110

Cooling system

6

Check the components for signs of damage and re-

place if necessary.

7

Slide the sleeve (A1) on the end of the insert until

the insert is in contact with the reduced diameter of

the sleeve.

8

Press a rubber end (A2) over the other end of the

insert until the protrusion inside the rubber end

touches the end of the sleeve.

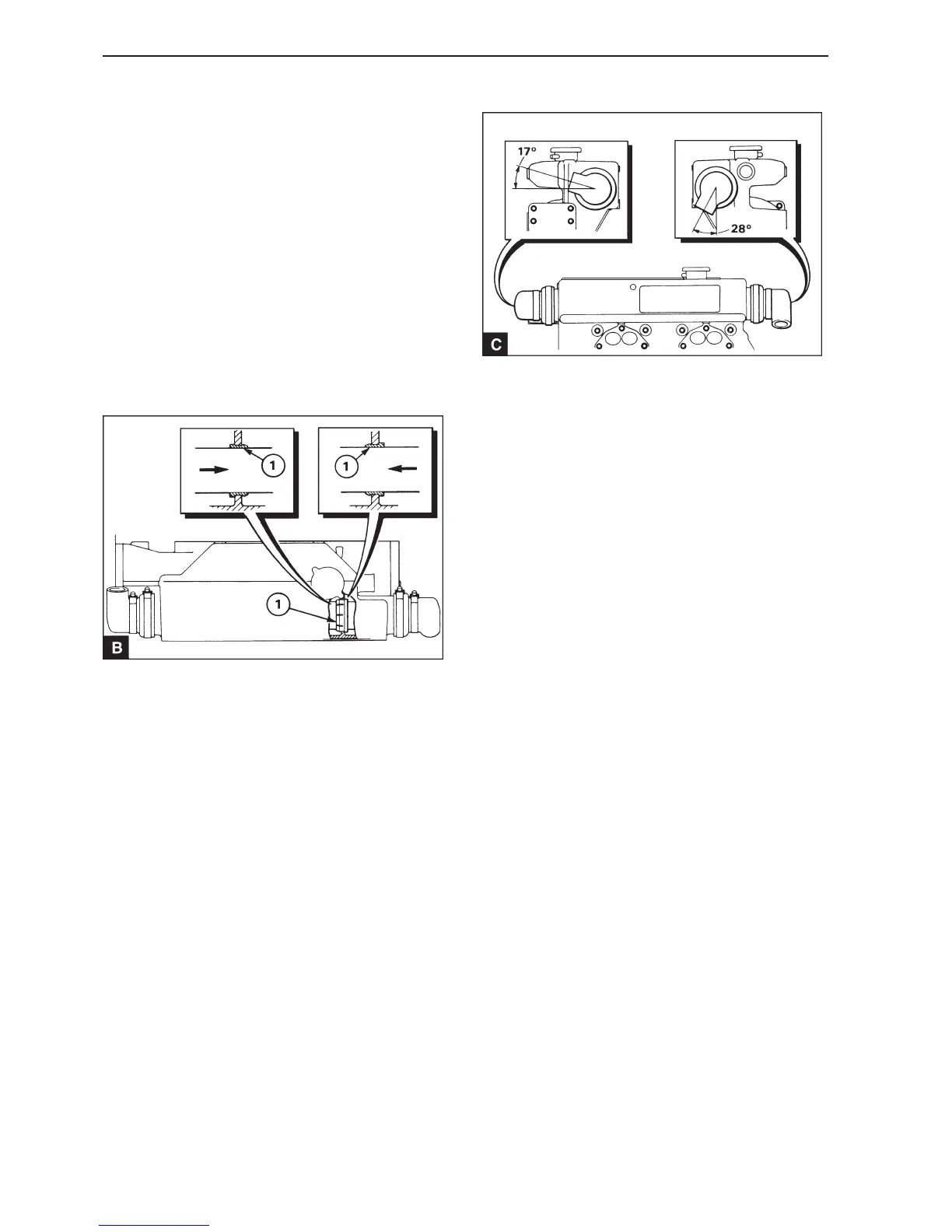

9

Install the second rubber end. Check that the pipe

connectors of the rubber ends are in the correct po-

sition and tighten the clamps. Place the rubber ends

in the positions shown in C if the assembly has be

removed from the engine.

11

Connect the sea water intake and outlet pipes to the

heat exchanger. The output pipe must be pushed in

so that the end of the pipe is in the center of rubber

end of the heat exchanger. Tighten the clamp to the

outlet pipe.

12

Fill the coolant circuit, operation 20A-02 and open

the seacock.

13

Run the engine and check for leakage.

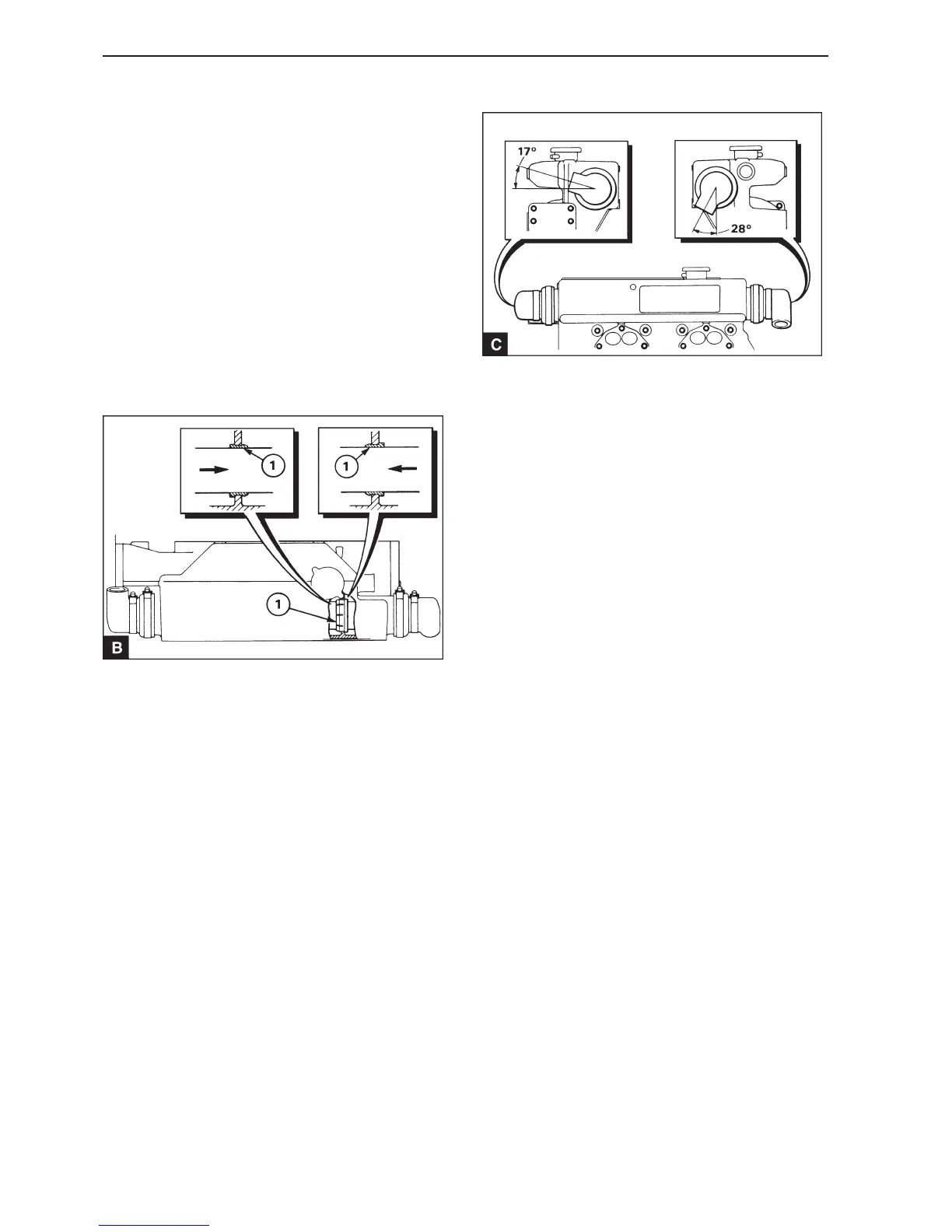

If a rubber sleeve is used, lubricate it with a little

soap solution. Place the sleeve end of the assembly

in the housing and carefully insert the sleeve in the

hole in the baffle plate Carefully press the pipe ends

of the housing until the journal in the housing is cor-

rectly positioned inside the end cover. Do not pull

the pipe cluster backwards during installation, as

this pulls the sleeve out of the baffle plate. Check

through the filler opening that the sleeve is posi-

tioned correctly in the baffle plate (B).

10

Loading...

Loading...