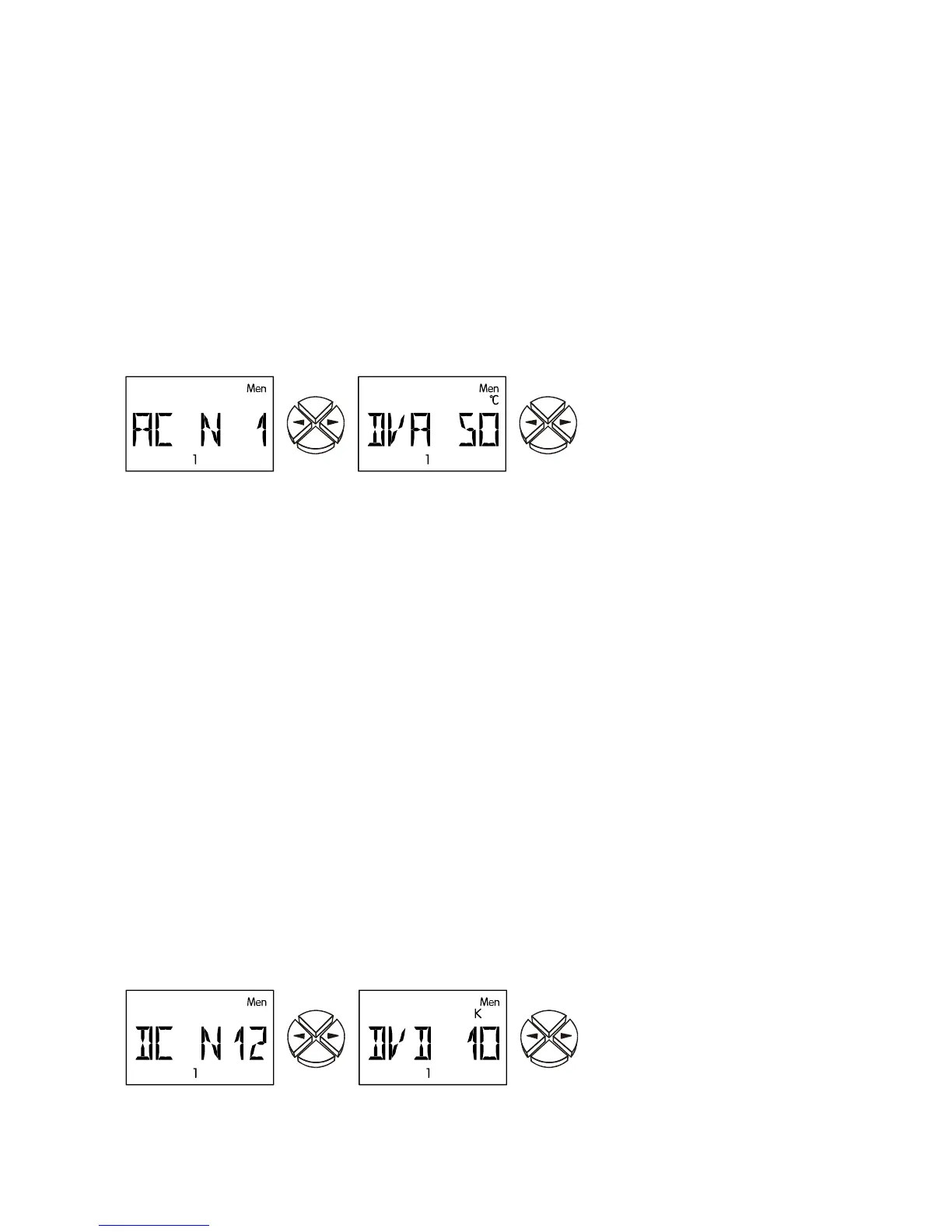

Differential control = keeps the temperature constant between two sensors.

Keeping the temperature difference constant between S1 and S2, for instance, allow for

“shifting” operation of the collector. If S1 drops due to lower irradiation, the difference

between S1 and S2 thus drops. The control unit then lowers the speed, which increases the

dwell time of the medium in the collector and hence the difference between S1 and S2.

Example:

Loading...

Loading...