Features and Controls

I

Wire

Hoop

Debris

Guard

/

---0

---

Recoil

Starter

5HP

MODEL

Spark

Plug

/

Oil

Fill/Dipstick

\-r

Oil

Drain

?

Choke

/'

Air

Cleaner

Debris

Guard

/

----0

---

I

Wire

Hoop

4HP

MODEL

Recoil

Starter

\

Oil

Drain

Spark

Plug

\

Muffler

Chok'\

\

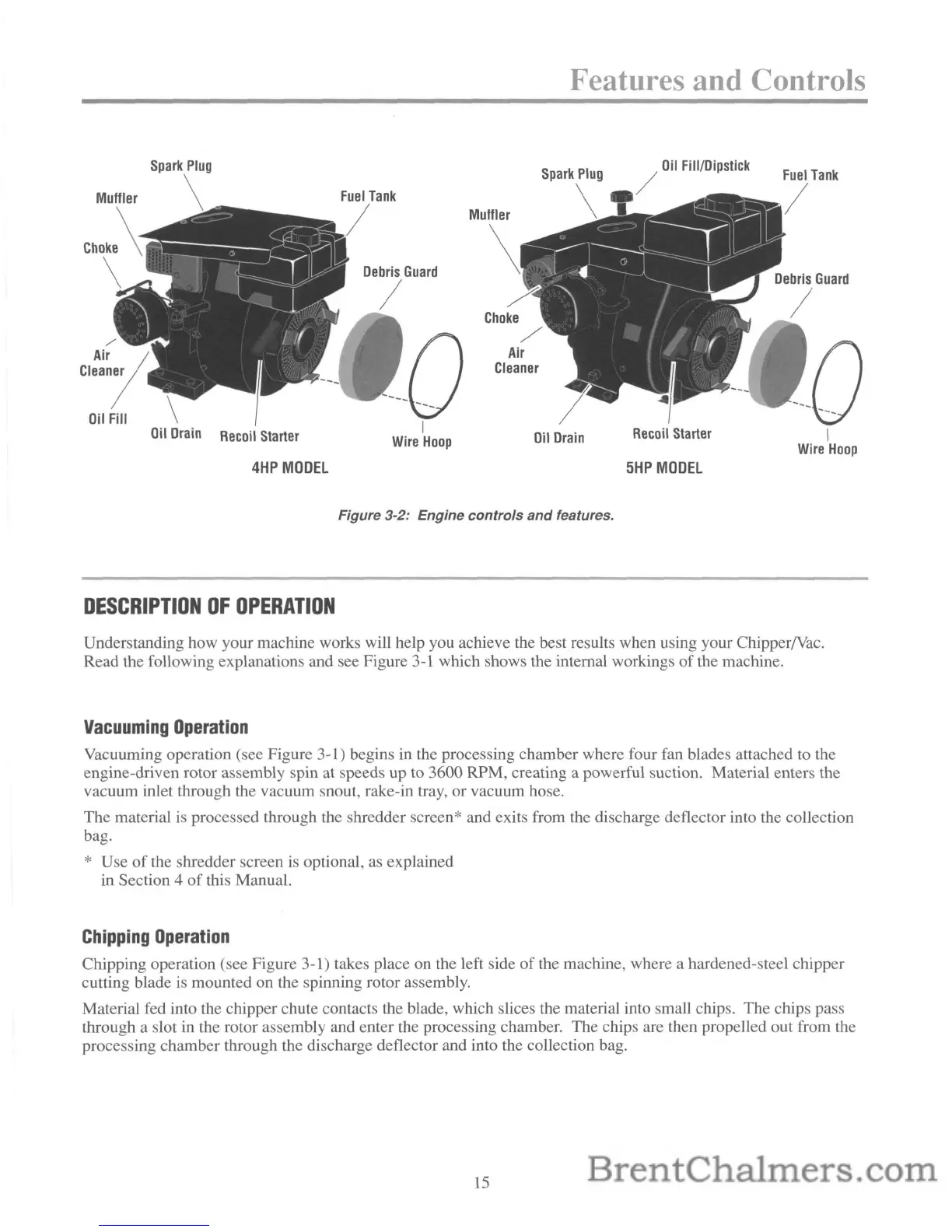

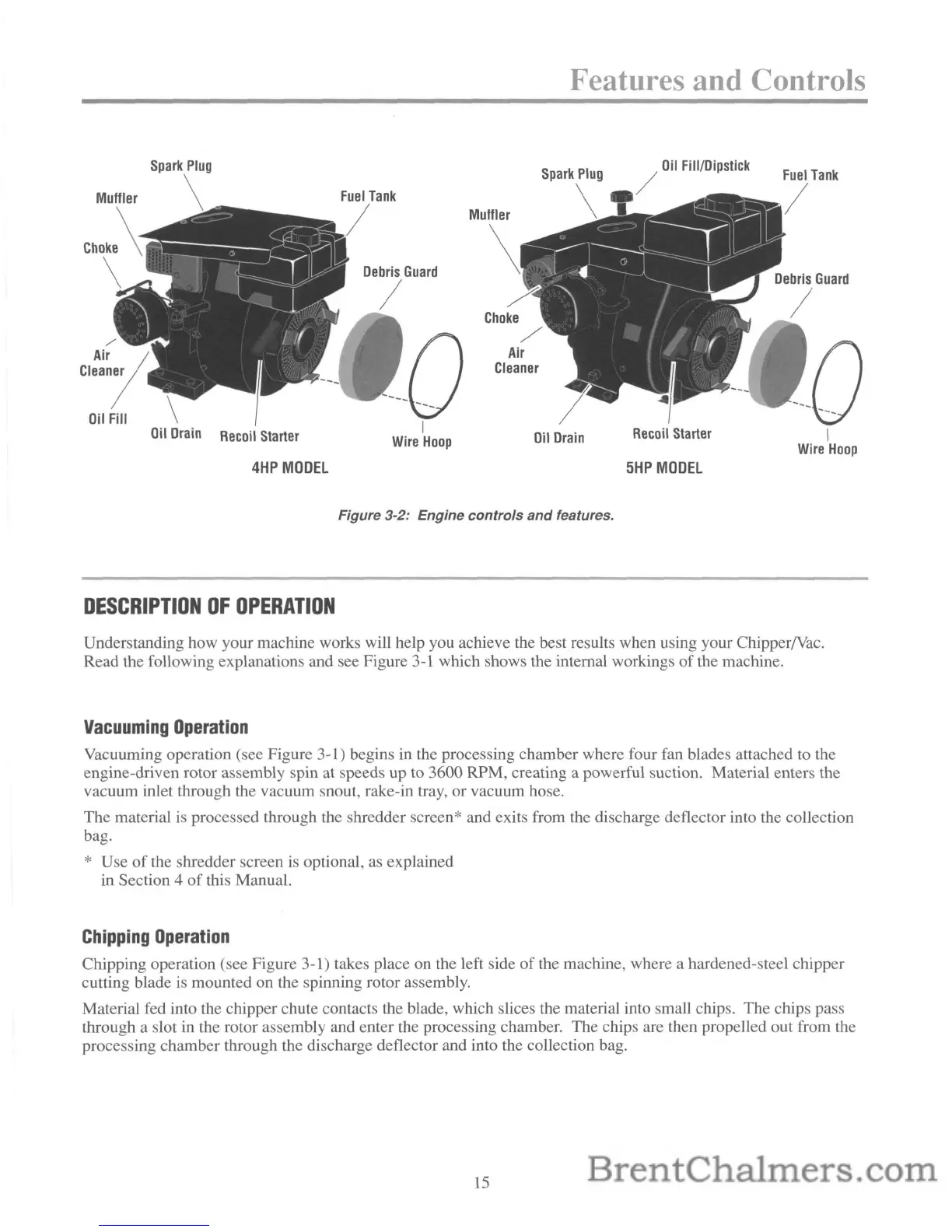

Figure 3-2: Engine

controls

and

features.

DESCRIPTION

OF

OPERATION

Understanding how your machine works will help you achieve the best results when using your ChipperNac.

Read the following explanations and see Figure 3-1 which shows the internal workings

of

the machine.

Vacuuming

Operation

Vacuuming operation (see Figure 3-1) begins in the processing chamber where four fan blades attached to the

engine-driven rotor assembly spin at speeds up to 3600 RPM, creating a powerful suction. Material enters the

vacuum inlet through the vacuum snout, rake-in tray, or vacuum hose.

The material is processed through the shredder screen* and exits from the discharge deflector into the collection

bag.

* Use

of

the shredder screen is optional, as explained

in Section 4

of

this Manual.

Chipping

Operation

Chipping operation (see Figure 3-1) takes place on the left side

of

the machine, where a hardened-steel chipper

cutting blade is mounted on the spinning rotor assembly.

Material fed into the chipper chute contacts the blade, which slices the material into small chips. The

chips pass

through a slot in the rotor assembly and enter the processing chamber. The chips are then propelled out from the

processing chamber through the discharge deflector and into the collection bag.

15

Loading...

Loading...