Calibration-PS

501

0

Performance Check Procedure

c.

Press the following buttons in the order listed:

SUPPLY SELECT

POS

5

ENTER

CURRENT

4

6

ENTER

d. Turn the OUTPUT

ON.

e. Note the dvrn reading

(4.990

V to

5.01 0

V).

f. Turn the OUTPUT OFF.

g.

Connect the

5

52

resistor from the front panel POSITIVE

terminal to the front panel common terminal.

h. Turn the OUTPUT

ON.

i.

CHECK-the dvrn for a reading.of

=GI0

mV from the

reading noted in step e.

To prevent resistor overheating do not leave the resis-

tor connected for longer than necessary to make the

check.

Repeat steps a through i for the NEGATIVE supply.

Substitute the word NEGATIVE for POSlTlVE in these

steps. All tolerances and voltages are identical except

for the sign change.

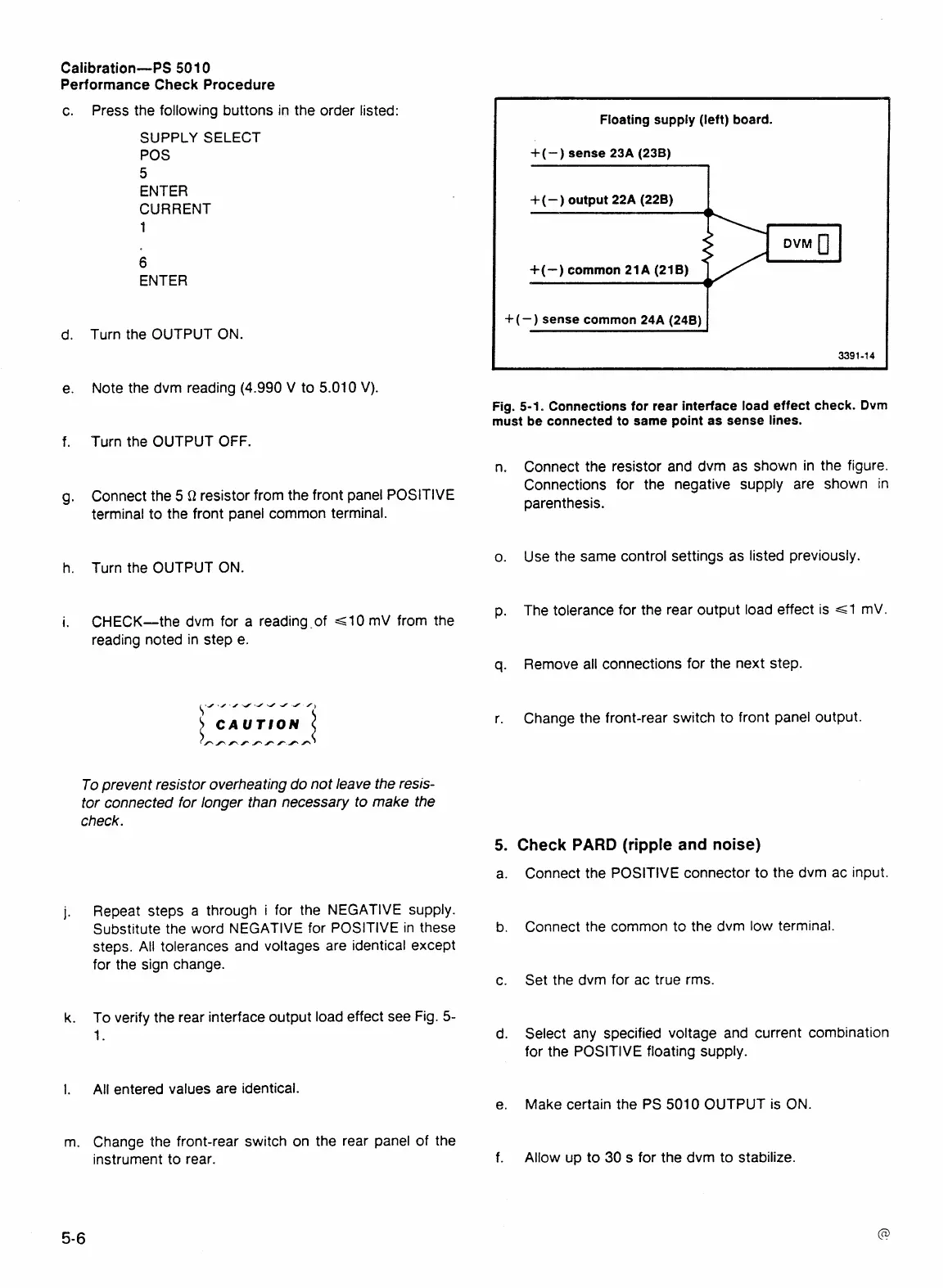

To verify the rear interface output load effect see Fig.

5-

1.

All entered values are identical.

m. Change the front-rear switch on the rear panel of the

instrument to rear.

Floating supply (left) board.

+

(

-

)

sense

23A (238)

I

+

(

-

)

output

22A

(228)

+(-)

common

21A (218)

7-

+

(-)

sense common

24A (2481

1

Fig.

5-1.

Connections for rear interface load effect check.

Dvm

must be connected to same point as sense lines.

n.

Connect the resistor and dvrn as shown in the figure.

Connections for the negative supply

are shown

in

parenthesis.

o.

Use the same control settings as listed previously.

p.

The tolerance for the rear output load effect is

=GI

mV.

q.

Remove all connections for the next step.

r.

Change the front-rear switch to front panel output.

5.

Check

PARD

(ripple

and noise)

a.

Connect the POSITIVE connector to the dvrn ac input.

b.

Connect the common to the dvrn low terminal.

c. Set the dvrn for ac true rms.

d. Select any specified voltage and current combination

for the POSITIVE floating supply.

e.

Make certain the PS

SO1 0

OUTPUT is ON.

f.

Allow up to

30

s

for the dvrn to stabilize.

Loading...

Loading...