The condition of ISO 4259 within

the range should be applied in be-

tween the maximum and minimum

values. Also, the minimum differ-

ence of 4 x R (R = reproducibili-

ty of test method) should be con-

sidered. However, in order to keep

the quality high, 4 x R is not con-

sidered for the urea concentration.

Values for the urea concentration,

density and refractive index are

actual values. (Refer to ISO 4259

for actual values.)

The AUS 32 manufacturer pro-

duces products based on the val-

ues for the annotation a, d and e.

It is necessary to check if urea is

satised with the required speci-

cations. The ISO 4259 conditions

should be applied.

•

•

•

•

NOTE

It is necessary to add a tracer ele-

ment to AUS 32. Make sure that the

SCR system is not damaged by the

quality of AUS 32 specied in the ta-

ble and tracer element.

8 CHECKING AND CLEANING AIR CLEANER

Check and clean the air cleaner pe-

riodically as follows:

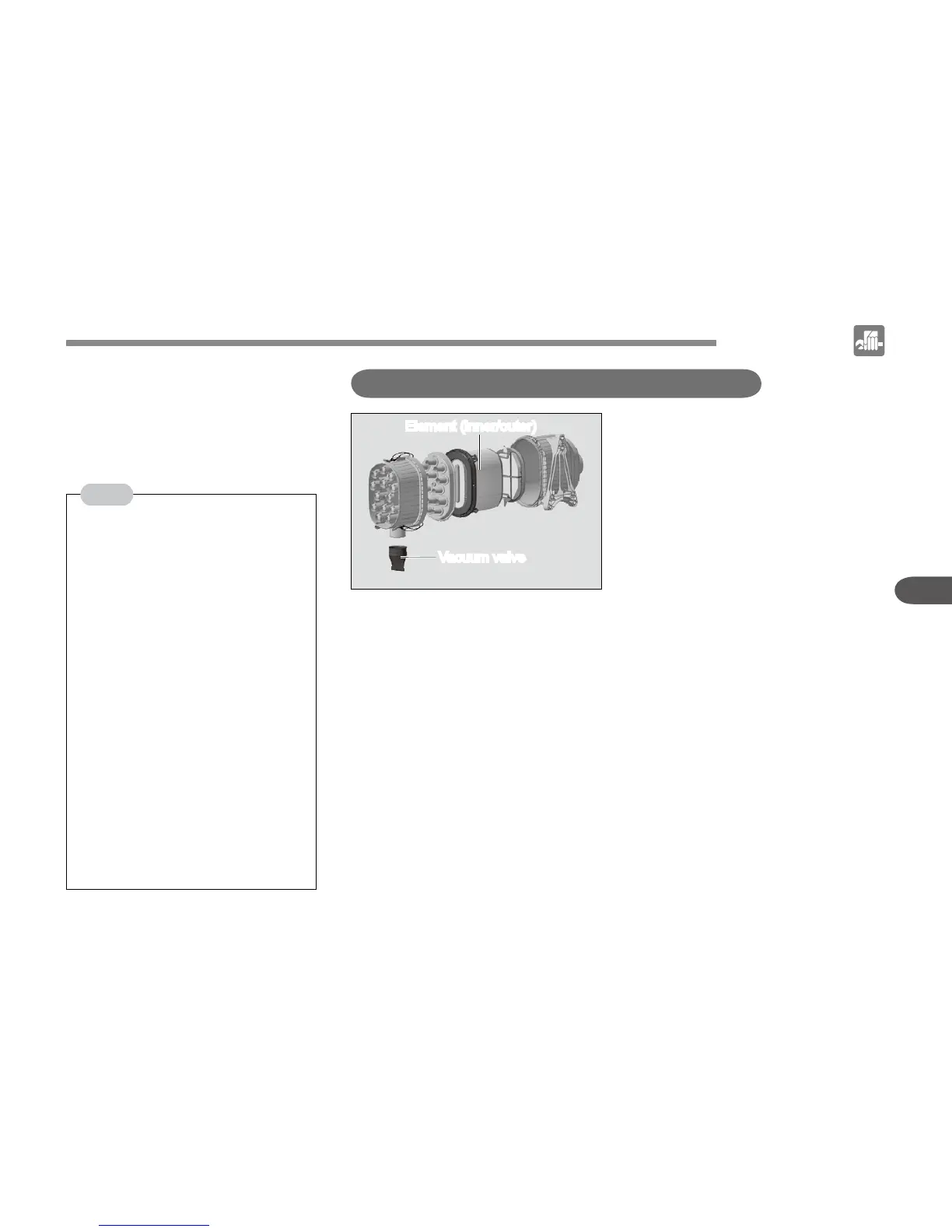

CLEANING VACUUM VALVE

Pull out the valve with a hand and

remove dust from its inside. If it is

dirty or watery, wipe it with a dry rag

thoroughly before tting it again.

< Precautions for inspection and

service of air cleaner >

(1) Use only standard elements and

do not apply oil on it.

(2) Foreign materials in the cover

should be removed thoroughly

as well.

►

(3) Make sure to install it securely

so that foreign materials do not

enter the cover.

(4) Never drive the vehicle with the

element removed.

CLEANING ELEMENT

Blow compressed air from the inside

toward the outside of the element.

Keep proper distance between the

air nozzle and element.

REPLACING ELEMENT

After cleaning the element 5 times

or if it is damaged, replace it with a

new one.

CLEANING COVER

Undo the clip and remove the cover

to wash it thoroughly with water.

►

►

►

Vacuum valve

Element (inner/outer)

J10O533A

Loading...

Loading...