Because it can only rotate in one direction, after a certain period of time, the number of revolving

cycles will always exceed the upper limit of absolute value encoder.

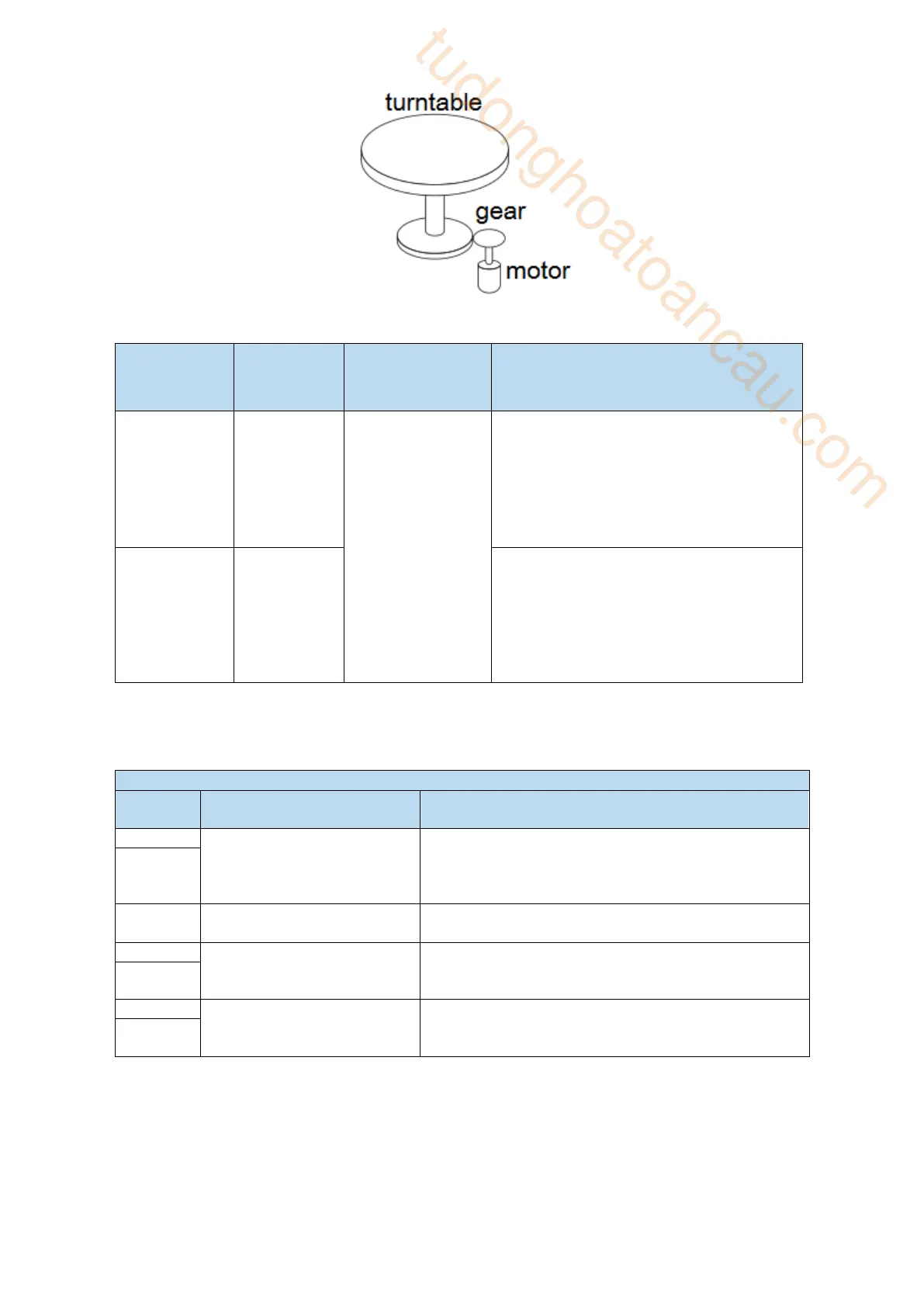

Resolution

(single-circle

data)

Rotating Circle

Serial Data

Output range

When it is higher than the upper limit value

in the forward direction (+32767*2^ 17):

Rotation serial data = 32767*2^17

When it is below the lower limit of reversal

direction (-32768*2^ 17):

Rotation Serial Data=-32767*2^17

When it is higher than the upper limit value

in the forward direction (+32767*2^23):

Rotation serial data = 32767*2^23

When it is below the lower limit of reversal

direction (-32768*2^ 23):

Rotation Serial Data=-32767*2^23

5.6.4 Read absolute position through communication

Absolute value single-turn position, read 0x100A and

0x100B hexadecimal address through Modbus RTU,

U0-10+ U0-11*10000 is present encoder single-turn

position

present turns of multi-turn

absolute

Read 0x105B hex address through ModbusRTU, which

is the current number of encoder turns;

absolute encoder present

position feedback low 32-bit

Read 0x1039 hex address through ModbusRTU

doubleword, which is the current encoder position, with

positive and negative pulses;

absolute encoder present

position feedback high 32-bit

Read 0x103B hexadecimal address through

ModbusRTU doubleword, which is the high bit of

current encoder and needs to add the low bit data;

Servo driver transmits position data information of encoder through RS485 port and Modbus RTU

protocol.

◼ 17-bit absolute value encoder has 131072 pulses per cycle.

First read the U0-60 (0x103C) value

(1) 0 means running in the positive direction. The current position of the encoder is

U0-57*1+U0-58*2^16.

tudonghoatoancau.com

Loading...

Loading...