30

Cylinder head

Valve guides, inspection

(12A-10)

Special tools: 885021, 885022

Check the valve guides for wear. The maximum

play between the valve stem and the hole in the

guide is 0.13 mm. If the clearance is greater when a

new valve is installed, a new valve guide must be

installed.

6

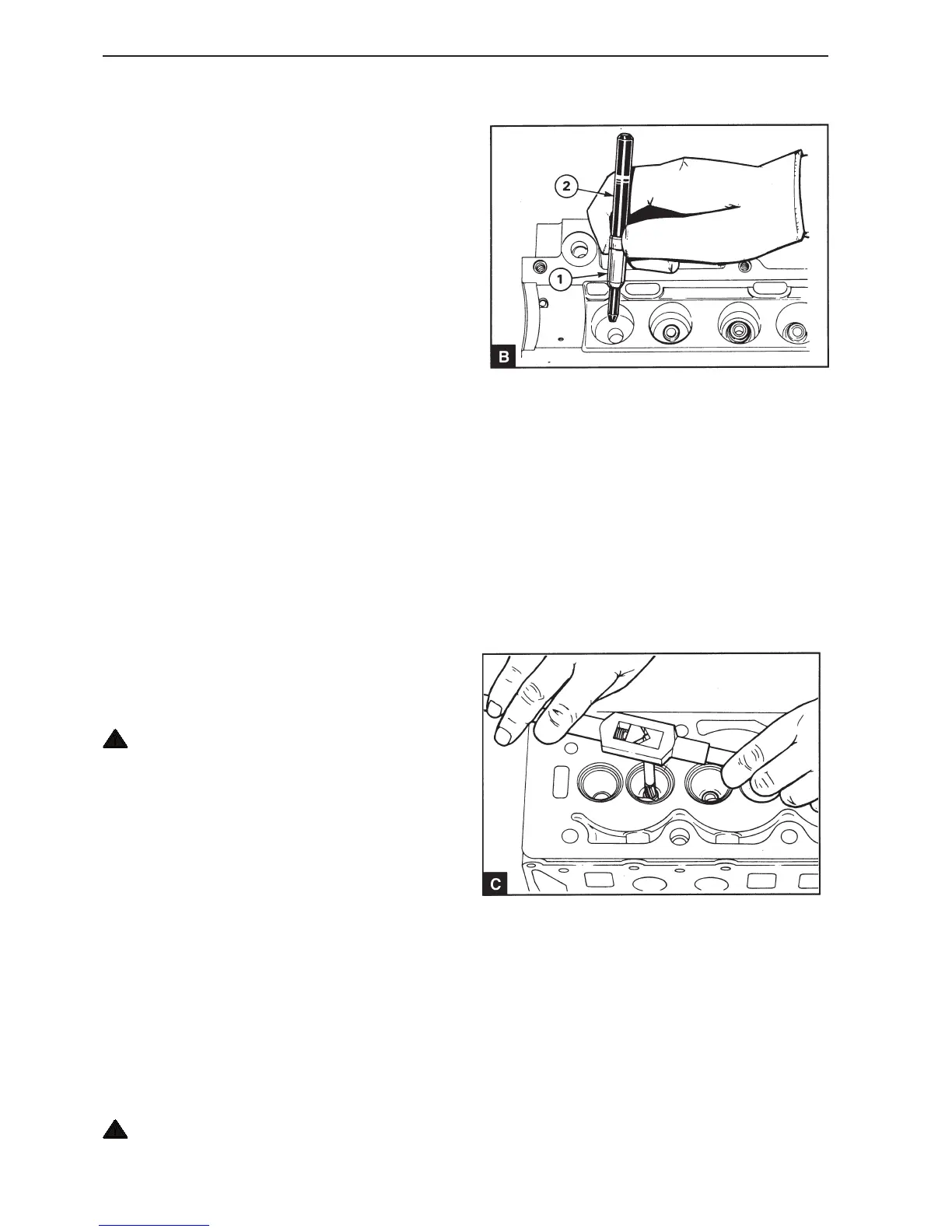

Install the guide B1 on the thin end of the tool

885021 (B2) with the bevel turned to the thin end of

the tool (B). Insert the bevelled end of the guide into

position in the cylinder head and press in the guide

until the tool end comes into contact with the flat

plate. Check that the guide protrudes 10 mm above

the mating surface for the valve spring.

7

Allow the cylinder head to cool.

8

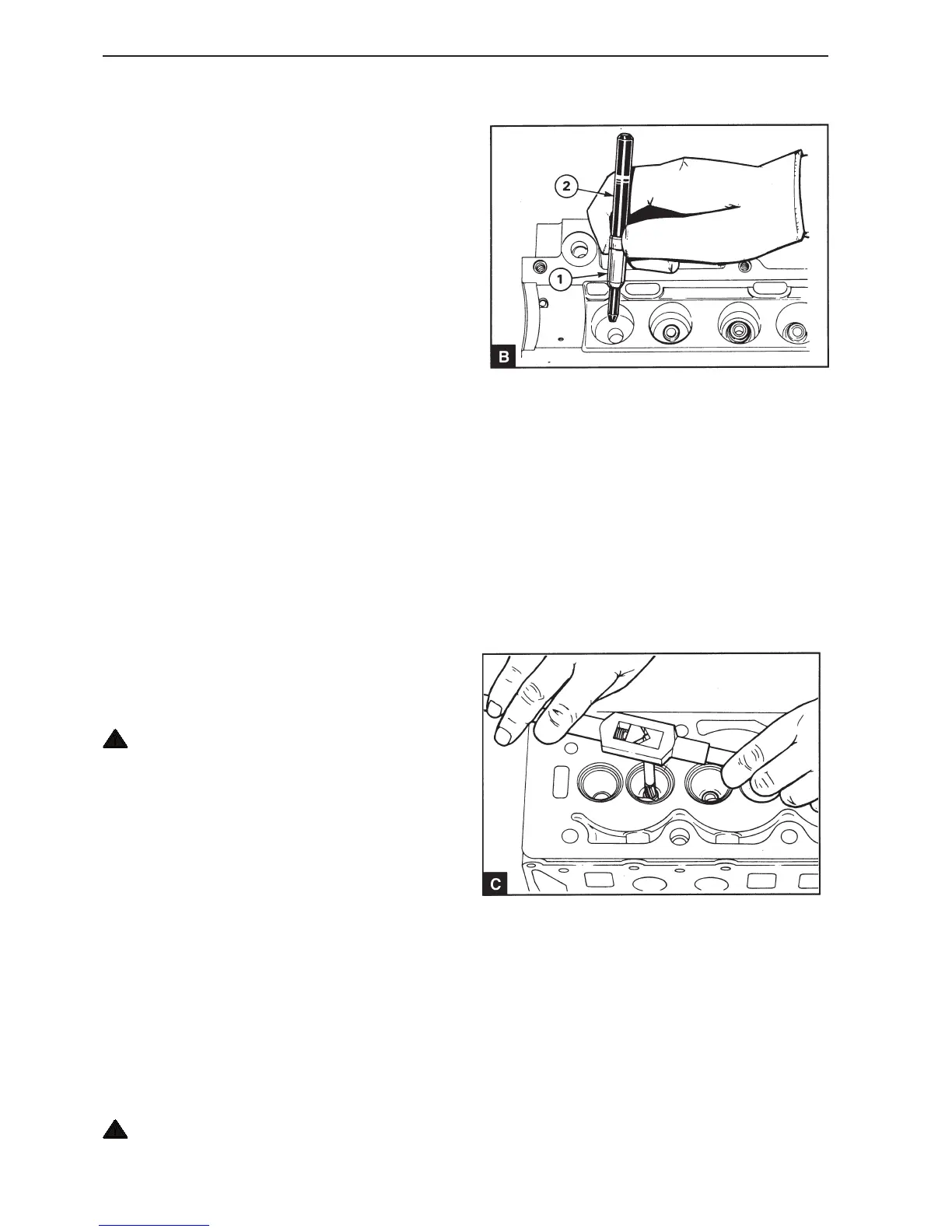

Ream the hole for the new guide using reamer

885022 (C).

Valve guides, replacement

(12A-11)

1

Ensure that the surface of the cylinder head and the

storage surface in a suitable press are clean.

2

Heat the whole cylinder head slowly and evenly to

approximately 100°C and lay the head with the sur-

face downwards. Ensure that the surface is not

damaged during handling.

WARNING! Use suitable gloves as protection

against the hot metal.

3

Install the thin end of tool 885021 in the guide and

press it out. Repeat the procedure if several guides

need to be replaced.

4

Clean the valve guide position and ensure that it is

not damaged.

5

Heat the whole cylinder head slowly and evenly to

approximately 100°C. Lay the head in the press with

the surface downward with a flat surface located un-

der the valve opening. Ensure that the head surface

is not damaged during handling.

WARNING! Use suitable gloves as protection

against the hot metal.

Loading...

Loading...