32

Cylinder head

Valve seat, grinding (12A-13)

1

If the valve guide is worn it should be replaced, op-

eration 12A-11.

2

Install the locating pin in the valve guide and tighten

it.

3

14

Valve seats with more serious damage can be cor-

rected using a milling tool, operation 12A-13 or a

new valve seats can be installed, operation 12A-14.

15

Install the valve springs and valves, operation 12A-

08.

16

Install the camshaft cover, operation 12A-01 and

the camshaft. Install the valve lifters and shims in

their correct positions. Install the camshaft in posi-

tion and check the valve clearance, operation 12A-

02 and adjust as necessary, operation 12A-03.

17

Install the seawater pump, operation 20A-06.

18

Install the thermostat housing.

19

Install the cylinder head assembly, operation 12A-

07.

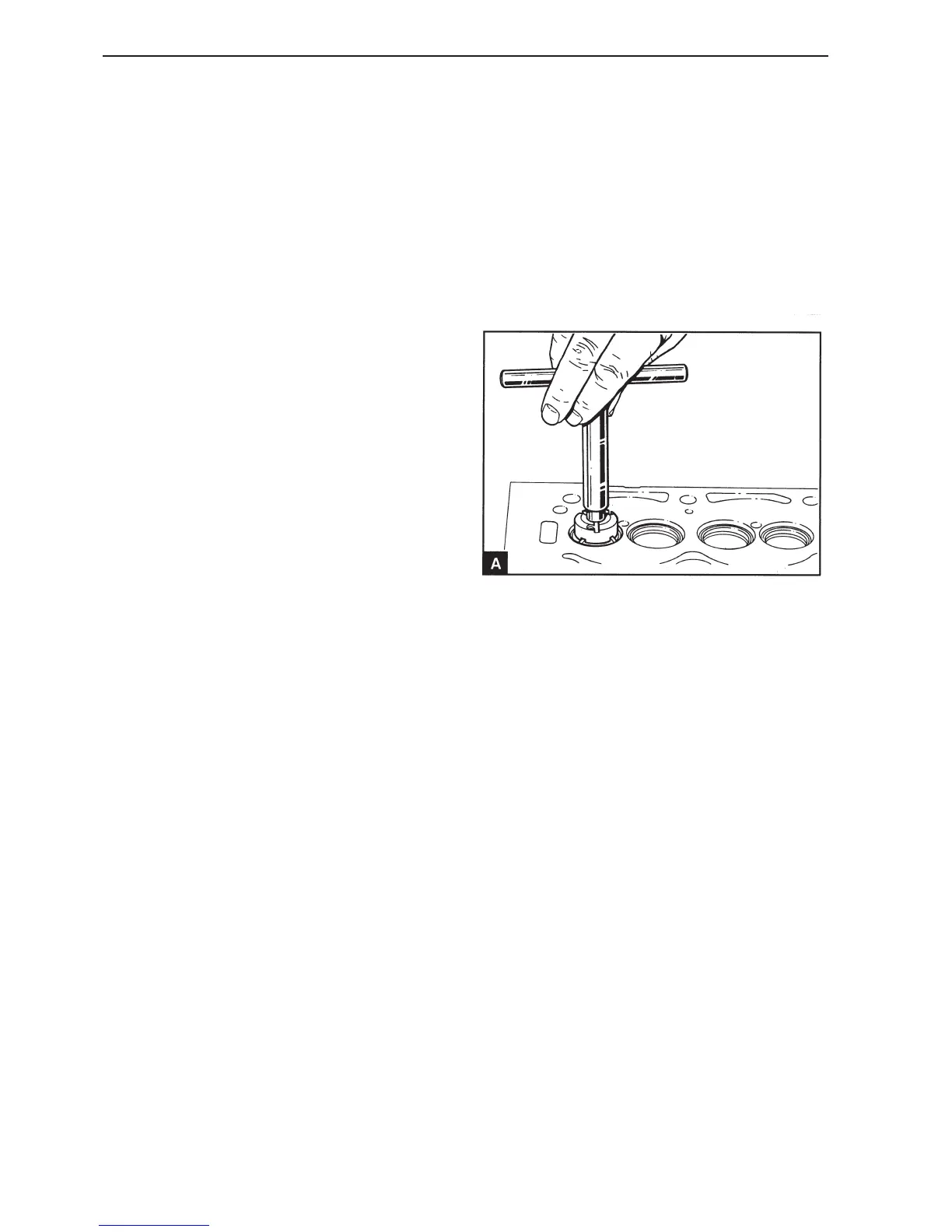

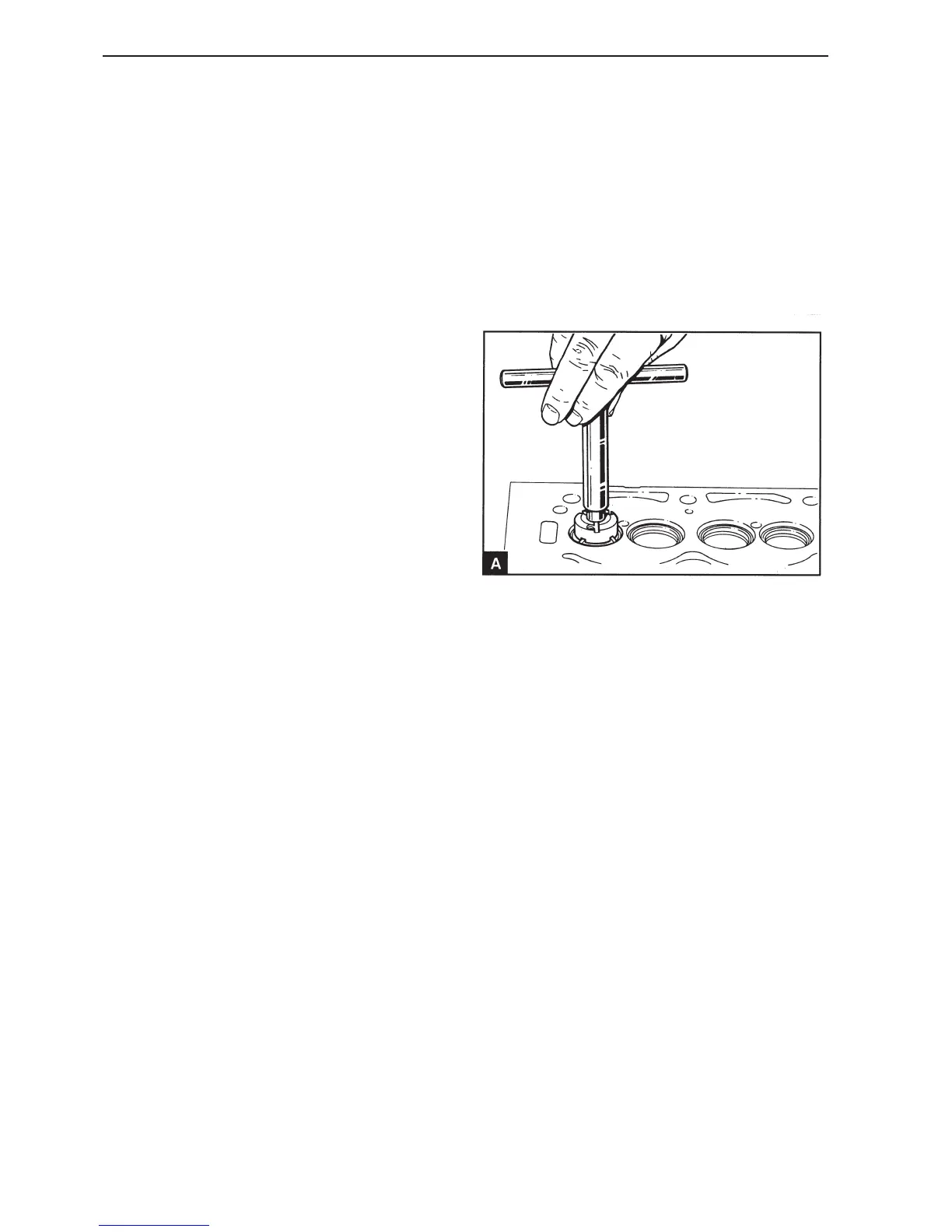

Install the mill on the locating pin with 46° side

against the valve seat and install the handle (A). Do

not let the mill head fall down towards the seat, this

can damage the blade.

4

Turn the mill carefully clockwise. Only remove as

much material as is necessary to achieve a seal.

Keep the sealing area as thin as possible.

5

Remove the mill and the locating pin when a satis-

factory sealing area has been achieved. Remove all

the work remnants from the area around the valve

seat and valve opening.

6

Install the valve and lightly lap the valve and seat.

7

Check that valve depth lies within the permitted pa-

rameters, see Workshop Manual “Technical Data”.

If a valve seat has become too damaged or worn it

must be replaced, operation 12A-14.

Loading...

Loading...