41

Piston and connecting rod

8

Place the connecting rod with piston upside down.

The locating lug (B2) on the connecting rod must be

on the same side as the arrow (B1) on the under-

side of the piston.

9

Lubricate the piston bolt position in the piston with

fresh engine oil and slide in the piston bolt towards

the snap ring. If the piston bolt has difficult to insert,

heat the piston to 40°-50°C before the piston bolt is

installed.

10

Install a new snap ring in the other piston bolt posi-

tion on the piston. Ensure that it goes into the

groove correctly.

11

Install the piston rings, operation 13A-04.

Piston and piston rings,

inspection (13A-06)

1

Check the piston for wear and damage.

2

Check that the piston rings can move freely in its

groove and that no ring is broken.

3

Remove the piston rings, operation 13A-04. Clean

the piston ring and the piston ring grooves.

4

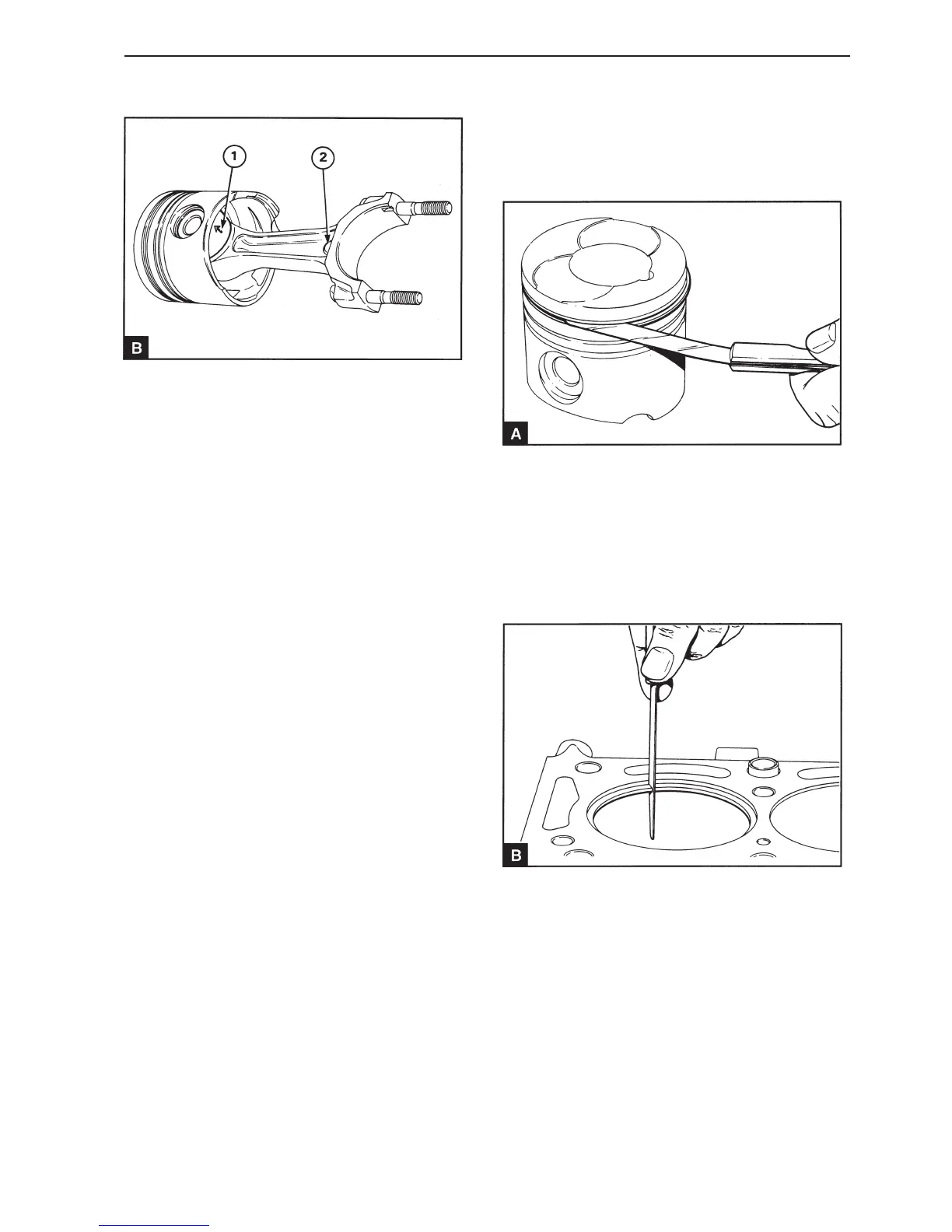

Install the new piston rings in the piston ring groove

and check the ring groove wear using the feeler

gauge (A). Compare the piston ring play in the

groove to the values that apply to new components

in the Workshop Manual “Technical Data”. Replace

the cylinder if necessary.

5

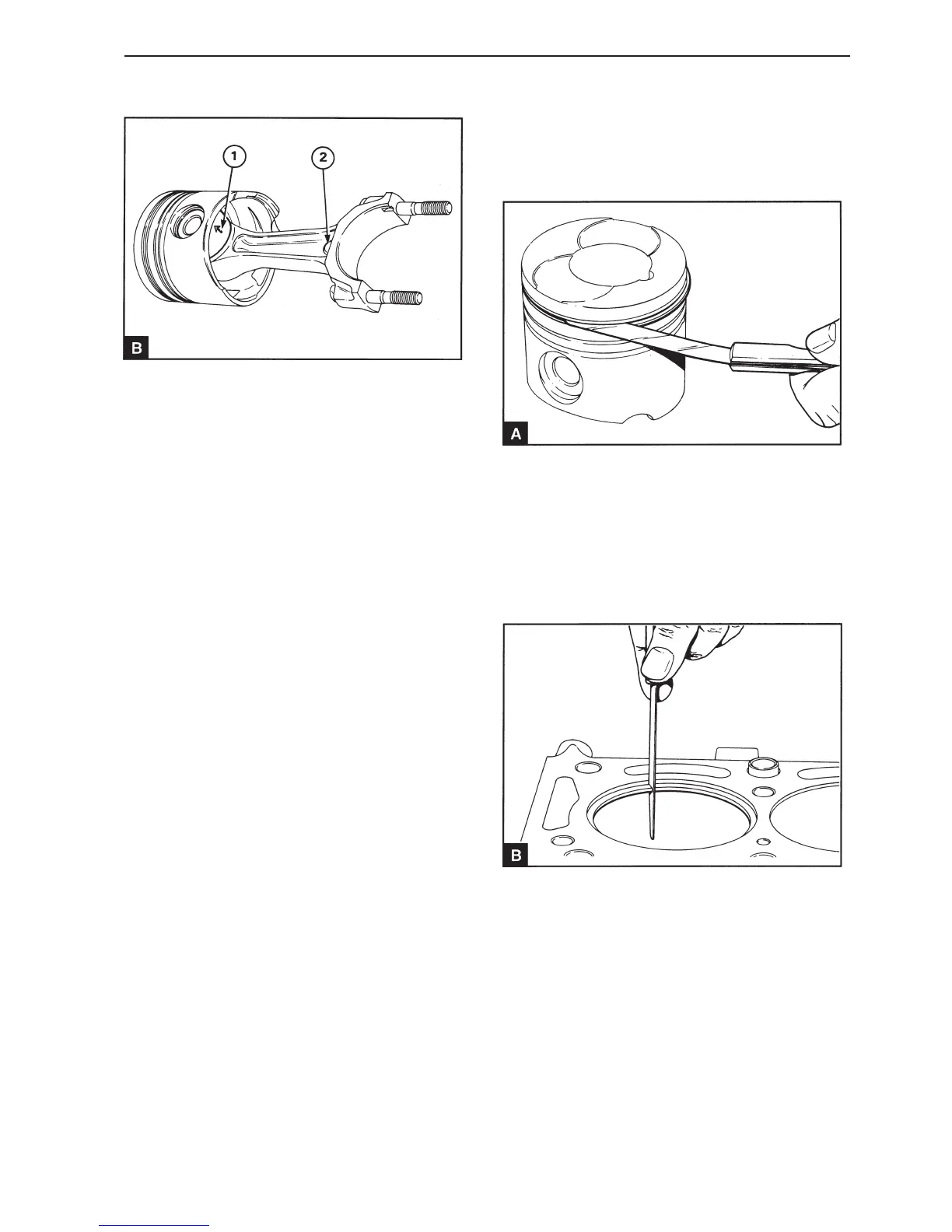

Check that all the soot has been removed from the

upper section of the cylinder bore. Install the piston

rings in the upper section of the cylinder bore and

measure the ring gap with a feeler gauge (B). The

expander ring must be installed on the oil scraper

ring when the ring gap is measured. The ring gap for

the new components is given in the Workshop man-

ual “Technical data”.

Loading...

Loading...