5-28 BA 1404 en – Edition 2.7 * * 1404b530.fm

Maintenance

Setting the tracks

The lubricating valve can be squeezed out due to the high grease pressure in

the hydraulic cylinder.

Injury hazard!

☞ Open the lubricating valve only very carefully and do not unscrew it more

than a revolution.

☞ Loosen no other component except the lubricating valve.

☞ Keep your face away from the lubricating valve connection.

➥ Contact your Wacker Neuson dealer if this does not reduce track tension.

☞ Release grease only as described below.

➥ Observe the safety instructions!

Excessive tension of the tracks causes serious damage to the cylinder and the track.

☞ Tighten the tracks only up to the prescribed measuring distance

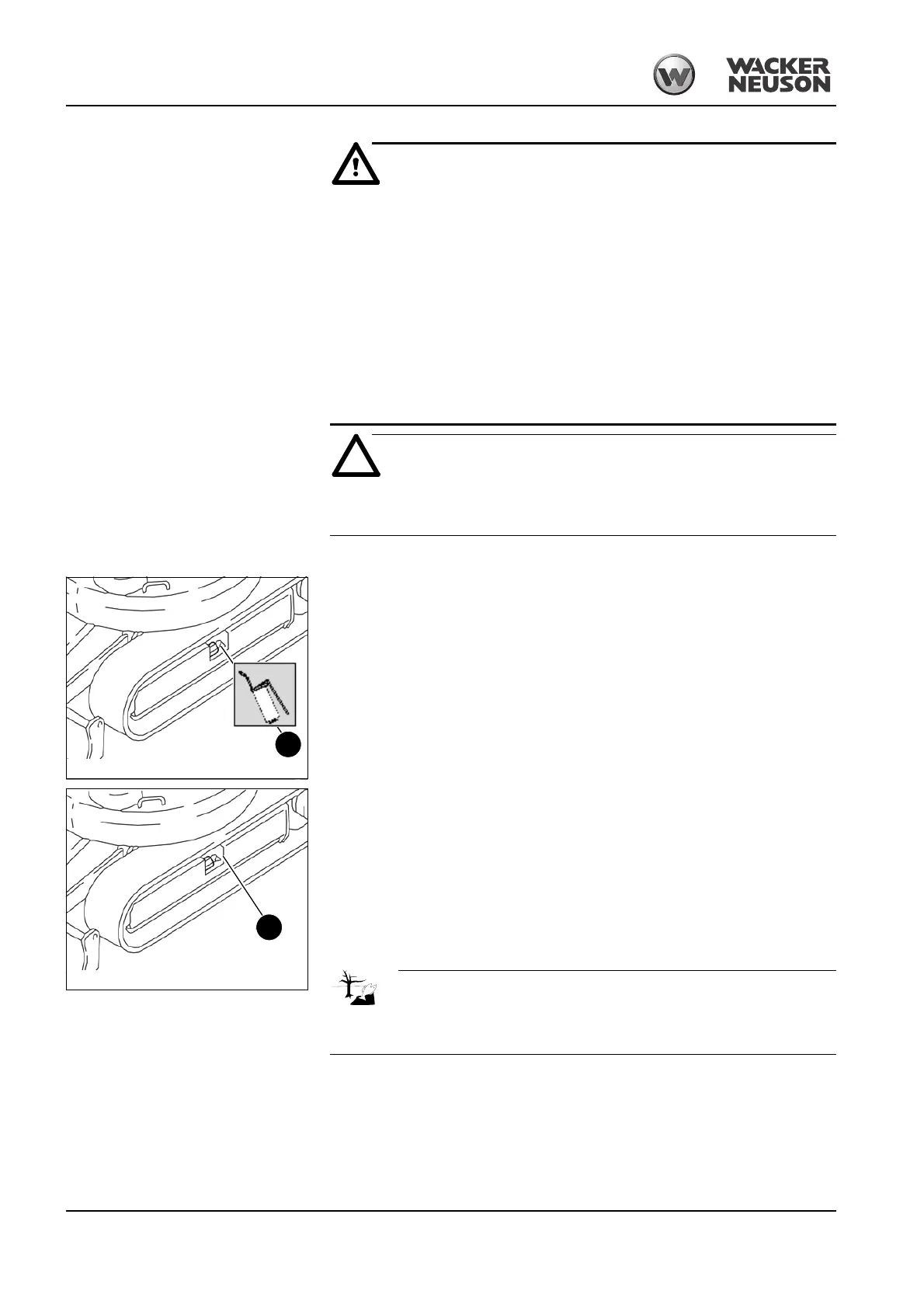

Tightening the tracks

☞ Inject grease with the pump through lubricating valve A.

☞ Check the tension is correct by starting the engine, letting it run at idling speed and

slowly moving the machine forward and reverse and switching it off again.

☞ Check the tension of the tracks again.

➥ If it is not correct:

☞ Adjust again.

☞ Should the tracks still be slack after injecting more grease, replace the tracks or the

seals in the cylinders. Contact a Wacker Neuson dealer in this case.

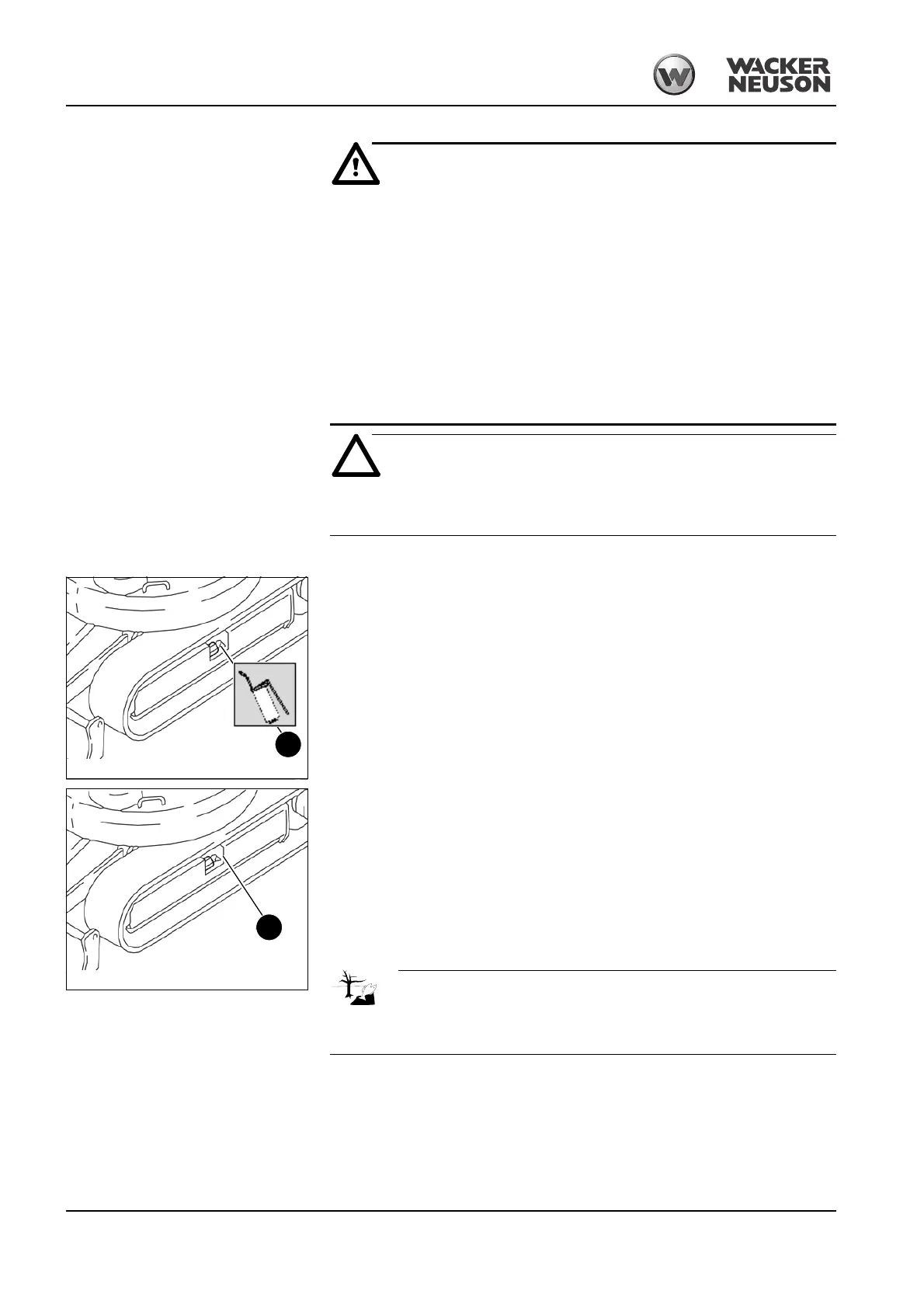

Reducing tension

☞ Place a suitable container underneath to collect the grease.

☞ Slowly turn lubricating valve A one revolution anticlockwise to release the grease.

☞ Retighten lubricating valve A.

➥ The grease flows out of the groove of the lubricating valve.

☞ Check the tension is correct by lowering the machine to the ground, starting the engine,

letting it run at idling speed without any load and slowly performing forward and reverse

machine travel and switching it off again. Raise the machine again with the boom.

☞ Check the tension of the tracks again.

Use a suitable container to collect the grease and dispose of it in an environ-

mentally friendly manner.

Abb. 213:Tightening the tracks

A

Abb. 214:Releasing grease

A

Loading...

Loading...