30~50 times 200~300 2000~2500 300~400

About 500

More than 50

times

About 200 About 3000

200~300 100~400

Note: the data in this table is the structure of 60/80 motor synchronous belt as an example.

5-4.DS5 adaptive mode

When the responsiveness requirement is not high, it can be used quickly only by setting functional parameters

such as gear ratio and enable, so as to save servo adjustment time. Adaptive function refers to the function that

can obtain stable response through automatic adjustment regardless of machine type and load fluctuation.

Servo on automatically starts adjustment.

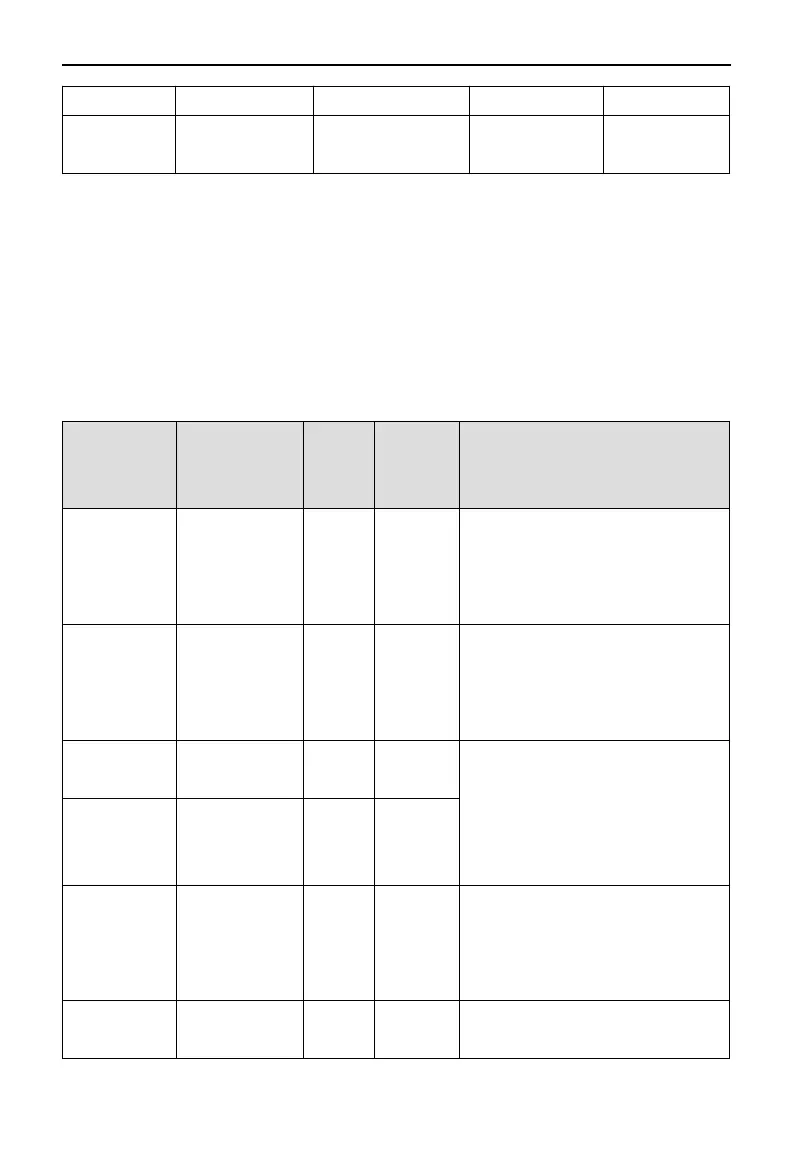

5-4-1.Adaptive mode parameter adjustment effect

parameter

Small inertia /

large inertia

Name

Default

value

setting

range

Effect

P2-05/P6-05

Adaptive speed

loop gain

400/200

200~400

Reducing can improve the capacity of

belt inertia, but it will reduce the

responsiveness and have a great impact

on the responsiveness

P2-07/P6-07

Adaptive load

inertia ratio

0/50

0~200

The capacity with inertia can be greatly

improved by increasing, and the

responsiveness will not be affected, and it is

easy to oscillate if it is too large

P2-08/P6-08

Adaptive speed

observer gain

60/40

30~60

Reducing P2-08 and increasing P2-12

can greatly improve the capacity with

inertia, but it will reduce the

responsiveness and have a great impact

on the responsiveness

P2-12/P6-12

Adaptive mode

stable maximum

inertia ratio

30/50

30~60

P2-10

Integral time

coefficient of

adaptive mode

speed loop

500

200~max

Adjust as needed, generally increase

P2-11 Adaptive mode

position loop

100

50~200

Adjust as needed to increase the

acceleration response and reduce the

60

Loading...

Loading...