85

Fuel injection system

Injectors, fault-tracing

A faulty injector can cause engine misfires.

To find the faulty injector, run the engine at high

idling speed. Slacken off and tighten the connector

nut for the delivery line for each injector. When the

connector nut for the faulty injector is slackened off

it has little or no effect on the engine speed (RPM).

WARNING! Ensure that fuel is not sprayed

onto your skin.

Injectors, replacement

(19A-02)

1

Remove the leak fuel line.

2

Remove the connector nuts for the delivery lines

from the injectors and from the fuel injection pump.

Hold the pump outlet with a wrench to prevent the

join from moving when the terminal is slackened off.

Do not bend the pipe. Replace the pipe clamps if re-

quired.

3

4

Check the holder unit for wear and deformation and

replace the unit if required. Replace the injector

seat gasket.

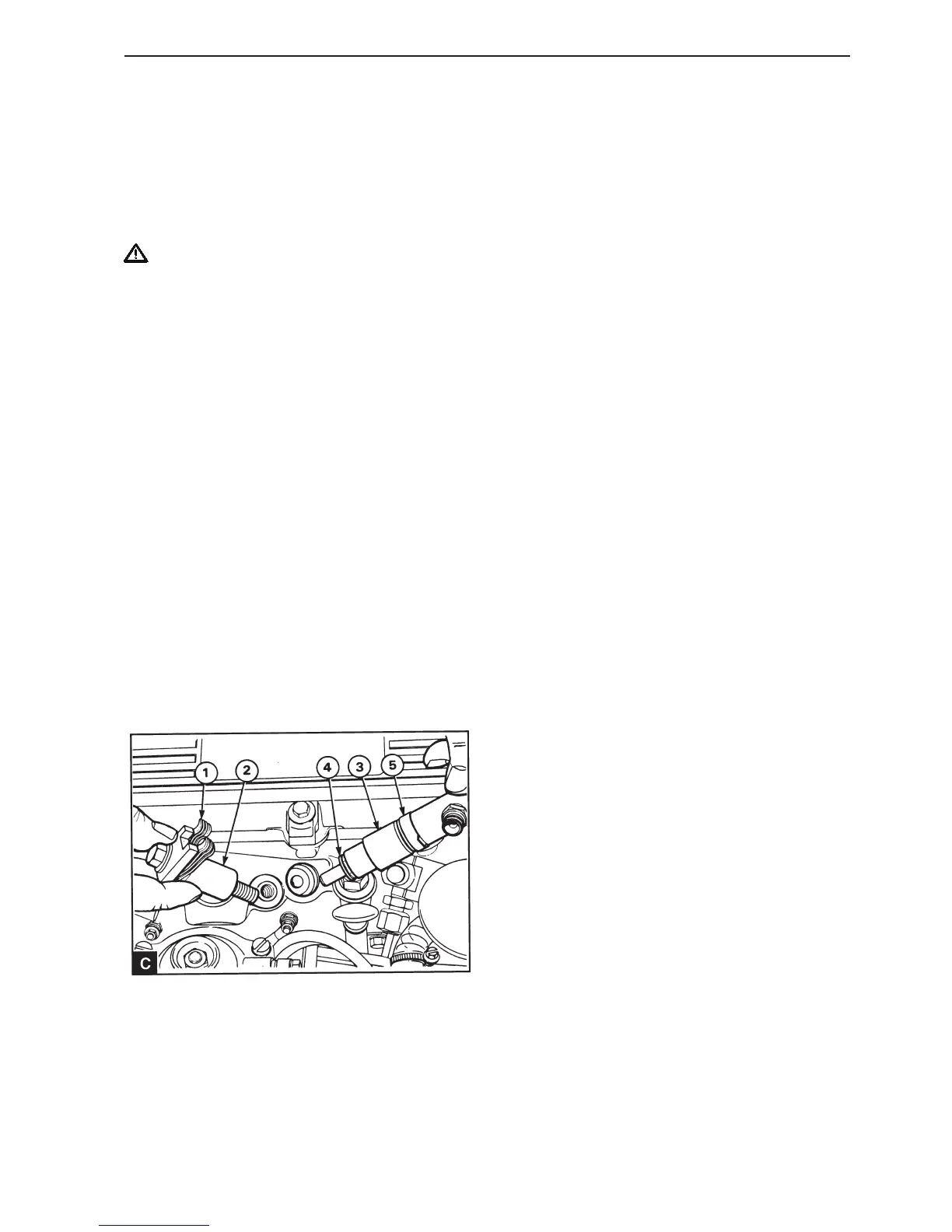

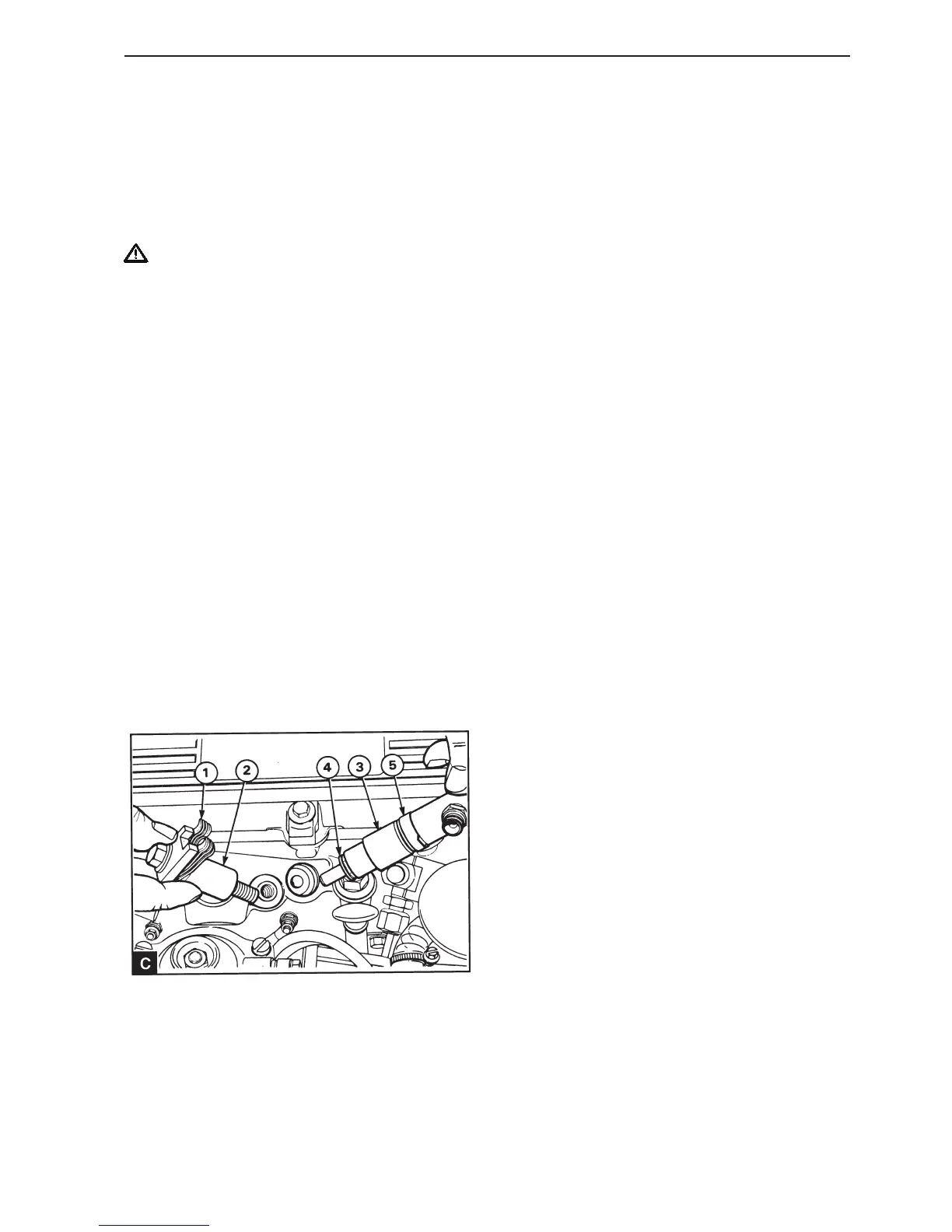

5

Check that the injector guide ring (C5) is in position

in the cylinder head and install the new injector and

seat gasket. Check that the injector is not crooked.

Install the holder unit and the spacer with holder

arms placed at right angles on the injector’s projec-

tion. Tighten the holder mounting screws to 43 Nm.

6

Install the delivery lines and tighten the connector

nuts to 18 Nm. Hold the pump outlet with a wrench

to prevent the join from moving when the nut is

tightened. Install the pipe clamps if required.

7

Install the leak fuel line.

8

Start the engine and check that there are no air and

fuel leaks.

Slacken off the mounting screws for the injector

holders. The spacer piece (C2) should either be

31.5mm or 7 mm long, depending on which type of

injector is used. If a short spacer is used, lift the

spring unit when the mounting screw is removed.

This ensures that the mounting screw threads do

not go in the hole in the lower spring. Remove the

holder (C1) and the spacer washer. Remove the in-

jector (C3) and the seat gasket (A4).

Loading...

Loading...