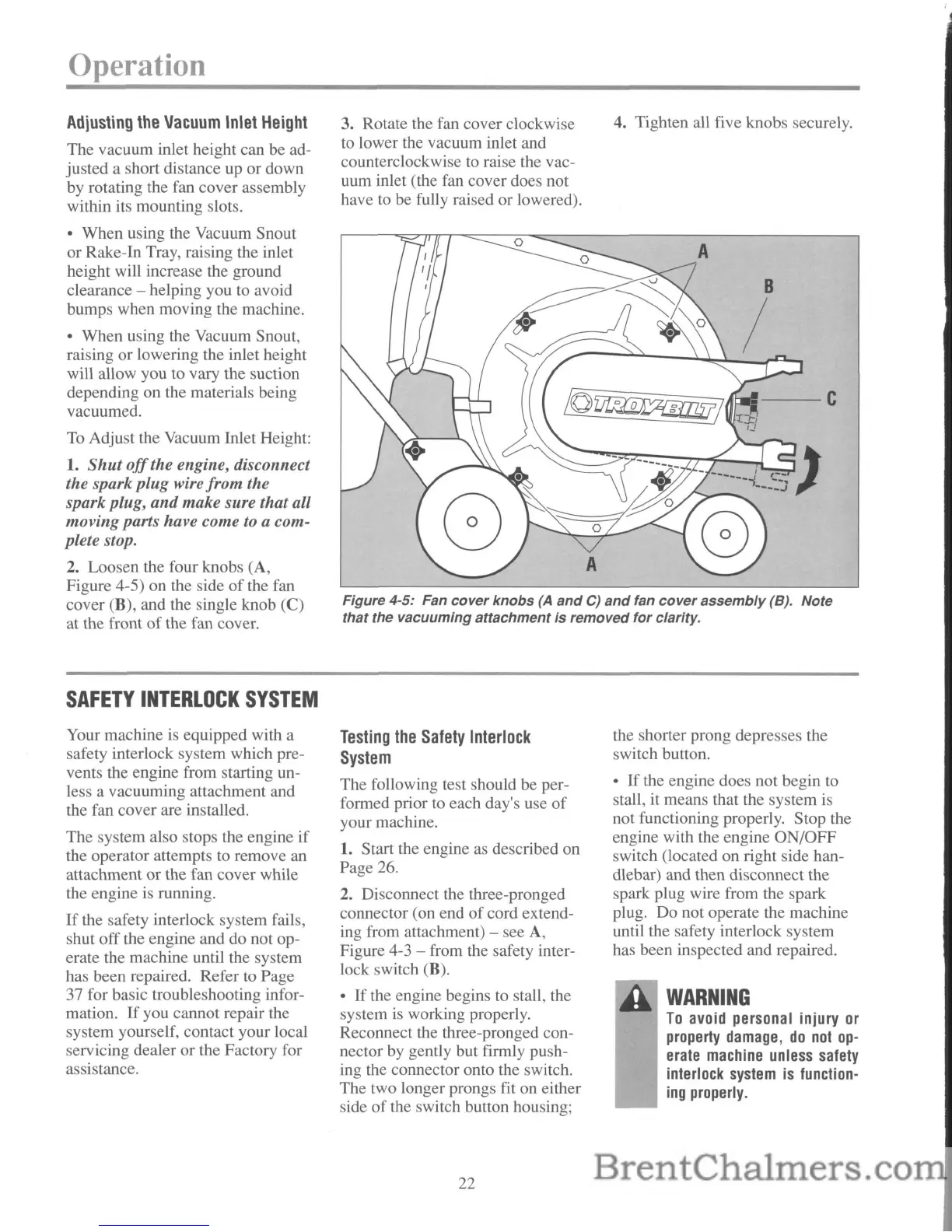

Figure 4-5: Fan

cover

knobs

(A

and

C)

and

fan

cover

assembly

(8).

Note

that

the vacuuming attachment

is

removed

for

clarity.

Operation

Adjusting

the

Vacuum

Inlet

Height

The vacuum inlet height can be ad-

justed a short distance

up

or down

by rotating the fan cover assembly

within its mounting slots.

• When using the Vacuum Snout

or Rake-In Tray, raising the inlet

height will increase the ground

clearance - helping you to avoid

bumps when moving the machine.

• When using the Vacuum Snout,

raising or lowering the inlet height

will allow you to vary the suction

depending on the materials being

vacuumed.

To

Adjust the Vacuum Inlet Height:

1.

Shut

off

the engine, disconnect

the spark plug wire from the

spark plug,

and

make sure that all

moving parts have come

to

a com-

plete stop.

2. Loosen the four knobs (A,

Figure 4-5) on the side

of

the fan

cover (B), and the single knob

(C)

at the front

of

the fan cover.

SAFETY

INTERLOCK

SYSTEM

Your machine is equipped with a

safety interlock system which pre-

vents the engine from starting un-

less a vacuuming attachment and

the fan cover are installed.

The system also stops the engine if

the operator attempts to remove an

attachment or the fan cover while

the engine

is

running.

If

the safety interlock system fails,

shut offthe engine and do not op-

erate the machine until the system

has been repaired. Refer to Page

37 for basic troubleshooting infor-

mation.

If

you cannot repair the

system yourself, contact your local

servicing dealer or the Factory for

assistance.

3. Rotate the fan cover clockwise

to lower the vacuum inlet and

counterclockwise to raise the vac-

uum inlet (the fan cover does not

have to be fully raised or lowered).

Testing

the

Safety

Interlock

System

The following test should be per-

formed prior to each day's use

of

your machine.

1. Start the engine as described on

Page 26.

2. Disconnect the three-pronged

connector (on end

of

cord extend-

ing from attachment) - see

A,

Figure 4-3 - from the safety inter-

lock switch (B).

•

If

the engine begins to stall, the

system

is

working properly.

Reconnect the three-pronged con-

nector by gently but firmly push-

ing the connector onto the switch.

The two longer prongs fit on either

side

of

the switch button housing;

22

4. Tighten all five knobs securely.

.t~r;;---C

the shorter prong depresses the

switch button.

•

If

the engine does not begin to

stall, it means that the system is

not functioning properly. Stop the

engine with the engine ON/OFF

switch (located on right side han-

dlebar) and then disconnect the

spark plug wire from the spark

plug. Do not operate the machine

until the safety interlock system

has been inspected and repaired.

WARNING

To

avoid personal injury

or

property

damage,

do

not

op-

erate

machine

unless

safety

interlock

system

is

function-

ing

properly.

Loading...

Loading...