49

Crankshaft assembly

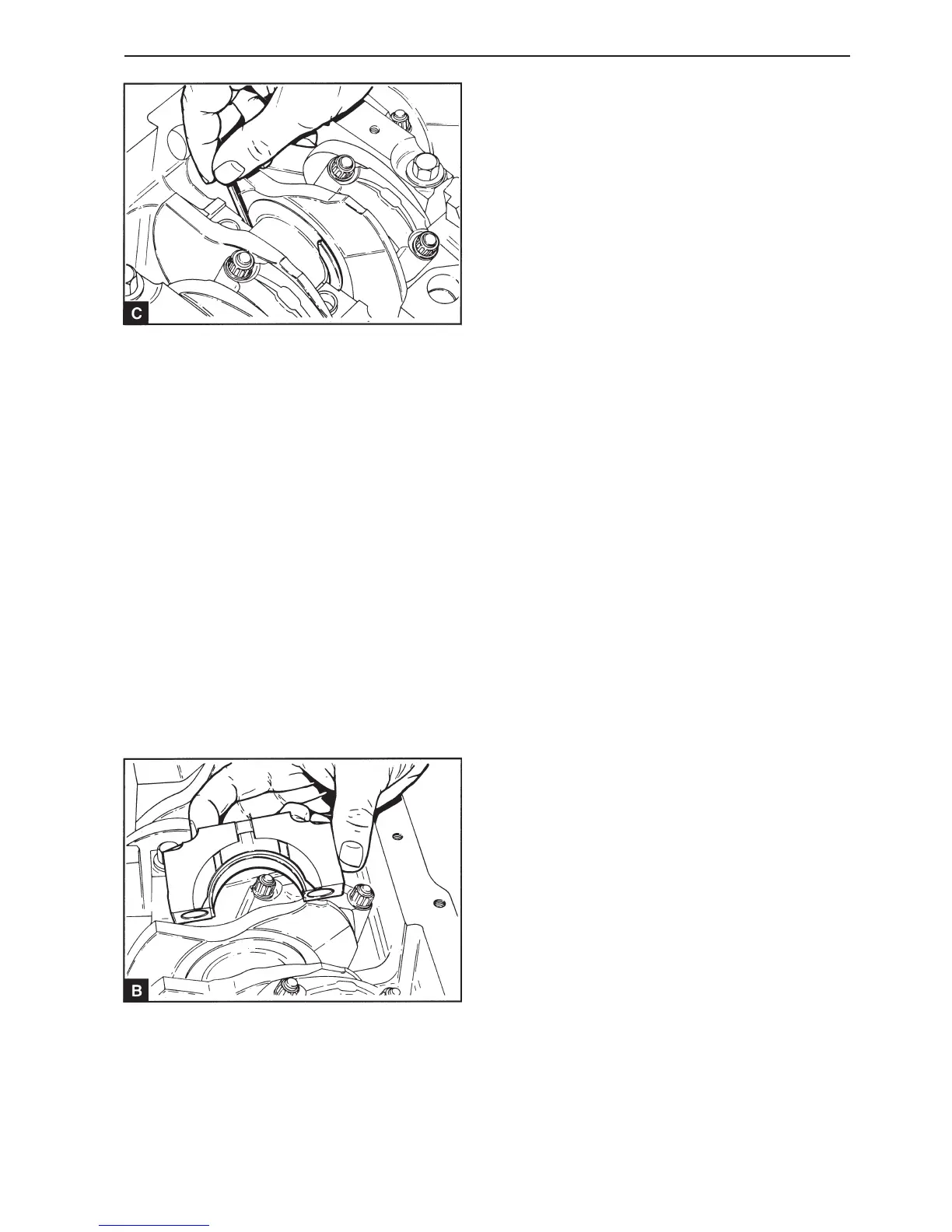

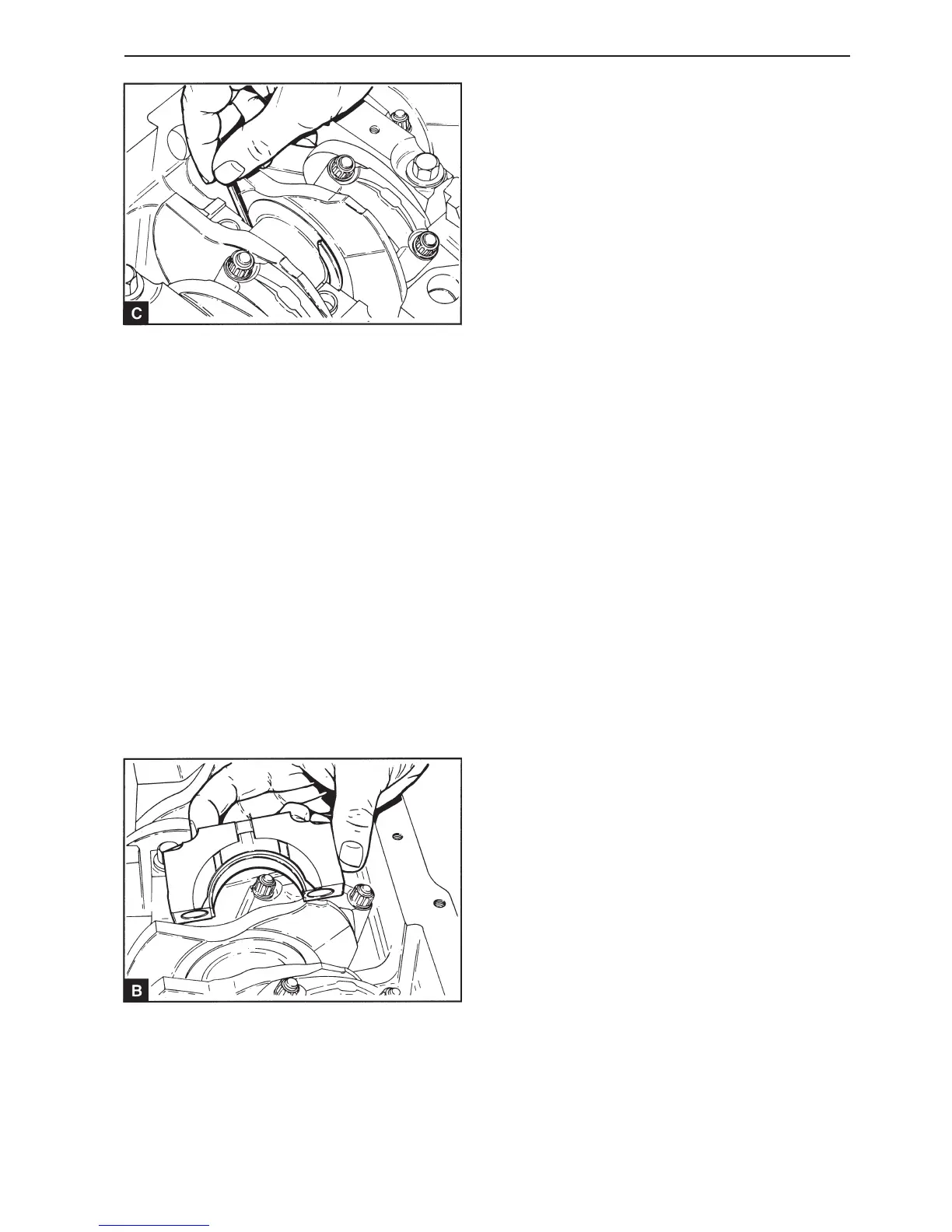

Remove the screws for the central main bearing

and remove the bearing cap assembly with the

three lower thrust washer halves (B). Press down

one end of each and every one of the upper thrust

washers with a suitable tool, made of soft material

so that the relevant thrust washer slides out of its

groove (C). If necessary move the crankshaft for-

wards or backwards to take the load off a thrust

washer which is trapped.

4

Lubricate the thrust washers with fresh engine oil.

5

Insert the upper thrust washer halves in their

grooves in the cylinder block. Check that the side of

thrust washer with the lubrication groove is turned

towards the crankshaft.

6

Install the lower thrust washer halves in the main

bearings with the lugs in their respective cut outs.

Check that the lubrication grooves in the thrust

washers are turned away from the bearing cap (B).

7

Check that the guide sleeves are correctly installed

in the bearing cap or in the cylinder block.

8

Check that the bearing shell is correctly installed in

the cap and that the main bearing journals are

clean. Lubricate the bearing shell with fresh engine

oil.

9

Install the bearing cap with the lugs for both bearing

shells turned in the same direction (14A.07/B1 and

B2). Tighten the screws for the main bearings in

stages and evenly to 112 Nm.

10

Check the axial clearance of the crankshaft. For the

correct axial clearance, see Workshop Manual,

“Technical data”

11

Install the oil screen and extractor pipe if required,

operation 18A-04.

12

Install the oil pan, operation 18A-03 and fill it to the

correct level with approved engine oil.

Loading...

Loading...