Safety

MAINTENANCE

AND

STORAGE

1. When equipment

is

stopped for

servicing, inspection, storage, or

to

change an attachment or accessory,

make sure the spark plug wire

is

disconnected from the spark plug.

Allow the engine to cool before

making any inspections, adjust-

ments, etc.

2. Maintain equipment and all at-

tachments and accessories in a

clean, and safe working condition.

SAFETY

DECALS

3. Never perform any maintenance

while the engine

is

running or when

the spark plug wire

is

connected to

the spark plug, except where specif-

ically instructed

to

do

so.

4.

Never store this equipment with

fuel

in

the fuel tank inside a build-

ing where fumes may reach an

open flame or spark, or where igni-

tion sources are present such as hot

water and space heaters, furnaces,

clothes dryers, stoves, electric mo-

tors, etc.

5. Allow engine to cool before

storing

in

any enclosure.

6. Store gasoline in a cool, well-

ventilated area, safely away from

any spark- or flame-producing

equipment. Store gasoline in an

approved container, safely out

of

the reach

of

children.

7. Use only original equipment re-

placement parts. Parts manufac-

tured

by

others could present a

safety hazard even though they

may fit on this equipment.

8. Store this equipment where

children will not have access to it.

Disconnect the spark plug wire

from the spark plug.

9. Check collection bag frequently

for deterioration or wear and re-

place worn bags. Use only origi-

nal-equipment replacement bags.

Bags manufactured by others could

present safety hazards.

10. Refer to the Engine Owner's

Manual and to

"Off

Season

Storage" in Section 5

of

this

Manual for important storage in-

structions

if

equipment

is

to be

stored for an extended period.

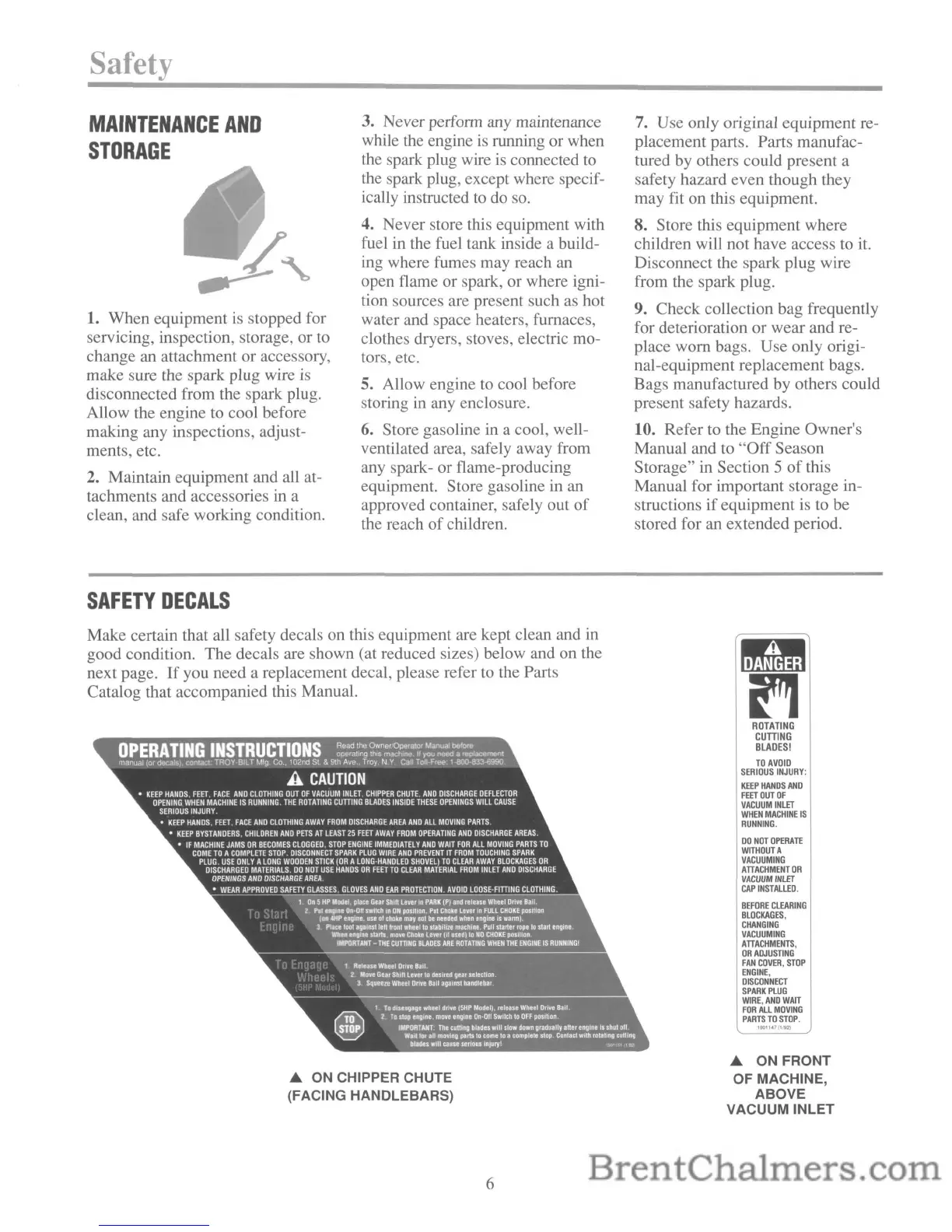

Make certain that all safety decals on this equipment are kept clean and in

good condition. The decals are shown (at reduced sizes) below and on the

next page.

If

you need a replacement decal, please refer to the Parts

Catalog that accompanied this Manual.

ROTATING

CUTTING

BLAOESI

TO

AVOID

SERIOUS

INJURY:

KEEP

HANDS

AND

FEET

OUT

OF

VACUUM

INLET

WHEN

MACHINE

IS

RUNNING.

DO

NOT

OPERATE

WITHOUT

A

VACUUMING

ATTACHMENT

OR

VACUUM

INLET

CAP

INSTALLED.

BEFORE

ClEARING

BLOCKAGES,

CHANGING

VACUUMING

ATTACHMENTS,

DR

ADJUSTING

FAN

COVER,

STOP

ENGINE,

DISCONNECT

SPARK

PLUG

WIRE,

AND

WAIT

FOR

ALL

MOVING

PARTS

TO

STOP.

1901'.7(1192)

....

ON CHIPPER CHUTE

(FACING HANDLEBARS)

6

....

ON FRONT

OF MACHINE,

ABOVE

VACUUM INLET

Loading...

Loading...