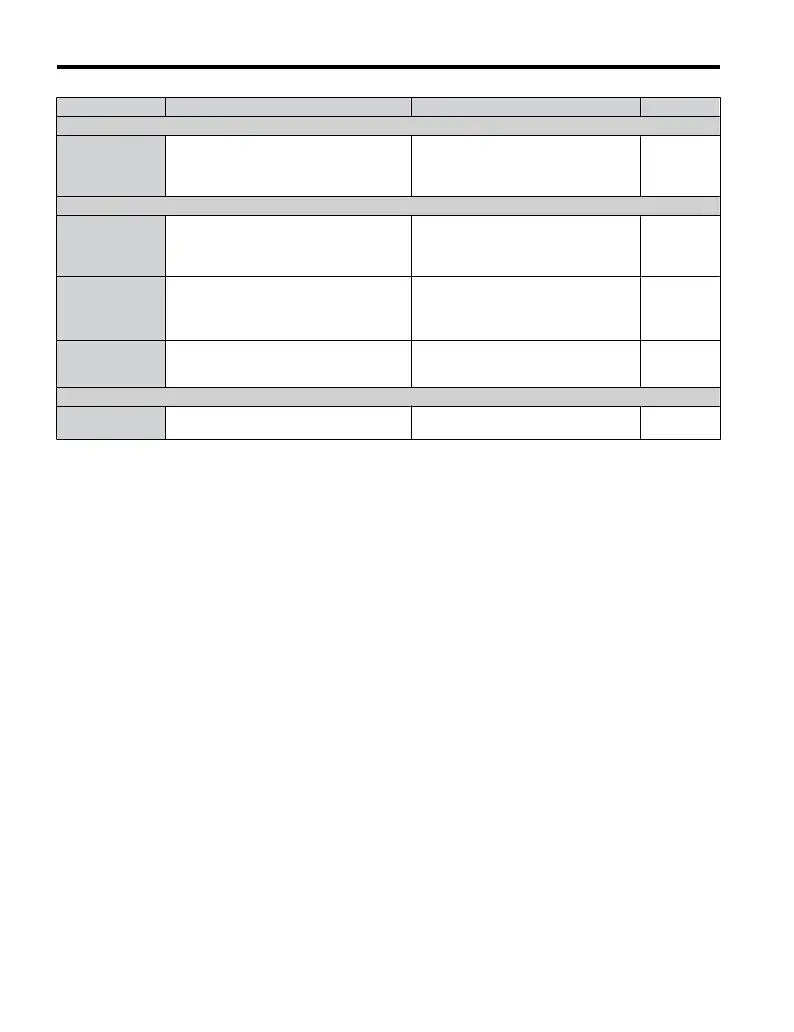

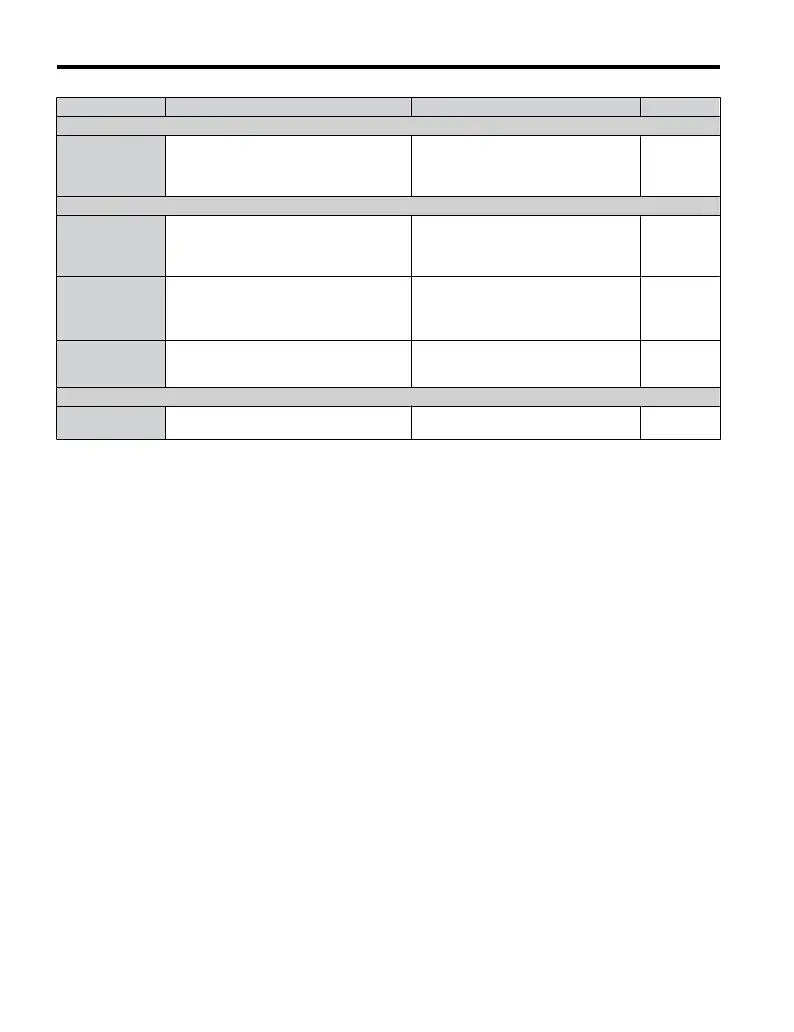

Inspection Area Inspection Points Corrective Action Checked

LED Periodic Inspection

LEDs

• Make sure the LED lights correctly.

• Inspect for dust or other foreign material

that may have collected on surrounding

components.

• Contact your Yaskawa representative

if there is any trouble with the LED

or keypad.

• Clean the LED.

Cooling System Periodic Inspection

Cooling Fan

• Check for abnormal oscillation or

unusual noise.

• Check for damaged or missing fan

blades.

• Replace as required.

• Refer to Drive Cooling Fans on

page 161 for information on cleaning

or replacing the cooling fan.

Heatsink

• Inspect for dust or other foreign material

collected on the surface.

• Use dry air to clear away foreign

matter.

•

Use a pressure of 39.2 x 10

4

to 58.8 x

10

4

Pa (4 - 6 kg•cm

2

).

Air Duct

• Inspect air intake and exhaust openings.

They must be free from obstruction and

properly installed.

• Visually inspect the area.

• Clear obstructions and clean air duct

as required.

Motor Periodic Inspection

Operation Check

• Check for increased vibration or

abnormal noise.

• Stop the motor and contact qualified

maintenance personnel as required.

Note: Periodic inspections should be performed every one or two years. The drive, however, may require more

frequent inspection due to poor environments or rigorous use.

6.2 Inspection

158

YASKAWA ELECTRIC TOEP C710606 25B YASKAWA AC Drive J1000 Installation & Start-Up Manual

2/6/2008-14:44

Loading...

Loading...