113

Flywheel, flywheel cover

8

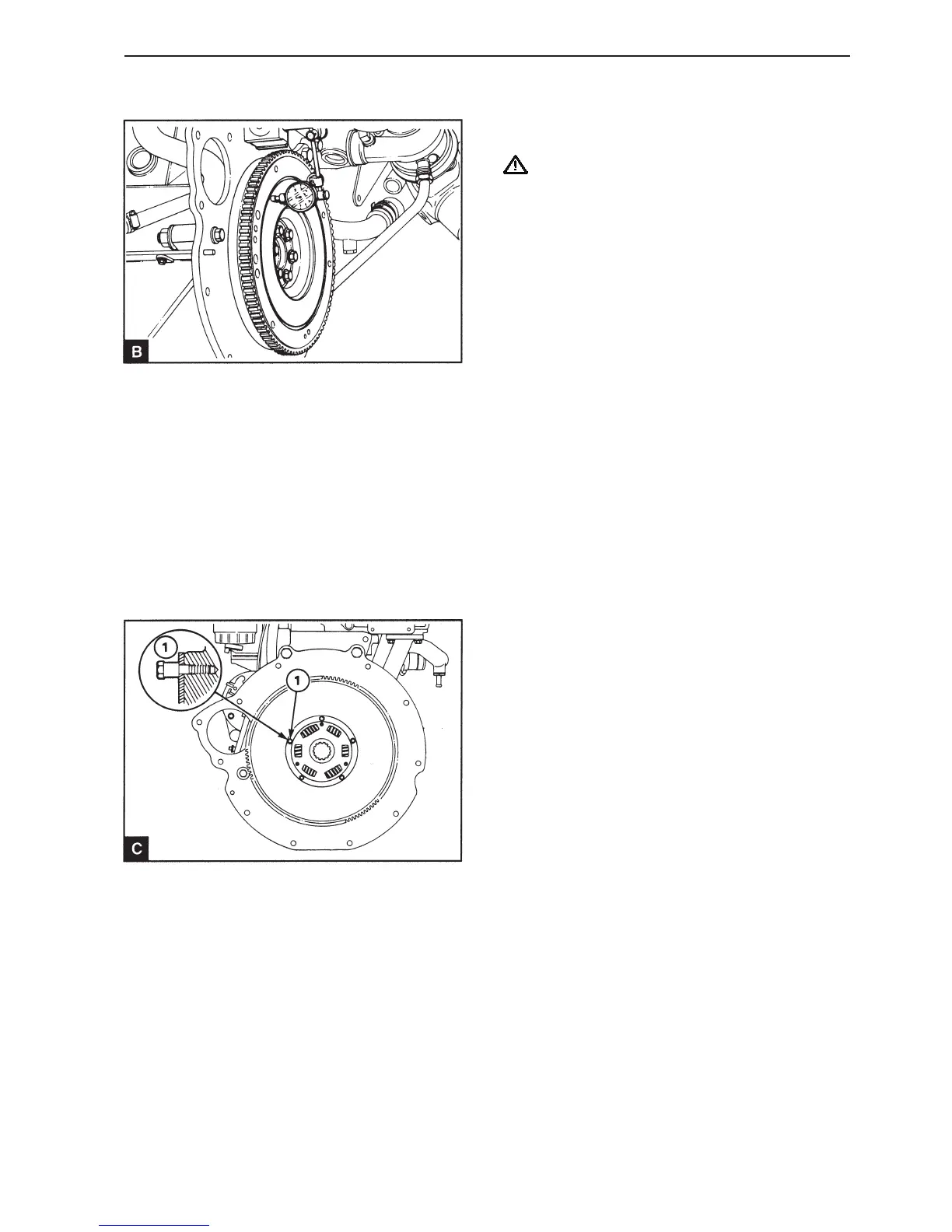

Check the axial run-out on the flywheel surface (B).

The axial run-out must not be greater than 0.03 mm

as a total reading on the dial indicator for every 25

mm radius of the flywheel (calculated from the cent-

er of the crankshaft to the tip of the dial indicator).

During this measurement, the crankshaft must be

pressed forward to prevent the axial run-out of the

crankshaft from affecting the reading.

MS2, 120S, HBW250, HS25

9

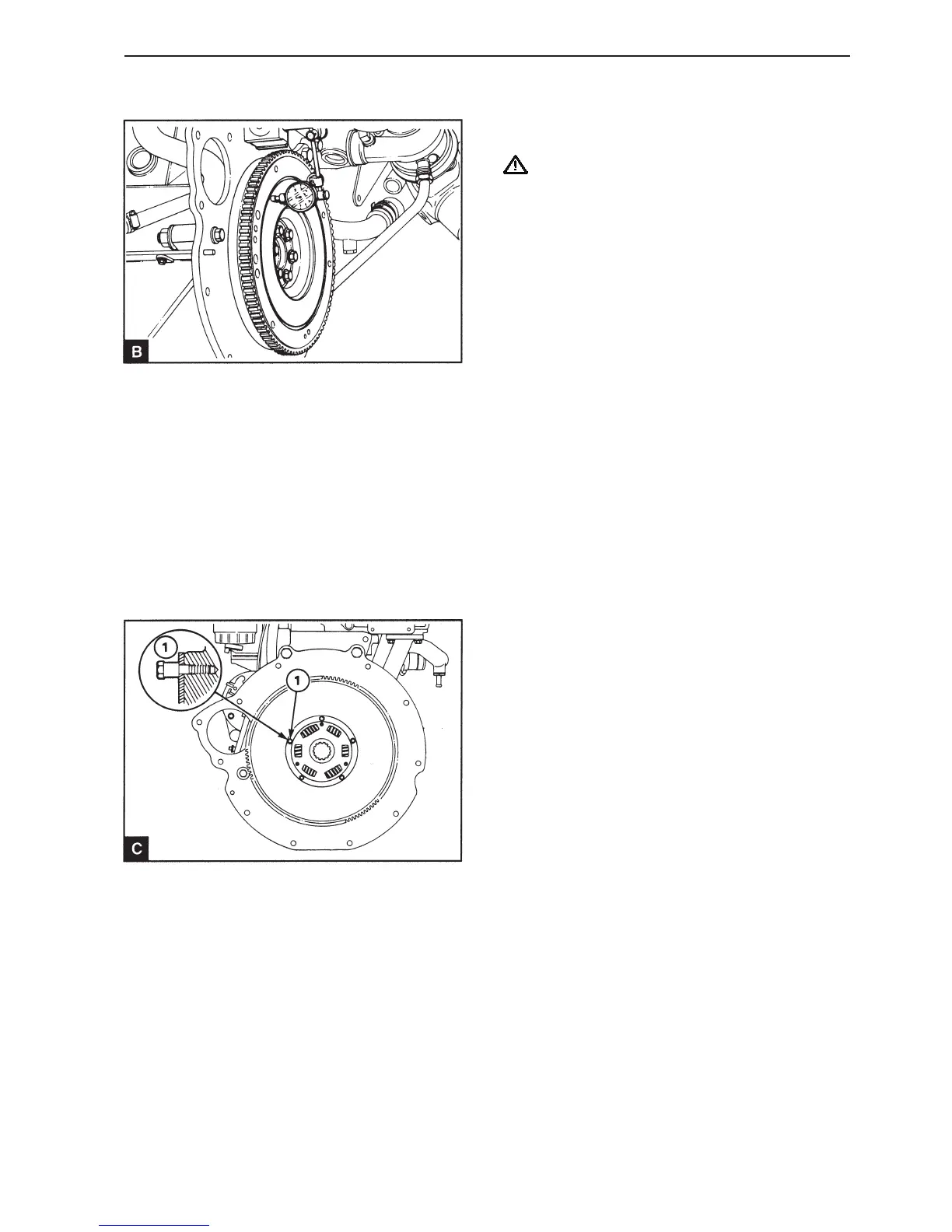

Install the elastic disc for the reverse gear (C). Ap-

ply Locktite 243 on the threads of the mounting

screws for the disc. Ensure that the small guide

section of each mounting screw goes into the fly-

wheel (C1). Tighten the mounting screws evenly in

stages to 9 Nm. Do not start the engine until the

locking fluid has hardened.

10

Install the drive components at the rear of the en-

gine.

Ring gear, replacement

(21A-01)

WARNING! Protective goggles must be worn

for this operation.

Check the position of the chamfering on the teeth

before removing the ring gear.

Removing

The ring gear can be removed using a hammer and

chisel to break off the collar. Make sure that the fly-

wheel is not damaged during this operation.

Installation

The collar is installed on the flywheel by heating it.

When a new collar is installed, ensure that it is not

heated above 250°C. Check that the chamfering on

the teeth is facing in the correct direction.

Loading...

Loading...